DC transformer based on centralized multi-winding high-frequency transformer, and control method

A technology of DC transformers and high-frequency transformers, applied in the direction of converting DC power input to DC power output, control/regulation systems, instruments, etc., can solve the difficulty of further improving the power density of DC transformers, and the increase in the number of switching devices and high-frequency transformers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

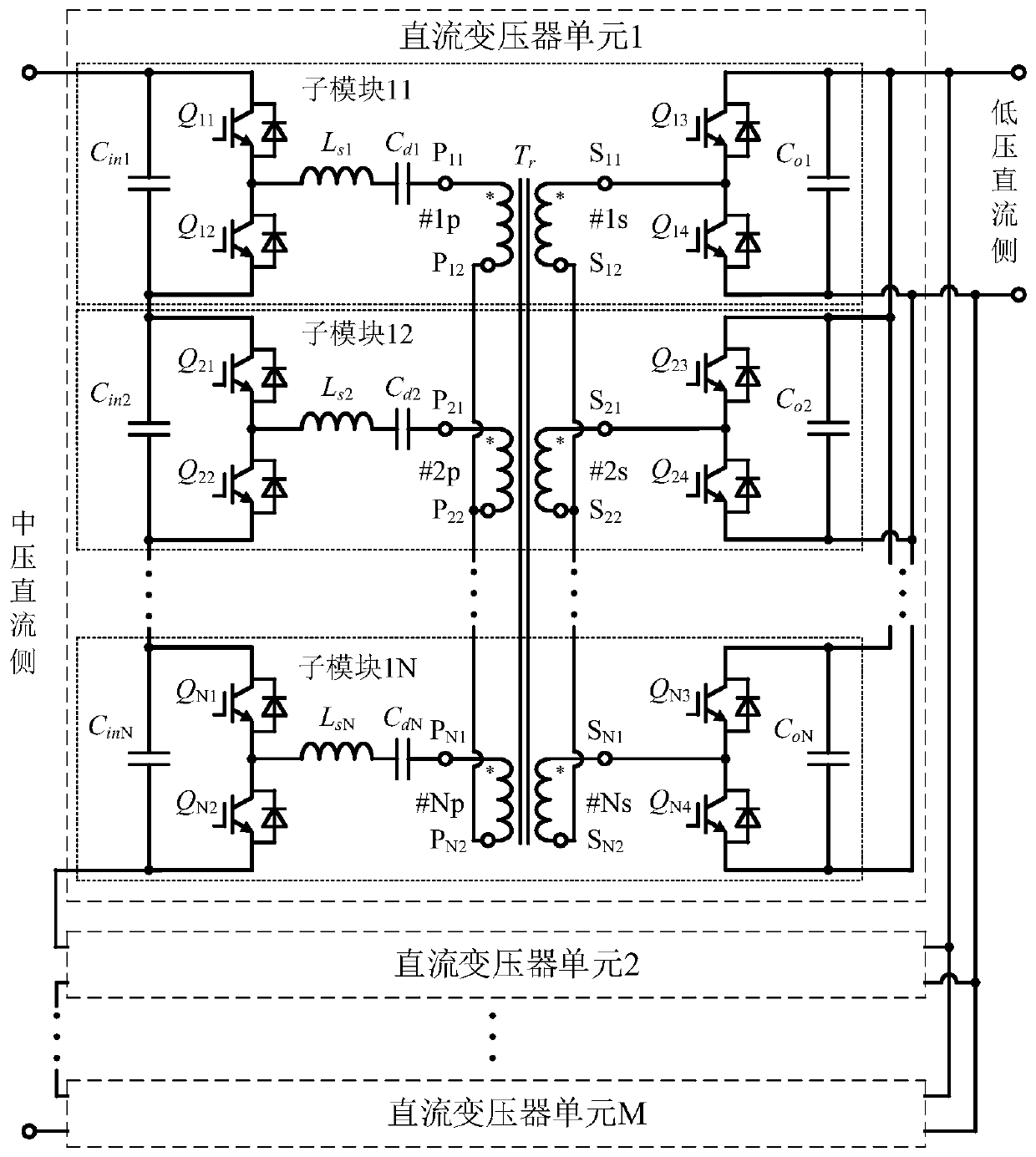

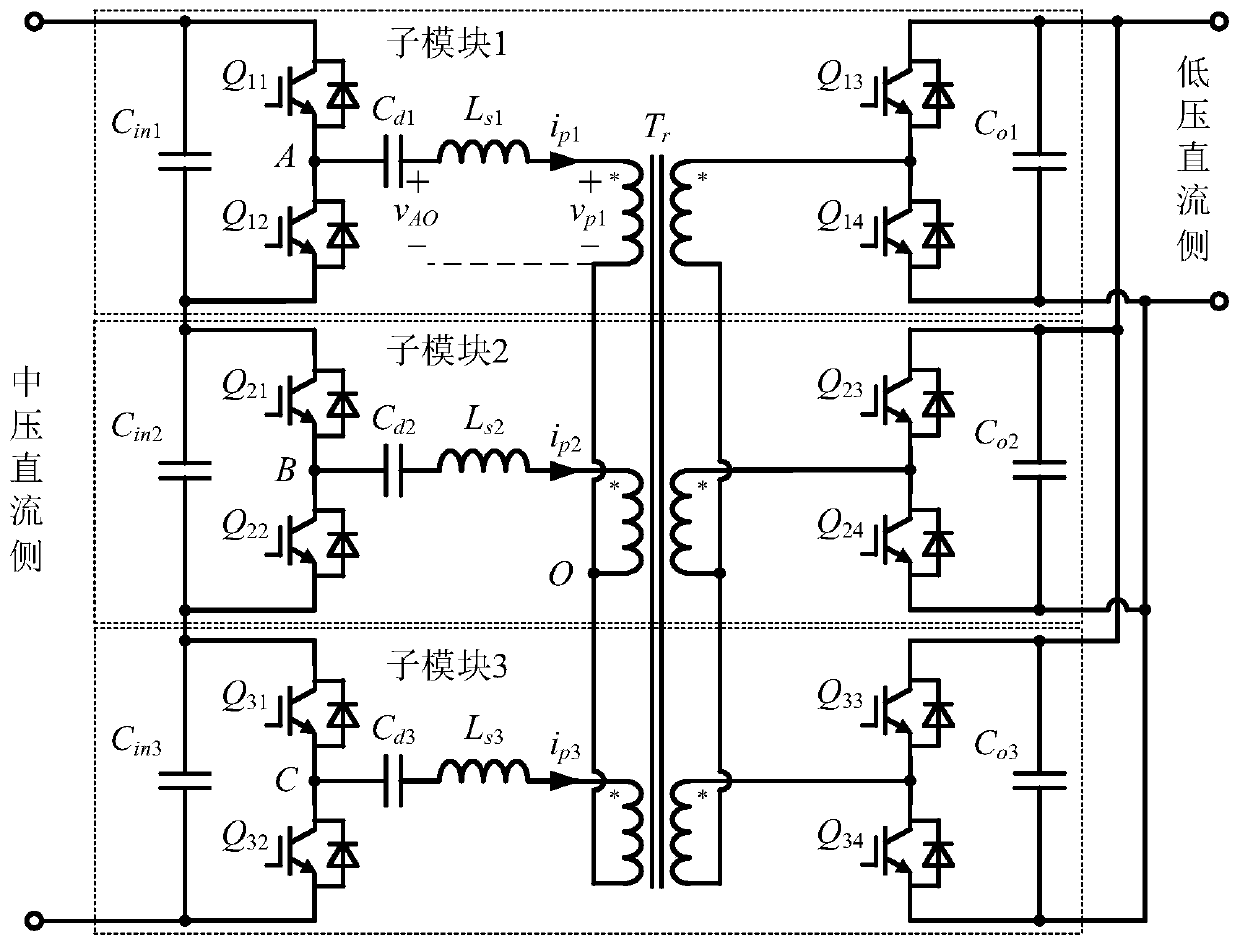

[0028] The invention designs a DC transformer based on a centralized multi-winding high-frequency transformer. Such as figure 1 As shown, the DC transformer topology is composed of M DC transformer units with input in series and output in parallel (ISOP), and each DC transformer unit contains N (N≥3) sub-modules with input in series and output in parallel. Contains an input filter capacitor C on the MV DC side ini , a bridge arm consisting of two switching tubes connected in series, and a transmission inductance L si , a DC blocking capacitor C di with the primary winding of the transformer. Contains an output filter capacitor C on the low voltage DC side oi , a bridge arm composed of two switch tubes in series and the secondary winding of the transformer.

[0029] In the i-th sub-module of the j-th DC t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap