Preparation method of pH-responsive quick self-repairing collagen-based hydrogel with adhesivity, antibiosis and pressure resistance

An adhesive and self-healing technology, applied in the field of medical material manufacturing, can solve the problems of bound molecular chain mobility, lack of self-healing ability, shortening the life of hydrogel implants, etc., to broaden the application range and service life, The effect of good pH intelligent responsiveness and rapid self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

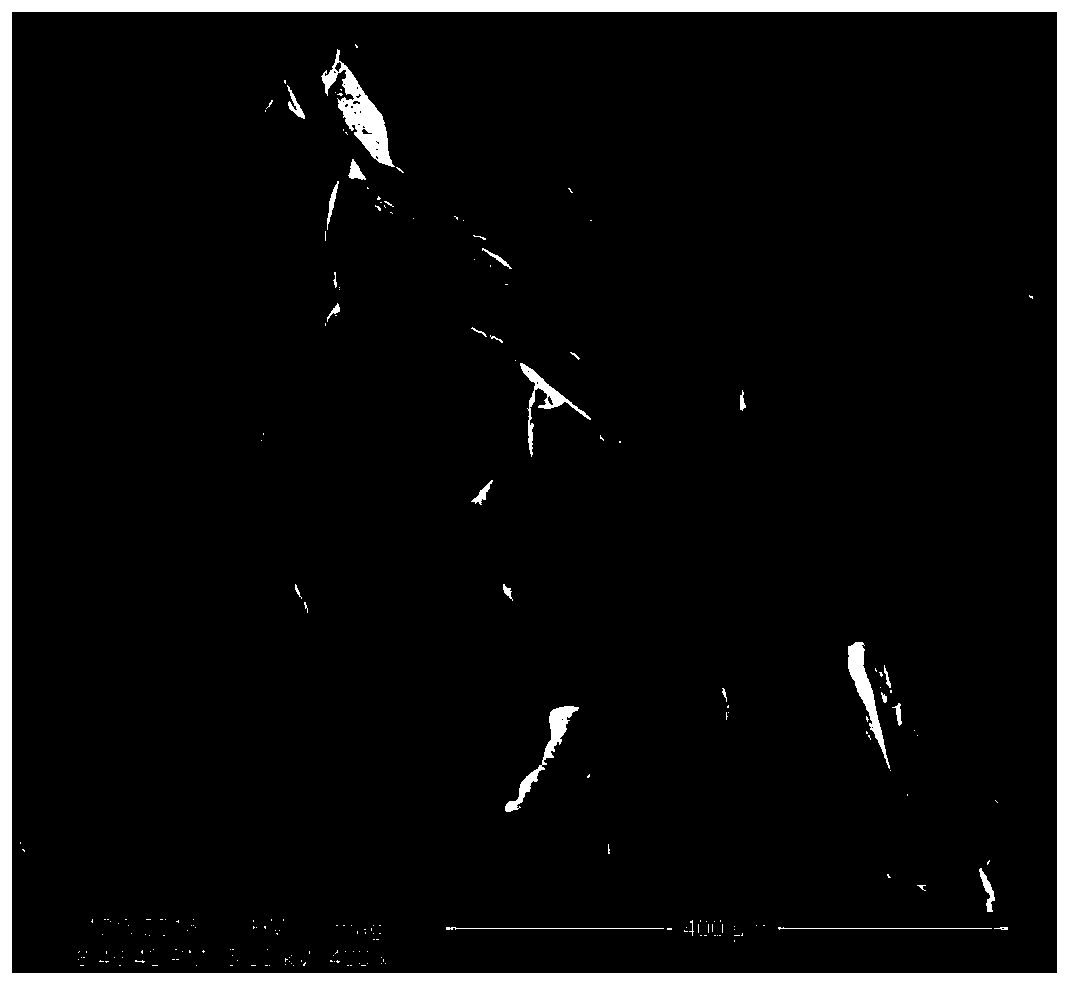

Image

Examples

Embodiment 1

[0024] Weigh 1.0g PEG2000, 0.3g 4-formylbenzoic acid and 0.015g dimethylaminopyridine and dissolve in 30mL tetrahydrofuran, add 0.5g N,N'-dicyclohexylcarbodiimide in nitrogen atmosphere, 23℃ After stirring for 12 hours, a white solid was obtained by filtration; the white solid was dissolved in 30 mL of tetrahydrofuran, precipitated in diethyl ether, and dried to obtain DA-PEG; the DA-PEG was dissolved in water to prepare a concentration of 20 mg / mL DA-PEG solution;

[0025] Dissolve chitosan powder in 0.01mol / L acetic acid solution to prepare a 10mg / mL chitosan solution, and store it in cold storage; under ice bath conditions, dissolve the lyophilized collagen sponge in 0.01mol / L acetic acid solution, Prepare a collagen solution of 10 mg / mL and store it in cold storage; under ice bath conditions, weigh the collagen solution and the chitosan solution and mix them at a mass ratio of 3:1, stir and vacuum defoam for 5 minutes, and ultrasonically Obtain a uniform collagen /

Embodiment 2

[0032] Weigh 3.0g PEG2000, 0.9g 4-formylbenzoic acid and 0.045g dimethylaminopyridine and dissolve in 90mL tetrahydrofuran, add 1.5g N,N'-dicyclohexylcarbodiimide in nitrogen atmosphere, 25℃ After stirring for 15 hours, a white solid was obtained by filtration; the white solid was dissolved in 90 mL of tetrahydrofuran, precipitated in diethyl ether, and dried to obtain DA-PEG; the DA-PEG was dissolved in water to prepare a concentration of 50 mg / mL DA-PEG solution;

[0033] Dissolve chitosan powder in 0.25mol / L acetic acid solution to prepare a 20mg / mL chitosan solution and store it in cold storage; under ice bath conditions, dissolve the freeze-dried collagen sponge in 0.25mol / L acetic acid solution, Prepare a collagen solution of 20 mg / mL and store it in cold storage; under ice bath conditions, weigh the collagen solution and the chitosan solution and mix them at a mass ratio of 1:1, stir and vacuum defoam for 10 min, and ultrasonically Obtain a uniform collagen / ch

Embodiment 3

[0036] Weigh 5.0g PEG2000, 1.5g 4-formylbenzoic acid and 0.075g dimethylaminopyridine and dissolve in 150mL tetrahydrofuran, add 2.5g N,N'-dicyclohexylcarbodiimide in nitrogen atmosphere, 28°C After stirring for 24 hours, a white solid was obtained by filtration; the white solid was dissolved in 30 mL of tetrahydrofuran, precipitated in diethyl ether, and dried to obtain DA-PEG; the DA-PEG was dissolved in water to prepare a concentration of 80 mg / mL DA-PEG solution;

[0037] Dissolve chitosan powder in 0.5mol / L acetic acid solution to prepare a 30mg / mL chitosan solution and store it in cold storage; under ice bath conditions, dissolve the freeze-dried collagen sponge in 0.5mol / L acetic acid solution, Prepare a collagen solution of 30 mg / mL and store it in cold storage; under ice bath conditions, weigh the collagen solution and the chitosan solution and mix them at a mass ratio of 1:3, stir and vacuum defoam for 15 minutes, and ultrasonically Obtain a uniform collagen

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap