Medical plug-in type baby carriage

A baby carriage, plug-in technology, applied in the direction of baby carriage/stroller, multi-axle baby carriage/cradle, baby carriage/cradle accessories, etc. To achieve the effect of convenient placement and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

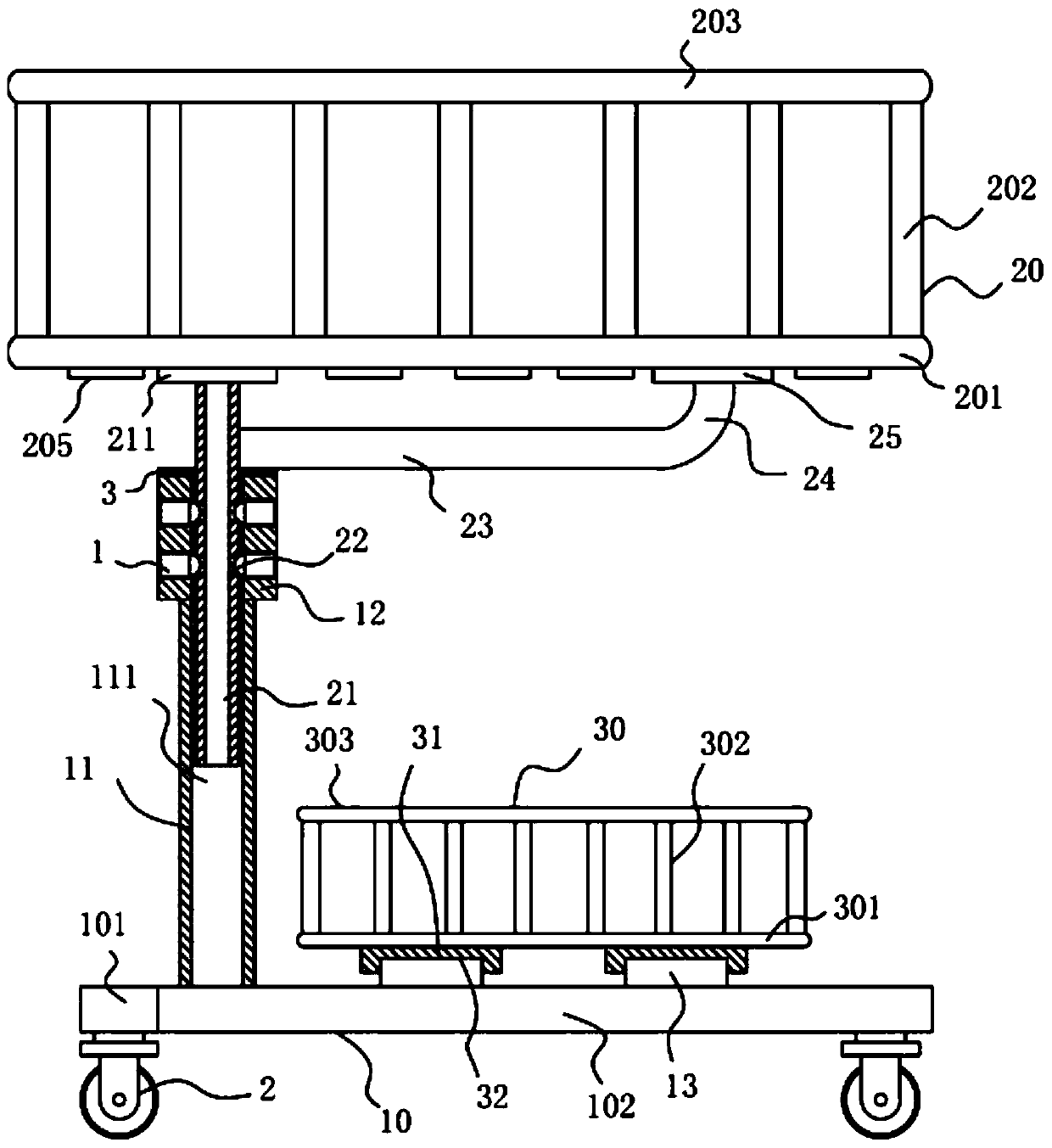

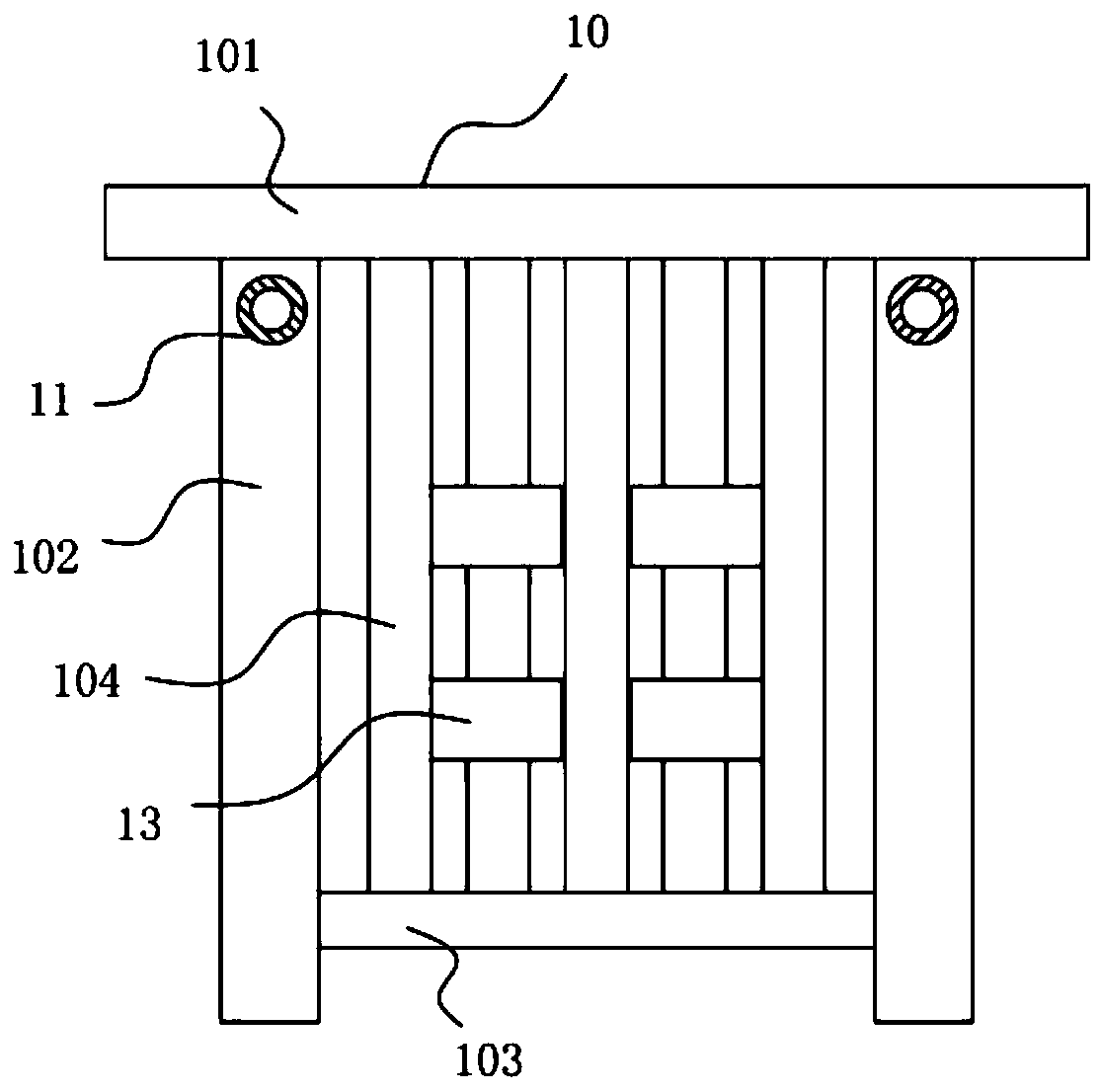

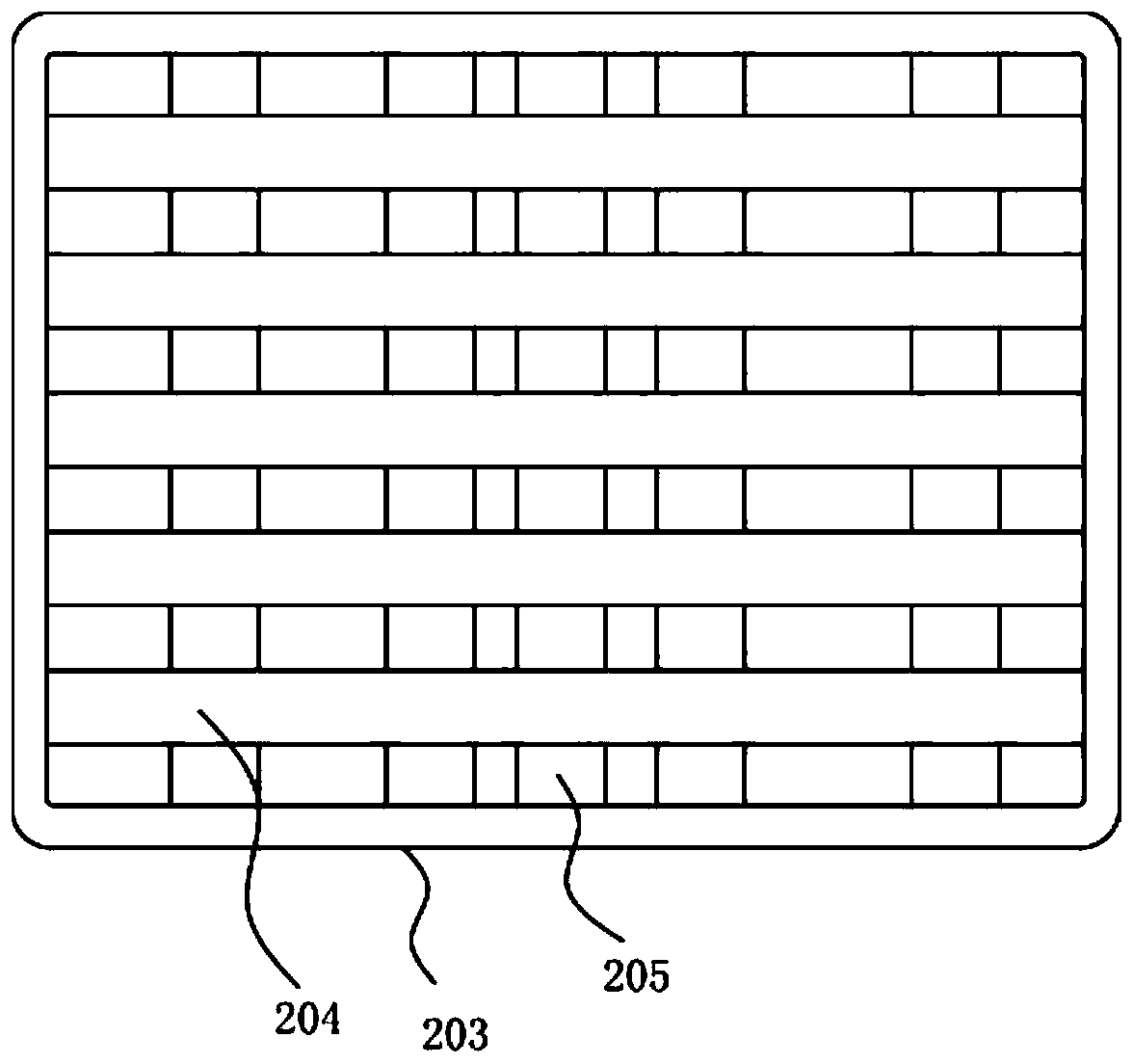

[0021] Example: see Figure 1 to Figure 4 As shown, a medical plug-in stroller includes a vehicle chassis 10, the front and rear of the top surface of the rear part of the vehicle chassis 10 are fixed with vertical support columns 11, and the vertical support columns 11 There is a vertical central through hole 111 in the middle of the vertical support column 11, and the top of the vertical support column 11 is fixed with an annular sleeve body 12. The baby placement basket 20 is above the two annular sleeve body 12, and the front and rear portions of the rear portion of the baby placement basket 20 The bottom surface of each is fixed with the main inserting rod 21, the main inserting rod 21 is inserted into the vertical center through hole 111 of the annular sleeve body 12 and the vertical support column 11, and the inner side wall of the annular sleeve body 12 is formed with a plurality of screw joints. A through hole, a plurality of ball plungers 1 are screwed in the threaded t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap