Plugging agent with characteristic of controlled and delayed expansion, and preparation method thereof

A delayed expansion and plugging agent technology, applied in the field of plugging aids, can solve the problems of reduced expansion performance and achieve the effects of delayed expansion, improved lost formation, and improved temperature resistance and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] First weigh 6g of sodium bentonite, 20g of acrylic acid, 10g of 2-acrylamido-2-methylpropanesulfonic acid, 0.03g of N,N-methylenebisacrylamide and 0.015g of initiator ammonium persulfate into the reactor, Add 150g of distilled water, stir in an ice-water bath until completely dissolved, pass N 2 Protection; when the temperature drops to about 5°C, slowly add 10g of initiator sodium sulfite solution (sodium sulfite 0.015g) dropwise; after dropping, continue to stir for 20min, stop stirring, slowly raise the temperature to 45°C, and statically react for 3h to obtain an elastic gel body; take it out, dry it in vacuum at 70°C, and shear it to obtain a water-absorbing swellable resin; weigh 5g of the resin and put it into a reactor, add 20g of n-butanol and 0.025g of solid acid catalyst in turn, react at 120°C for 4h, and filter and drying to obtain the No. 1 product of controllable delayed expansion plugging agent.

Embodiment 2

[0021] First weigh 5g of sodium bentonite, 25g of acrylic acid, 10g of 2-acrylamido-2-methylpropanesulfonic acid, 0.04g of N,N-methylenebisacrylamide and 0.015g of initiator ammonium persulfate into the reactor, Add 200g of distilled water, stir in an ice-water bath until completely dissolved, pass N 2 Protection; when the temperature drops to about 5°C, slowly add 10g of initiator sodium sulfite solution (sodium sulfite 0.015g) dropwise; after dropping, continue to stir for 20min, stop stirring, slowly raise the temperature to 50°C, and statically react for 2h to obtain an elastic gel body; take it out, dry it in vacuum at 70°C, and shear it to obtain a water-absorbing swellable resin; weigh 5g of the resin and put it into a reactor, add 20g n-octanol and 0.025g solid acid catalyst in turn, react at 150°C for 3h, and filter and drying to obtain the No. 2 product of controllable delayed expansion plugging agent.

Embodiment 3

[0023] First weigh 5g of sodium bentonite, 30g of acrylic acid, 18g of 2-acrylamido-2-methylpropanesulfonic acid, 0.05g of N,N-methylene bisacrylamide and 0.02g of initiator ammonium persulfate into the reactor, Add 200g of distilled water, stir in an ice-water bath until completely dissolved, pass N 2 Protection; when the temperature drops to about 5°C, slowly add 10g of initiator sodium sulfite solution (sodium sulfite 0.02g) dropwise; after dropping, continue to stir for 20min, stop stirring, slowly raise the temperature to 50°C, and statically react for 3h to obtain an elastic gel body; take it out, dry it in vacuum at 70°C, and shear it to obtain a water-absorbing swellable resin; weigh 5g of the resin and put it into a reactor, add 15g of dodecanol and 0.02g of solid acid catalyst in turn, react at 150°C for 4h, and filter and drying to obtain the No. 3 product of controllable delayed expansion plugging agent.

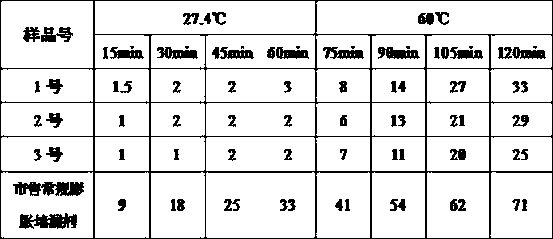

[0024] The above three products were tested for water-swellin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap