Test device and test method for simulating soil mass column hole expansion

A test device and soil simulation technology, applied in the field of geotechnical engineering, can solve problems such as remodeling, difficult to solve complex strata, disturbance, etc., and achieve the effects of strong operability, ingenious test methods, and improved test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

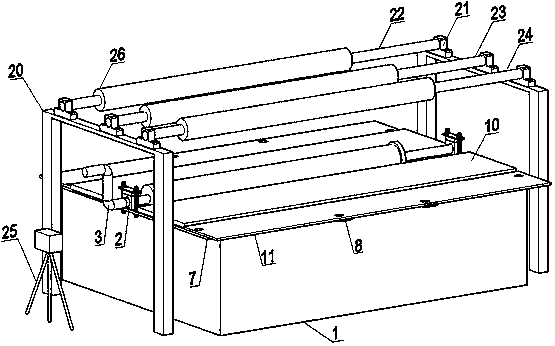

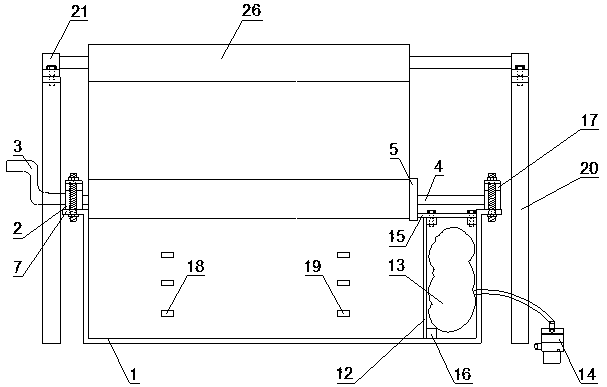

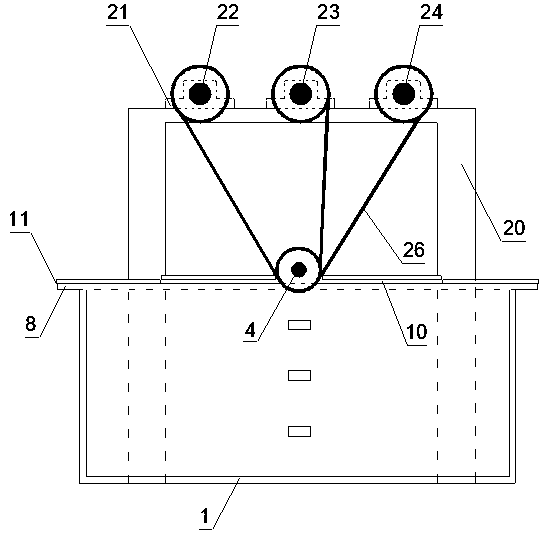

[0040] Such as Figure 1~7As shown, the present invention provides a kind of test device for simulating the expansion of column holes in soil, including model box 1, portal frame 20, soil squeezing device, high-speed camera 25, confining pressure device and data acquisition device;

[0041] Described model box 1 is cuboid structure, and one short side of it adopts toughened glass plate to make, and high-speed camera 25 faces this transparent glass surface, and the short side length of model box 1 must satisfy the need to eliminate box wall to soil column hole expansion. Influence: the short side direction of the box top of the model box 1 is provided with a first outrigger plate 7, and two second outrigger plates 8 are arranged at equal intervals in the long side direction;

[0042] The door-shaped support 20 stands on both sides of the short side direction of the model box 1, and the door-shaped support 20 is composed of a crossbeam and two columns, and the bottom of the column

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap