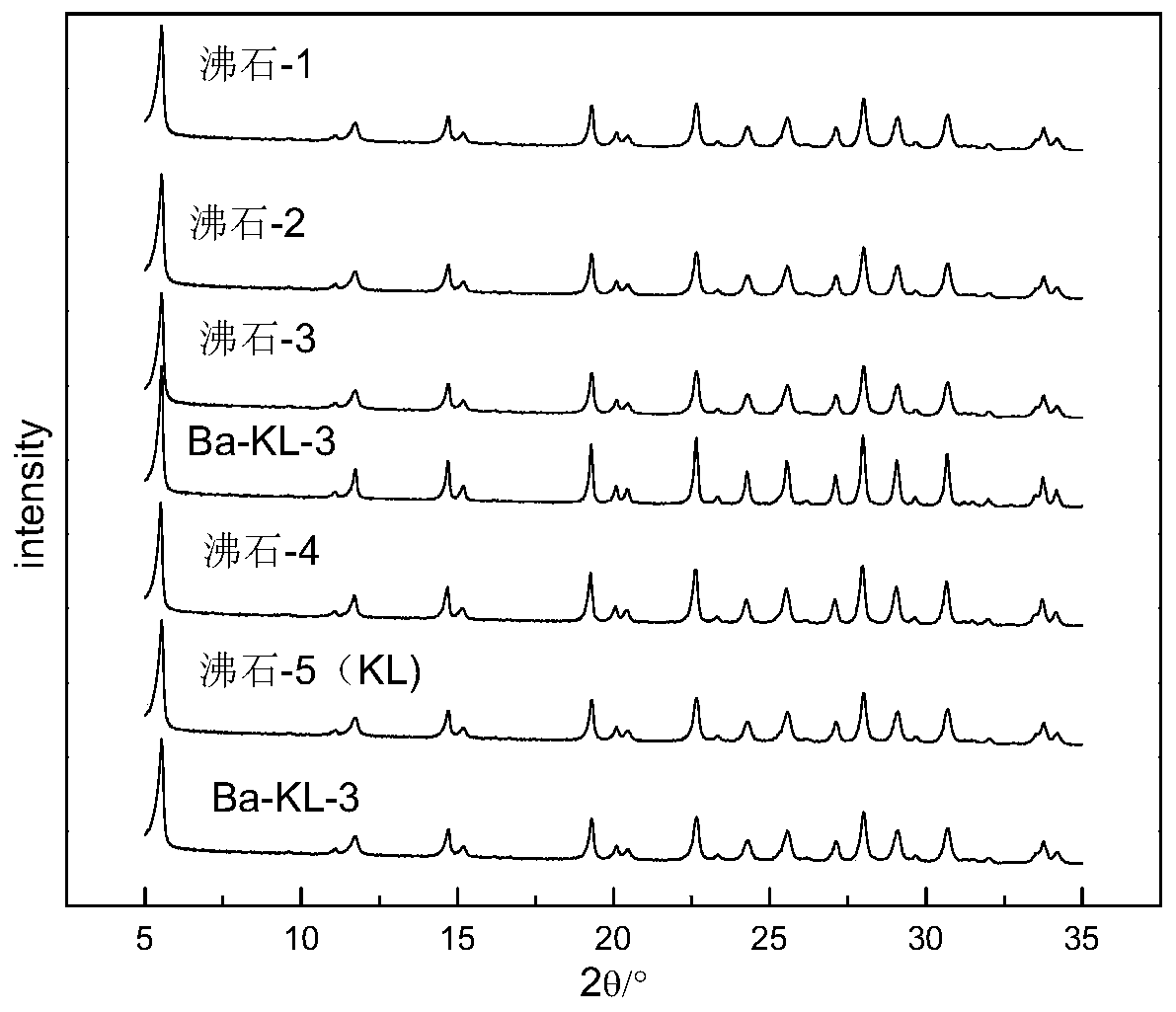

BaKL zeolite rich in mesopores and preparation method of BaKL zeolite

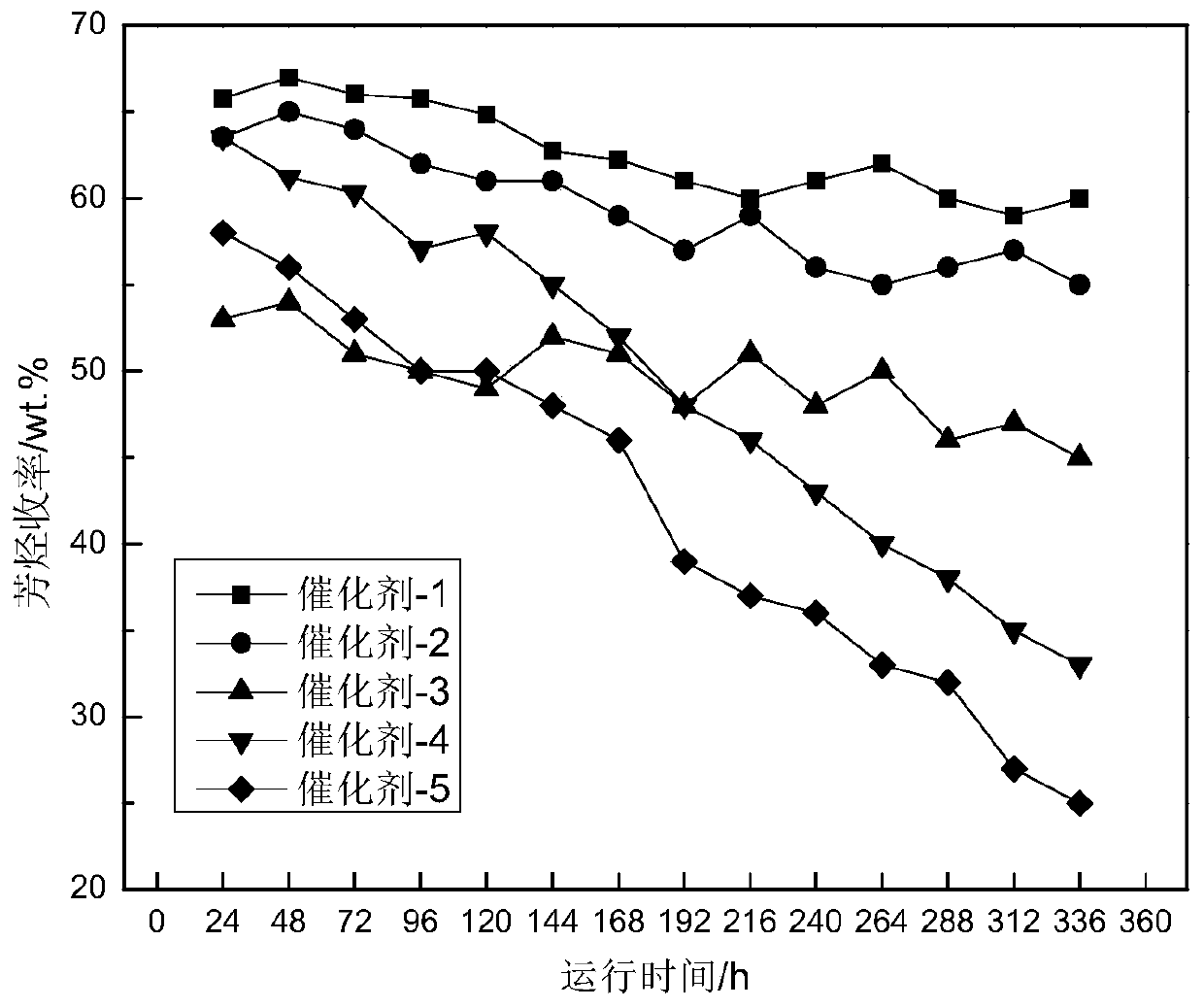

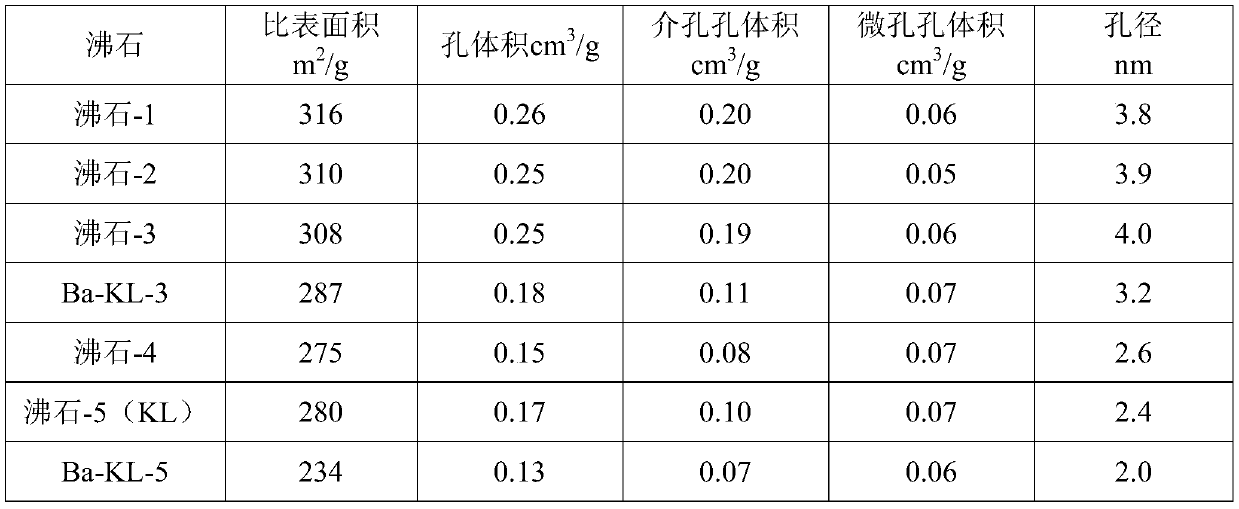

A zeolite and mesoporous technology, which is applied in the fields of BaKL zeolite rich in mesopores and its preparation, catalyst carrier and its preparation, can solve the problems such as the large influence of molecular sieve framework structure, and avoid the reduction of specific surface area and pore volume, The effect of increasing the number of mesopores and excellent yield of aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] According to the molar ratio of oxides, it is 6K 2 O: Al 2 o 3 :14SiO2 2 :180H 2 O: 0.06BaO was fed, stirred evenly at 25°C, and then statically aged at 35°C for 48 hours to prepare the guiding agent. The silicon source was silica sol, the aluminum source was aluminum hydroxide, the alkali source was potassium hydroxide, and the barium source was nitric acid. Barium; 4K by molar ratio of oxide 2 O: Al 2 o 3 : 16SiO 2 : 200H 2 O, the silicon source is silica sol, the aluminum source is aluminum hydroxide, the alkali source is potassium hydroxide, add polyethylene glycol-20000 and directing agent according to the mass ratio of solid matter 10% and 25% respectively, fully stir evenly, stir After 2 hours, it was transferred to a crystallization kettle, crystallized at 150°C for 48 hours, and then filtered, washed, dried, and roasted to obtain a BaKL zeolite rich in mesoporous pores, which was designated as Zeolite-1, and the mass content of Ba element was 0.3wt.%. At

Embodiment 2

[0035] According to the molar ratio of oxides, it is 18K 2 O: Al 2 o 3 :20SiO2 2 :300H 2 O: 0.12BaO was fed, stirred evenly at 25°C, and then statically aged at 35°C for 48 hours to prepare the guiding agent. The silicon source was silica sol, the aluminum source was aluminum hydroxide, the alkali source was potassium hydroxide, and the barium source was nitric acid. Barium; 10K by molar ratio of oxide 2 O: Al 2 o 3 : 21SiO 2 : 250H 2 O, the source of silicon is silica sol, the source of aluminum is aluminum hydroxide, and the source of alkali is potassium hydroxide. Add methyl cellulose and guiding agent according to the mass ratio of solid matter at 7% and 16%, stir well, and stir for 2 hours. Transfer to a crystallization tank, crystallize at 150°C for 48 hours, filter, wash, dry, and roast to obtain a mesoporous-rich BaKL zeolite, which is recorded as Zeolite-2, and the mass content of Ba element is 0.6wt.%. Use platinum dichlorotetraammine solution to exchange with

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap