Wheel brush lifting equipment of car washer

A technology of lifting equipment and car washing machine, which is applied in vehicle cleaning equipment, vehicle maintenance, vehicle cleaning, etc. It can solve the problems of time-consuming and labor-consuming artificial water spraying, large consumption of functions, and large impact force of water contacting the car body, etc., to achieve Save water, manpower and material resources, increase service life and reduce work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

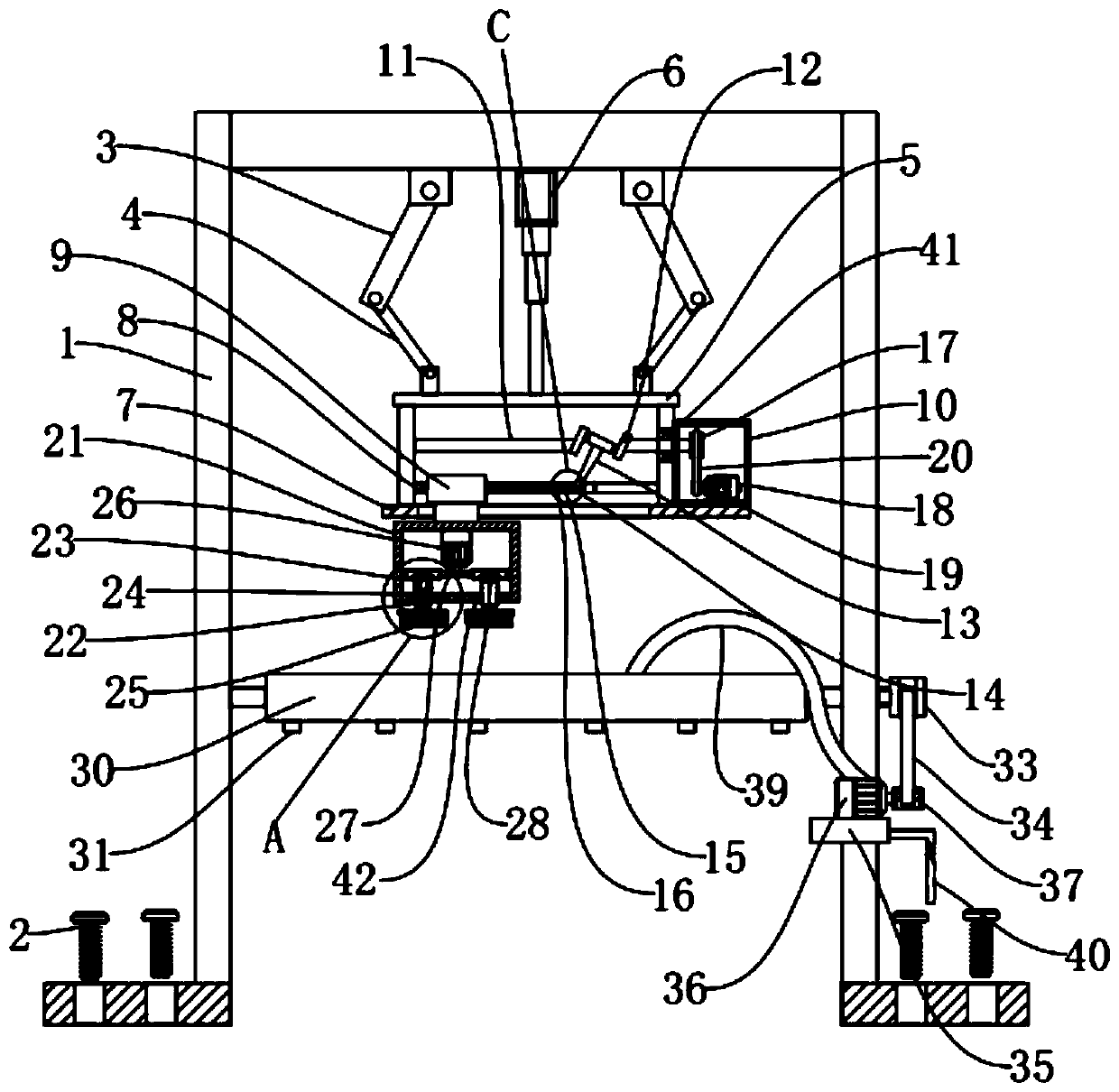

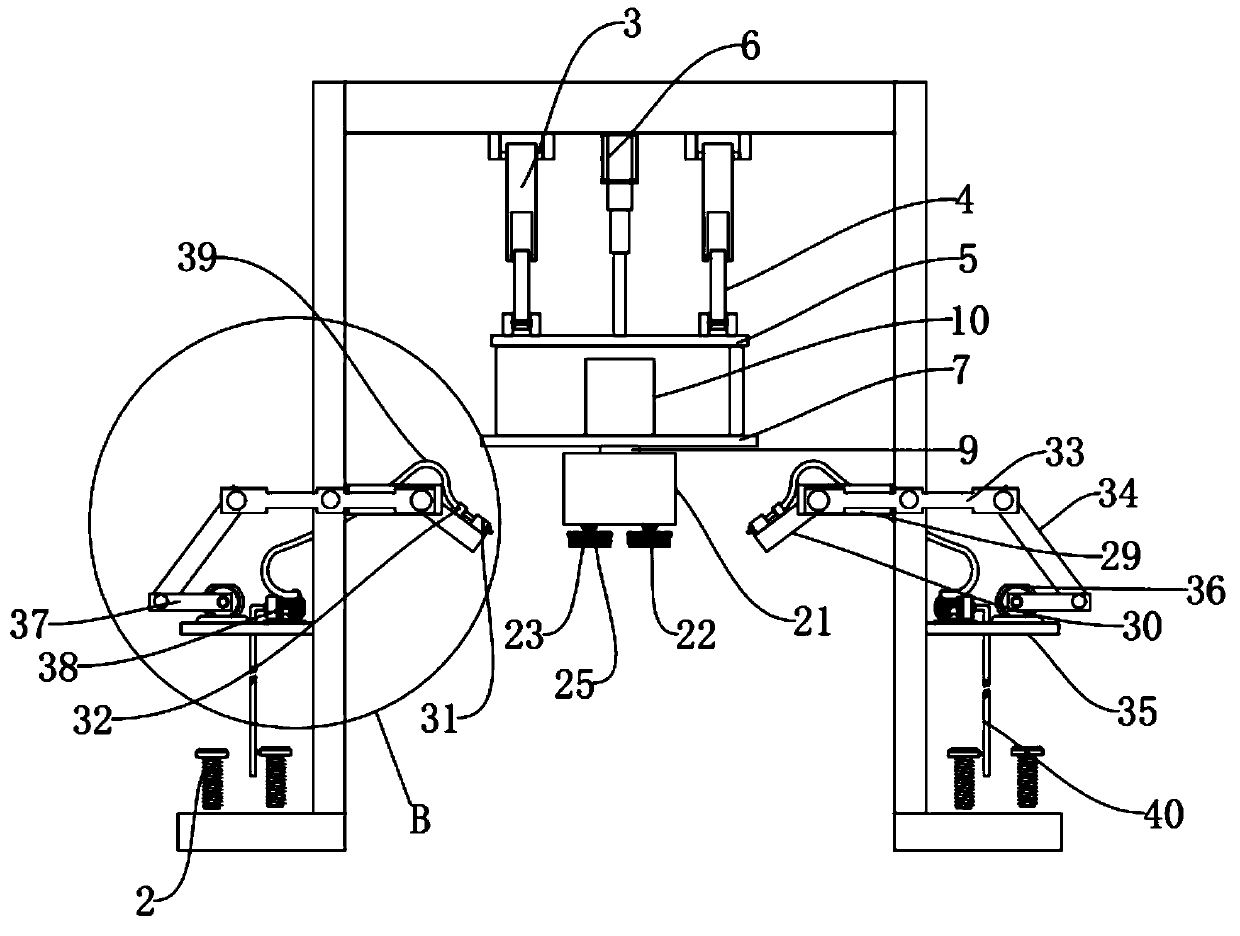

[0050] Embodiment: Attached by instruction manual Figure 1-5 It can be seen that firstly, after the equipment support 1 is fixed on the ground by screws 2, the equipment is powered on; after the vehicle to be cleaned is parked directly under the support 1, the hydraulic cylinder 6 is controlled to telescopically drive, and according to the height of the vehicle, after The flexible connection of the first elevating rod 3 and the second elevating rod 4 makes the carrying plate 5 lift and adjust the height, so that the wheel brush 25 contacts the roof; The water is introduced into the water pump 38, and made to enter the shunt pipe 32 through the water delivery pipe 39, and then enters into each nozzle 31 through the pipeline, and the vehicle body is sprayed and washed by the nozzle 31; The third motor 36 is driven to drive the rotating rod 37 to rotate passively, and then through the flexible connection of the connecting rod 34, the two ends of the swing rod 33 on the support 1 ar

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap