Porous nano fiber material, preparation method thereof and application of porous nano fiber material in monitoring nitrobenzene in chemical wastewater

A technology for nanofibers and chemical wastewater, applied in the fields of artificial filaments made of cellulose derivatives, fiber chemical characteristics, chemical post-treatment of cellulose/protein artificial filaments, etc., which can solve the problems of long preparation period, fluorescent agent leakage, Complicated synthesis steps and other issues, to achieve the effect of good universality, excellent regeneration performance, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Adopt the method described in the present invention to prepare porous nanofibrous material, comprise the steps:

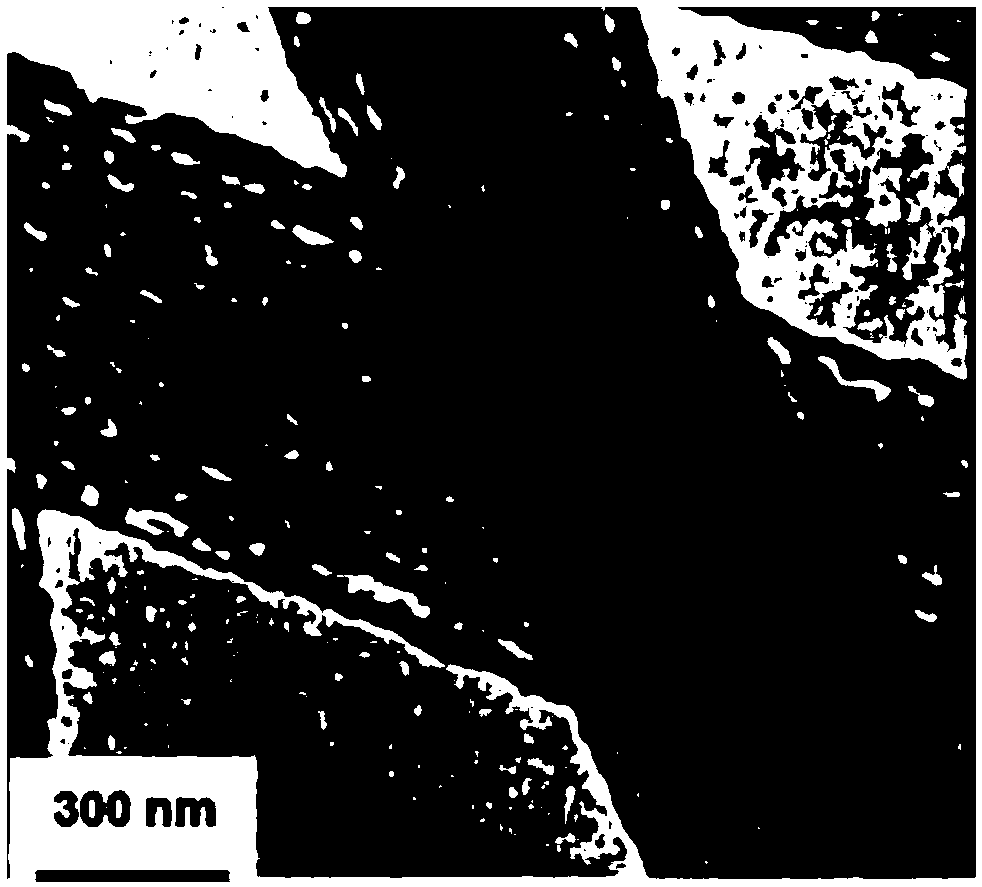

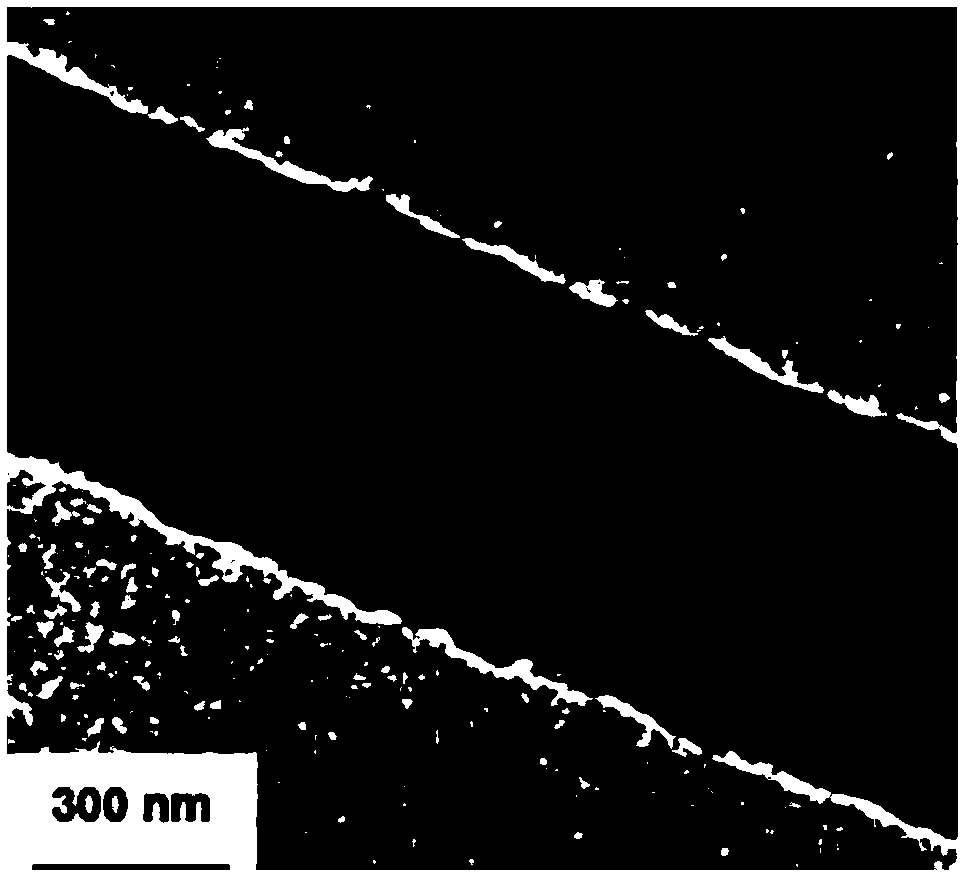

[0059] S1, at room temperature, 100 parts by weight of cellulose acetate, 8 parts by weight of 9-chloromethanethracene, 50 parts by weight of PEG-4000 and 700 parts by weight of N,N-dimethylacetamide and acetone in 1: The mixed solvent formed by the weight ratio of 2 was stirred for 30 minutes under the magnetic stirring at a speed of 300 rpm until the system was completely mixed evenly, and the electrospinning stock solution was prepared;

[0060] S2, put the electrospinning stock solution prepared above in the syringe of the electrospinning equipment, and spray the electrospinning stock solution onto the surface of the conductive glass substrate of the receiver under the conditions of room temperature, 15kV voltage, and a pushing speed of 1.0mL / h to rotate evenly Coating, wherein the distance between the needle of the syringe and the receiver is 15cm, the r

Embodiment 2

[0065] The preparation method is the same as in Example 1, except that the raw material ratio listed in Table 1 is adopted; the rotating speed in step S1 is 260rpm, and the stirring time is 35 hours; the voltage in step S2 is 20kV, and the pushing speed is 1.2mL / h, the receiver rotating speed is 600r / min, the electrospinning time is 9min, the drying temperature in step S3 is 68°C, and the drying time is 14 hours; the soaking time in step S4 is 30 hours, and the drying temperature is 75 ℃, drying time is 10 hours.

Embodiment 3

[0067] The preparation method is the same as in Example 1, except that the raw material ratio listed in Table 1 is adopted; the rotating speed in step S1 is 320rpm, and the stirring time is 25 hours; the voltage in step S2 is 15kV, and the pushing speed is 0.8mL / h, the receiver rotating speed is 500r / min, the electrospinning time is 10min, the drying temperature in step S3 is 70°C, and the drying time is 15 hours; the soaking time in step S4 is 40 hours, and the drying temperature is 80 ℃, drying time is 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap