Actuator and wire fixing structure thereof

A technology for fixing structures and actuators, applied in the directions of electric components, casings/covers/supports, electrical components, etc., can solve the problems of loose or falling off of the covering sleeve, unfavorable assembly, wire damage, etc., to improve the use effect. , Simple structure, ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

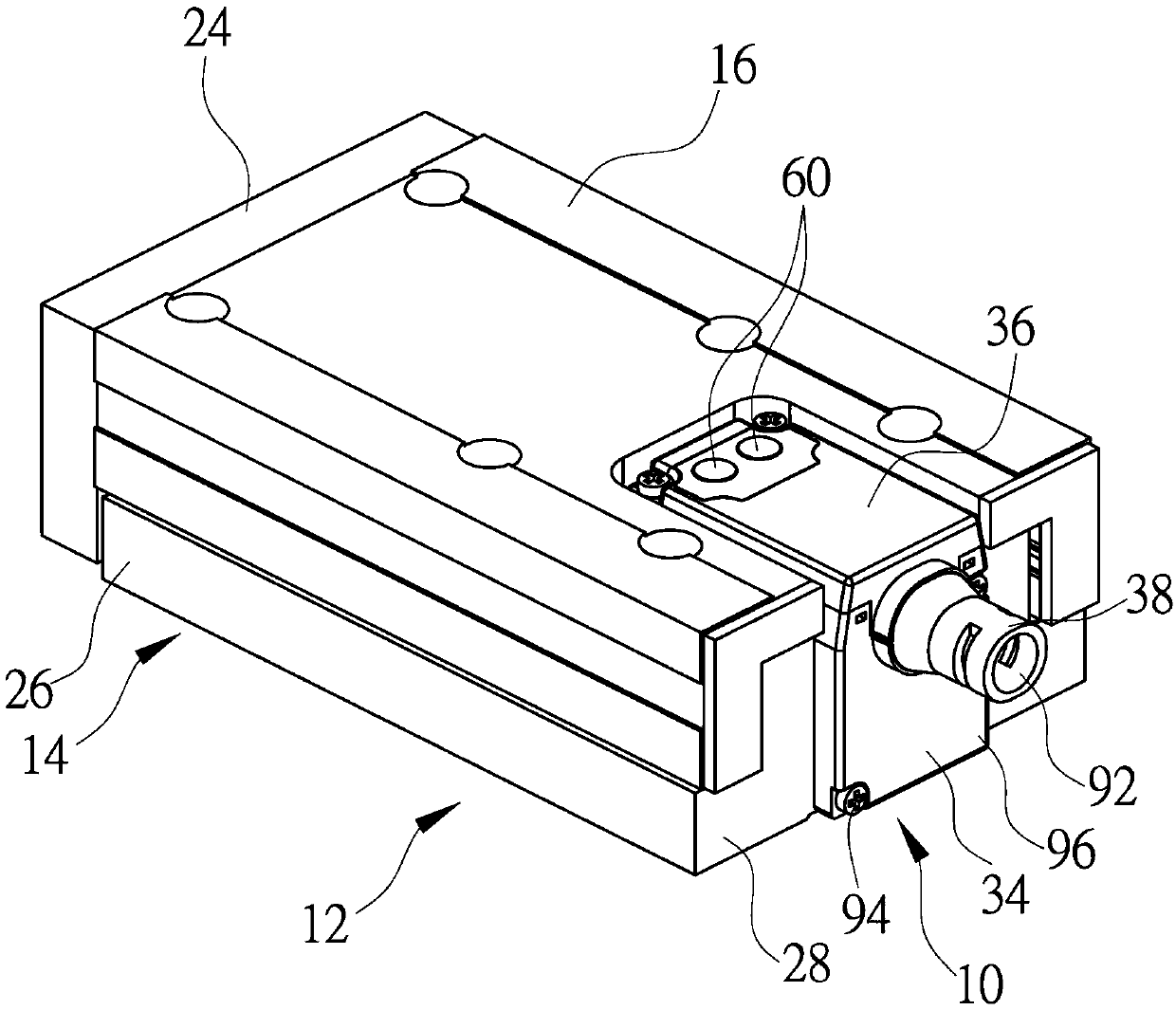

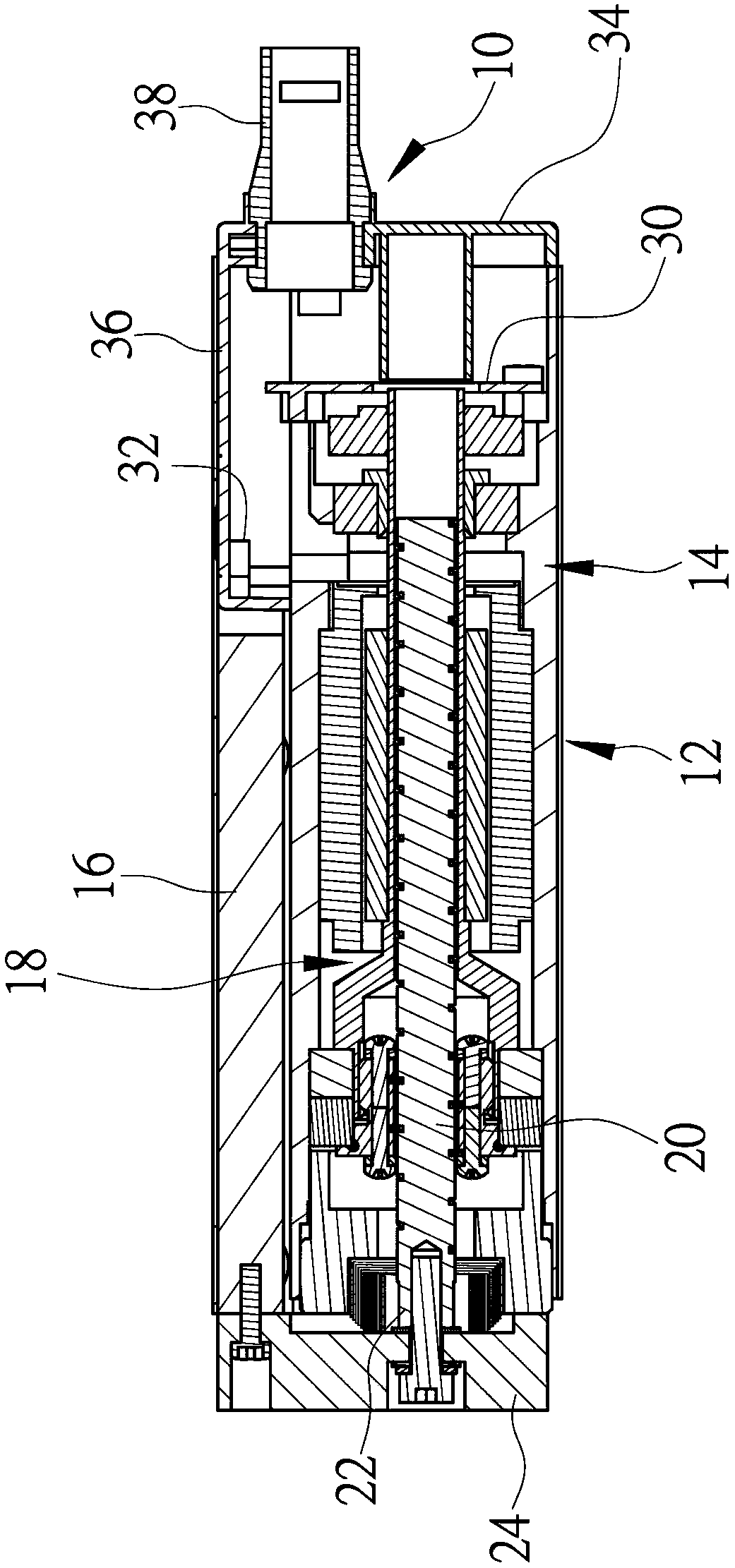

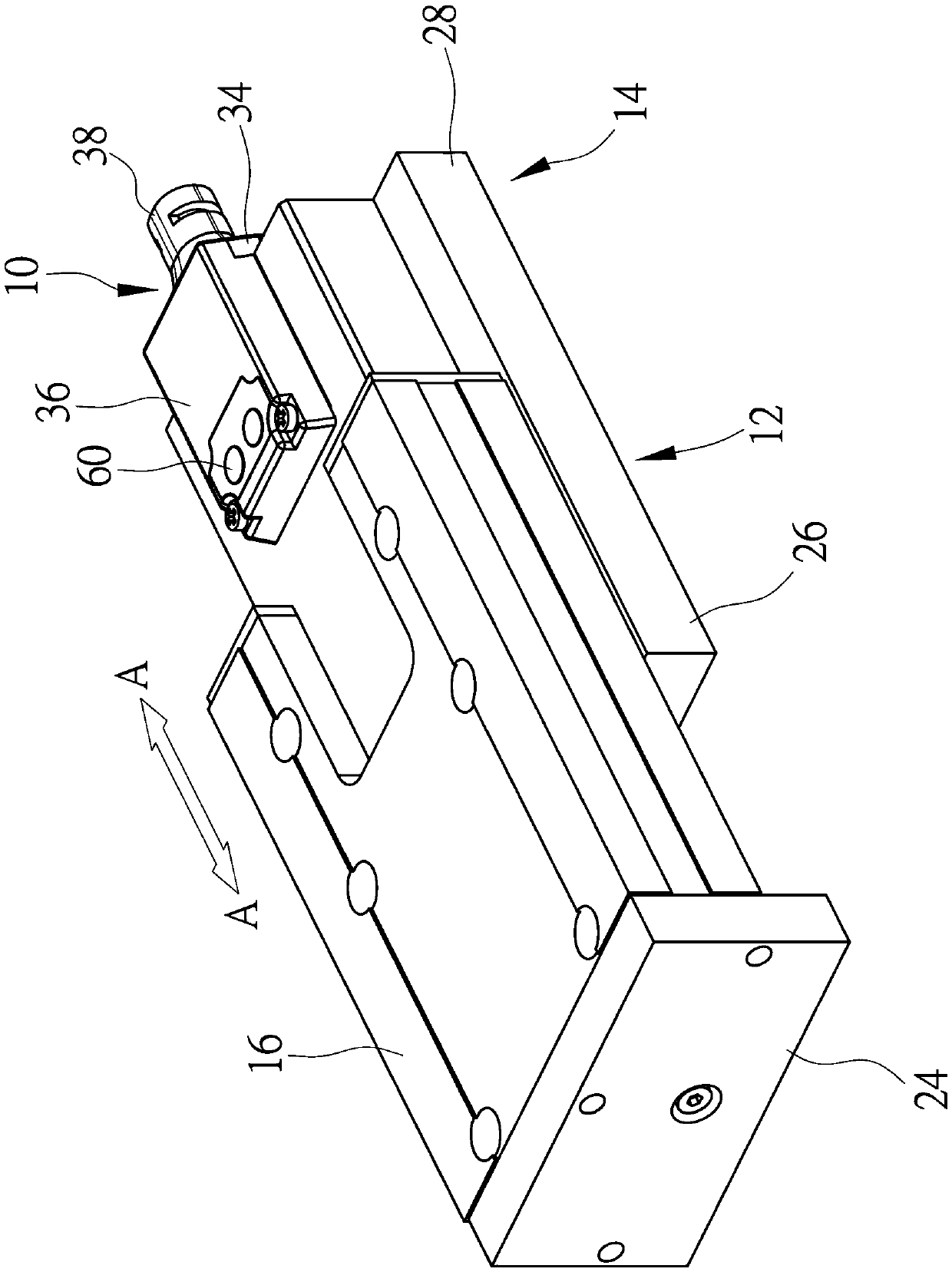

[0030] The present invention may have many different structural embodiments. Now it is only an example but not a specific embodiment for limitation, and with reference to the accompanying drawings, the preferred structural content of the present invention is described as follows:

[0031] Figure 1 to Figure 3 An embodiment in which the wire fixing structure 10 according to the present invention is applied to an actuator 12 is shown. In this embodiment, the actuator 12 is an electric cylinder and includes a main body 14 and a sliding seat 16 disposed on the main body 14 . A motor 18 and a screw 20 are arranged inside the main body 14 . The outer end 22 is combined with an output shaft fixing plate 24 , and the fixing plate 24 is combined with the sliding seat 16 . When the motor 18 is running, the screw 20 is driven to drive the fixing plate 24 and the sliding seat 16 along a longitudinal direction of the main body 14 (eg image 3 The direction indicated by the middle arrow A-

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap