Method for reducing hogging moment of composite beam at cable-stayed bridge auxiliary pier under action of live load

A technology of composite beams and auxiliary piers, which is applied in the direction of cable-stayed bridges, bridges, bridge parts, etc., can solve the problem of negative bending moment of composite beams, and achieve the effect of enhancing the flexibility characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

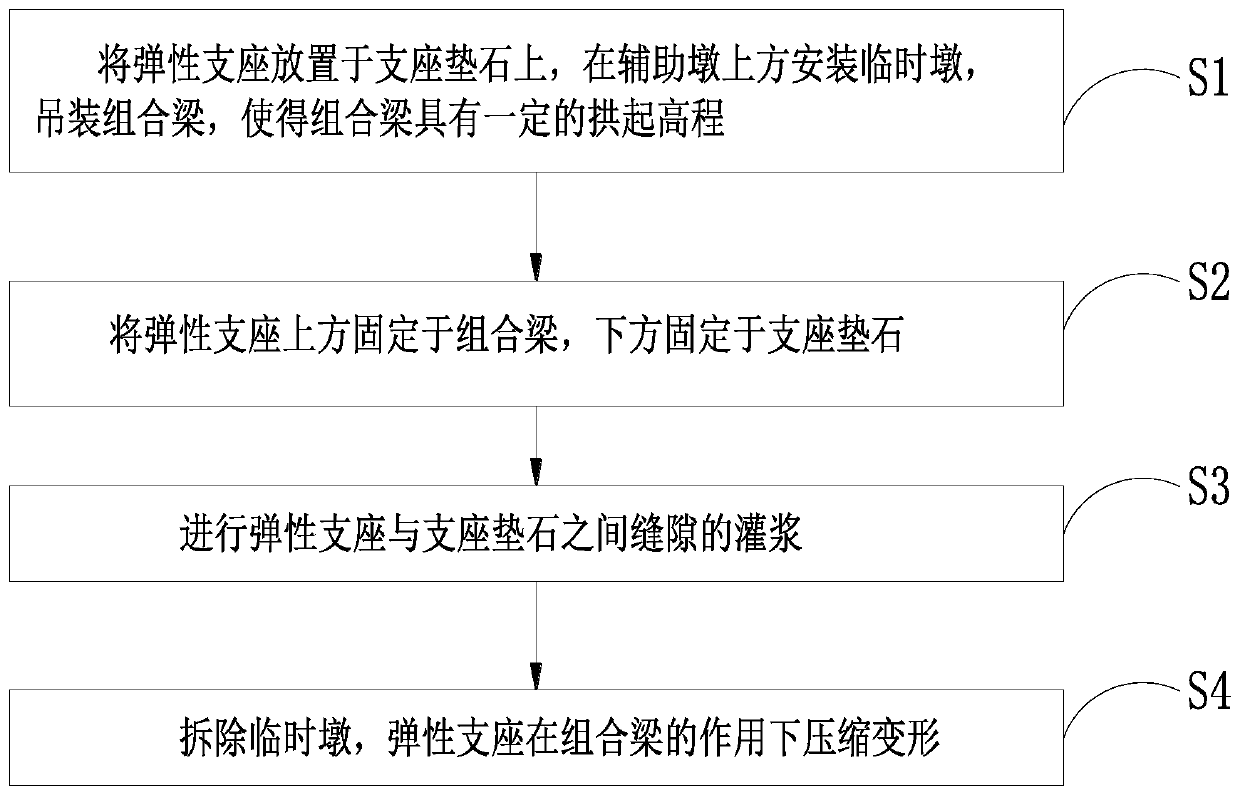

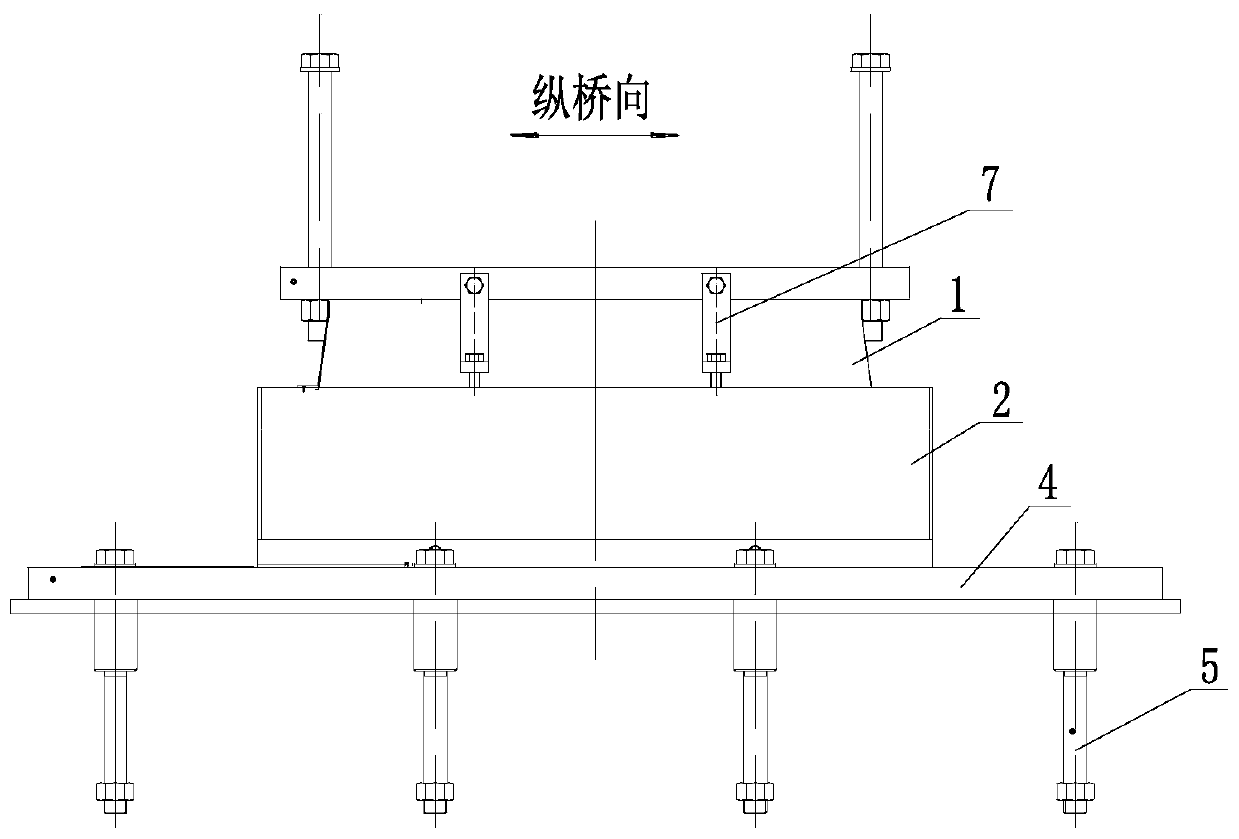

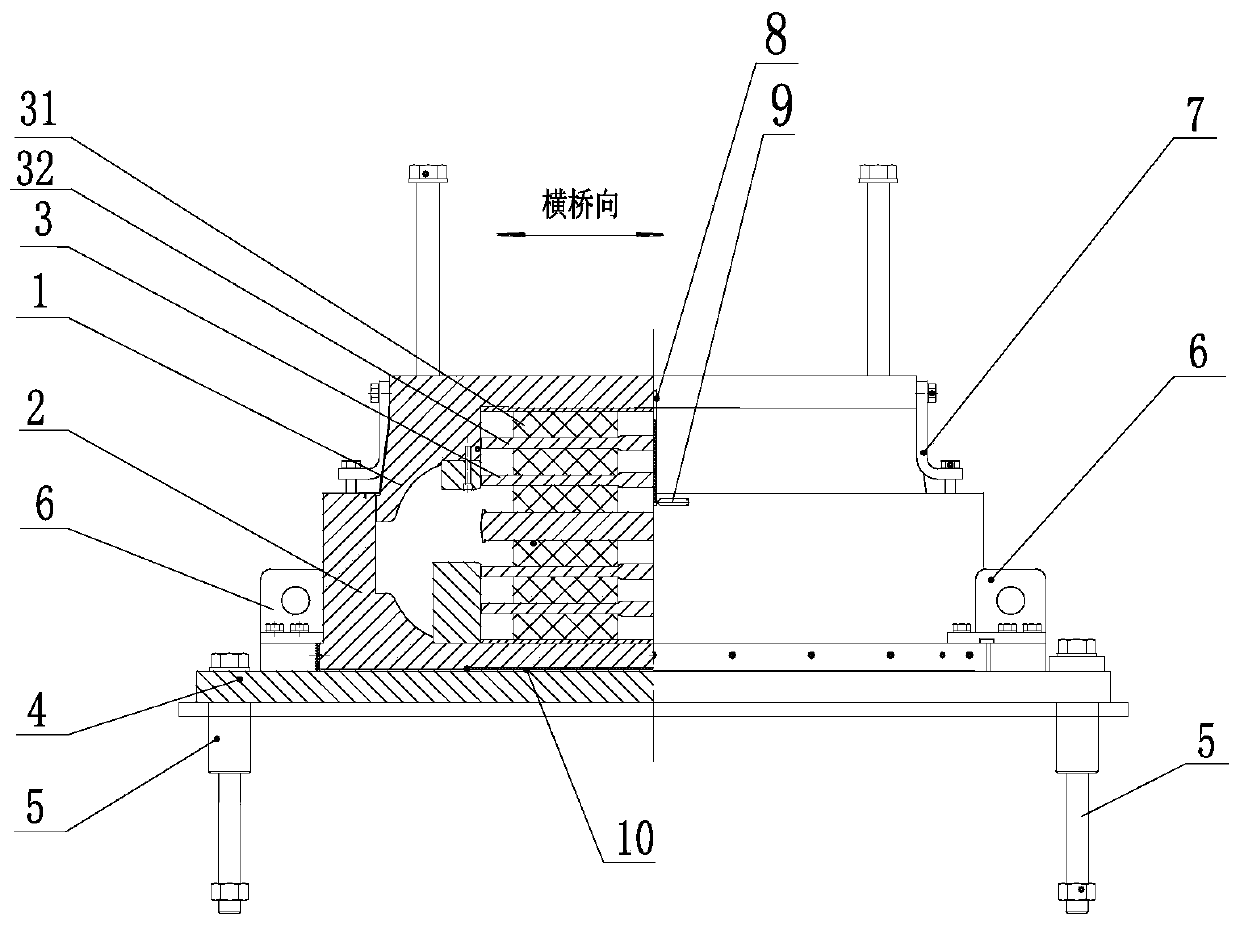

[0033] Such as figure 1 , Figure 5 and Figure 6 As shown, the invention discloses a method for reducing the negative bending moment of the composite beam at the auxiliary pier of a cable-stayed bridge under the action of live load, which reduces the negative bending moment of the composite beam at the auxiliary pier attachment under the action of live load, the method Contains the following steps:

[0034] S1: Place the elastic support on the support pad 22, install the temporary pier 14 above the auxiliary pier 21, and hoist the composite beam 20 so that the elevation of the composite beam 20 is H 0 +L 1 ; among them, H 0 Design elevation for the bridge; L 1 Arch the elevation for the composite beam 20.

[0035] S2: Fix the upper part of the elastic support to the composite beam 20 through bolts; fix the lower part of the elastic suppor

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap