Cantilever type polar coordinate feeding 3D printer

A 3D printer and polar coordinate technology, applied in the field of 3D printing, can solve problems such as inability to achieve energy saving effects, multiple power sources, and heavy weight, and achieve high engineering practical value, simple structure, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

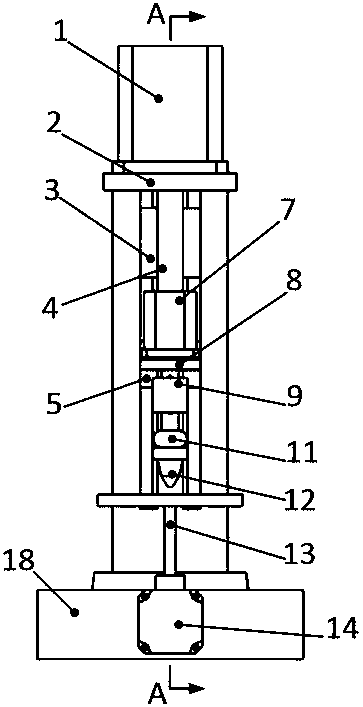

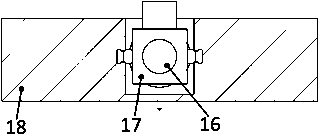

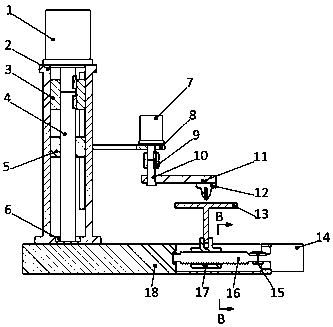

[0013] The implementation process of the present invention will be described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 , figure 2 and image 3 As shown, a cantilever type polar coordinate feeding 3D printer includes a base motor 1, a base shell 2, a base coupling 3, a lead screw 4, a nut 5, a bearing 6, a cantilever motor 7, a bracket 8, a cantilever coupling Shaft device 9, connecting rod 10, cantilever 11, printing nozzle 12, printing platform 13, motor 14, coupling 15, screw rod 16, sliding nut 17, base 18; The base motor 1 is installed on the upper side of the base housing 2 through bolts, the motor shaft of the base motor 1 and the side with the keyway of the lead screw 4 are connected by a key through the base coupling 3, and the other side of the lead screw 4 is installed on the Supported in the bearing 6 at the bottom of the machine base shell 2, the screw 4 is fitted with a nut 5, and the bracket 8 protruding from the nut 5 protru

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap