High-pressure pump

A technology for high-pressure pumps and fuel oil, applied in pump components, fuel injection pumps, fuel injection devices, etc., can solve problems such as increasing the volume of high-pressure pumps, and achieve the effect of small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

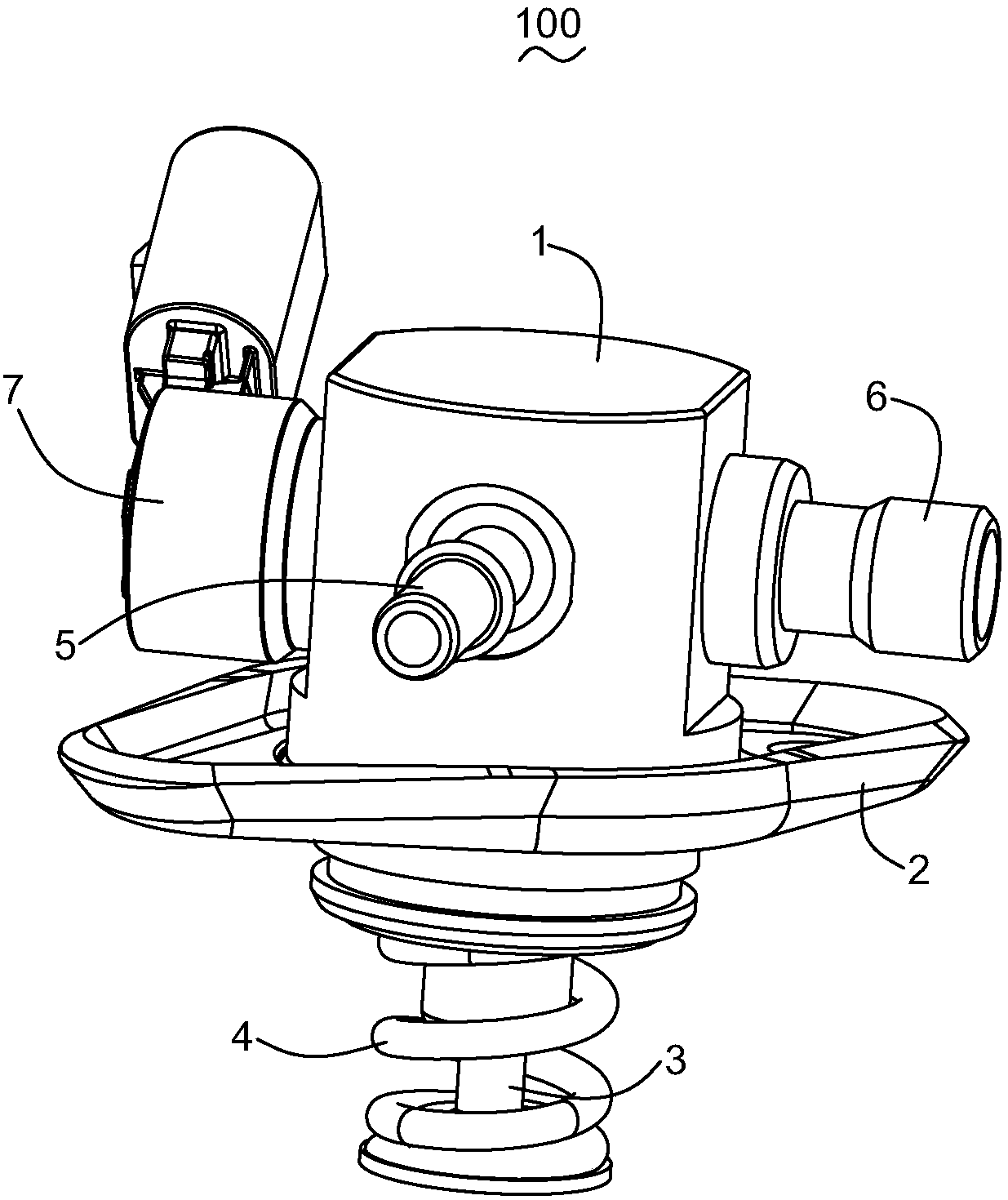

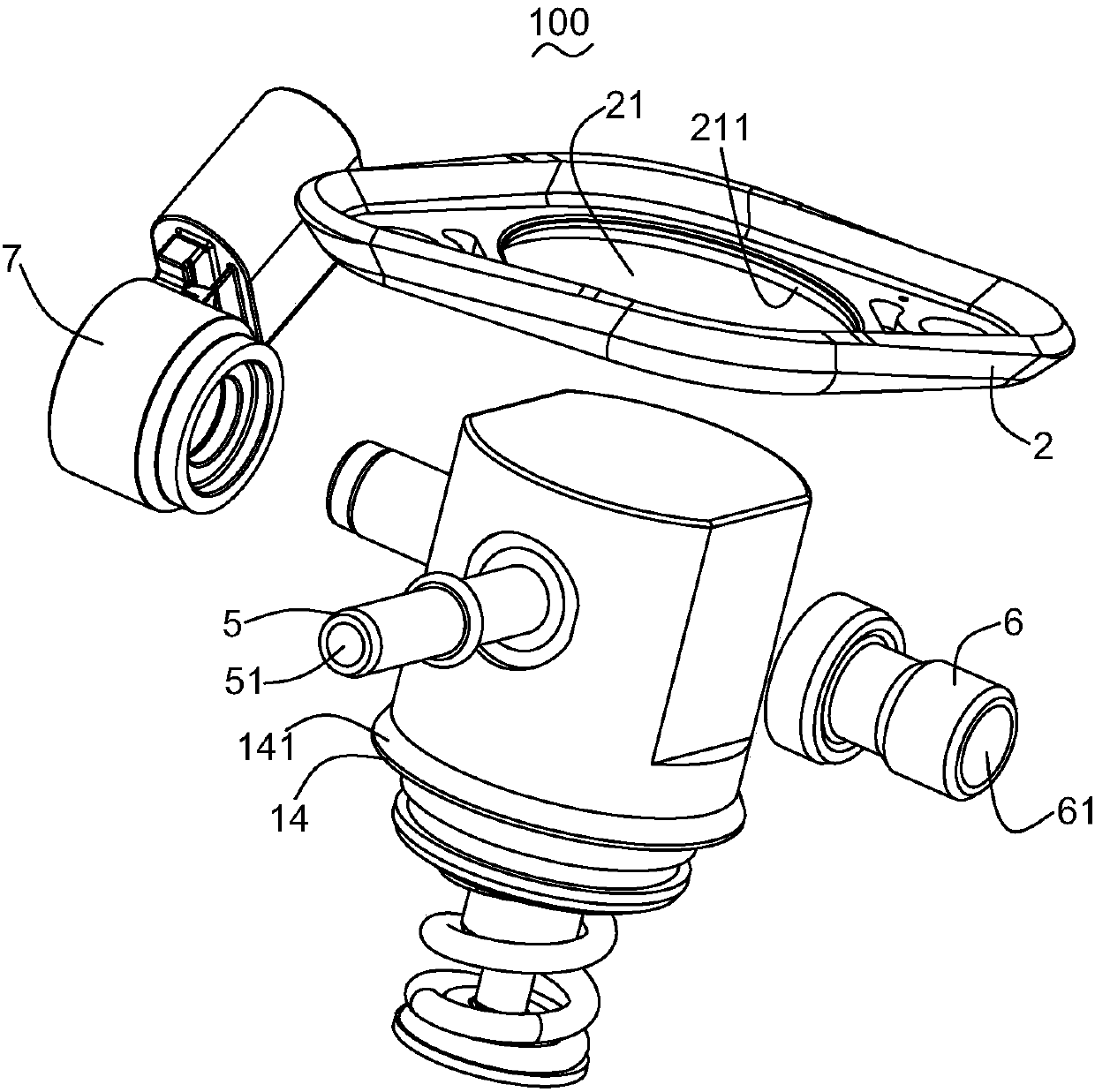

[0024] see Figure 1 to Figure 5 As shown, the present invention provides a high-pressure pump 100, which includes a housing 1, a plunger 3, a fixing member 2, a spring 4, a fuel inlet port 5, a fuel outlet port 6, a solenoid valve control port 7, a damper 8 and a seal Holder 9. The fuel inlet port 5 is provided with a fuel inlet channel 51 , and the fuel outlet port 6 is provided with a fuel outlet channel 61 . A fuel inlet port 5 and a fuel outlet port 6 are fixed to the housing 1 .

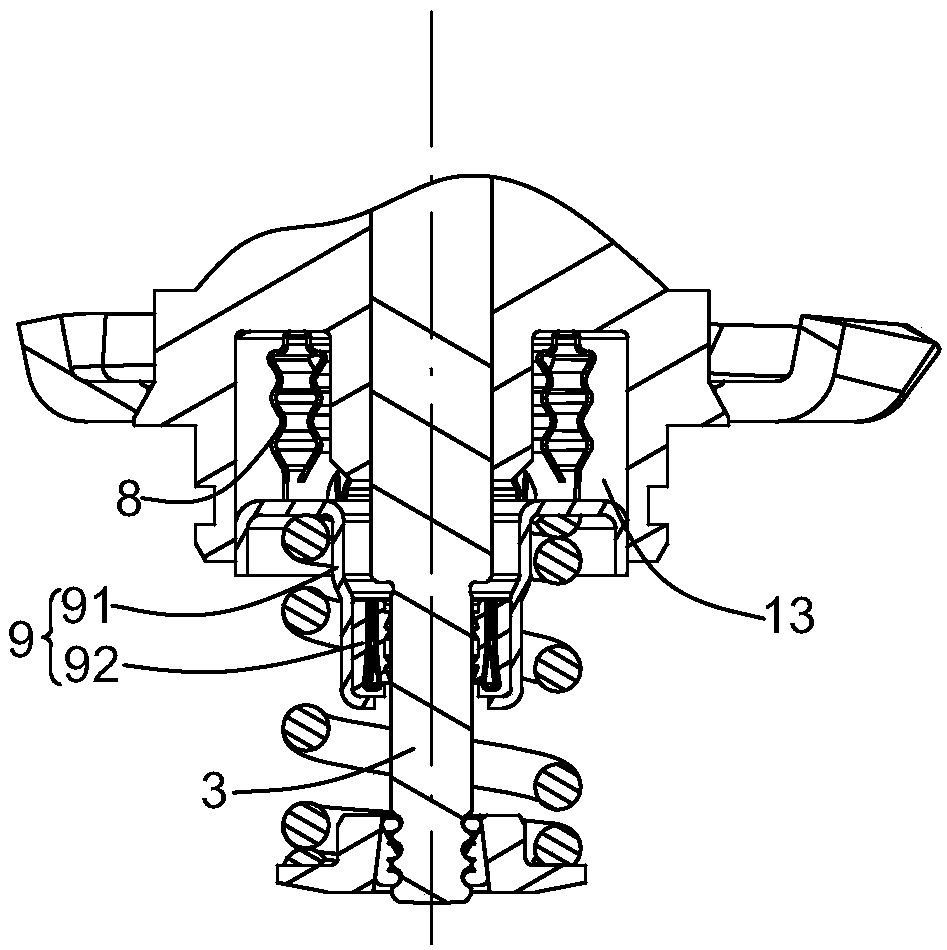

[0025] The housing 1 is provided with a central axis L. As shown in FIG. The housing 1 includes a plunger channel 12 , a plunger cavity 11 connected to the plunger channel 12 and a protruding portion 14 extending outward. The protruding portion 14 has a first mating surface 141 . The housing 1 also includes a buffer chamber 13 arranged around the plunger passage 12 and a connecting passage 14 connecting the buffer chamber 13 with the fuel inlet passage 51 . The damper 8 is fixed in the buffer

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap