Sludge concentration plant for water environment treatment

A technology for sludge concentration and water environment, applied in water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, sludge treatment, etc. The problems of high efficiency and sludge moisture content can reduce manpower input, improve efficiency and high concentration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

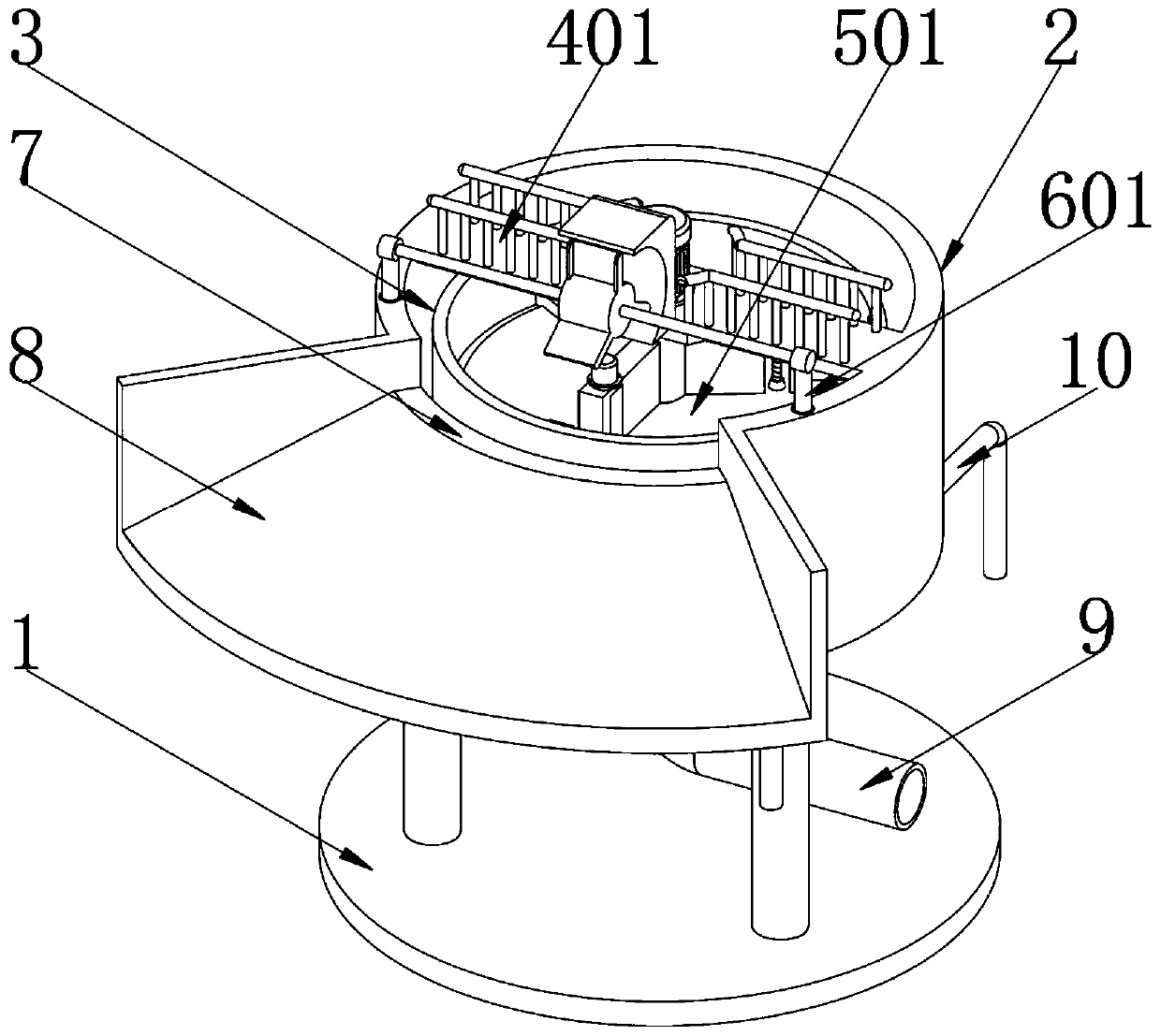

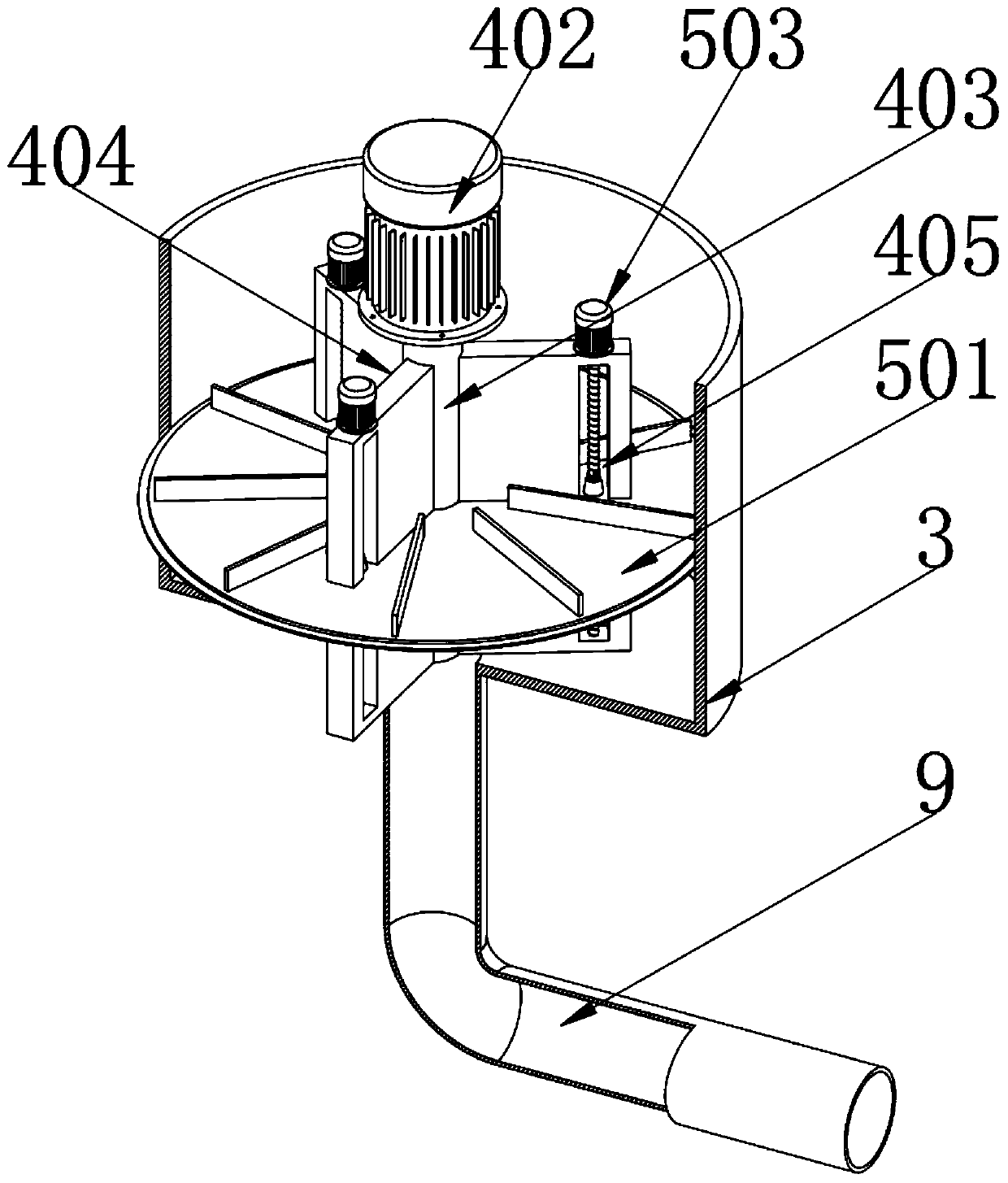

[0046] Example: such as Figure 1-6 As shown, a sludge concentration device for water environment treatment includes a support base 1, an outer tank body 2 and an inner tank body 3, an outer tank body 2 is fixedly installed above the support base 1, and an inner tank body 2 is fixedly installed inside the outer tank body 2. The tank body 3, the inner tank body 1 is equipped with a centrifugal component 4 for providing centrifugal force, which is used to provide centrifugal force for the muddy water inside the inner tank body 3, so that the sludge is separated from the water due to its high density and settles, completing the process of For the concentration of sludge, a lifting component 5 for lifting the sludge is installed on the outside of the centrifugal component 4, which is used to lift the concentrated sludge to the top of the inner tank 3, so as to facilitate the discharge of the concentrated sludge and avoid manual entry The inside of the inner tank body 3 processes the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap