Lightning arrester insulation performance testing device

A technology of insulation performance and test device, which is used in the construction of test ships and the test of dielectric strength, etc., can solve the problems of reduced insulation performance of arresters and the inability of arresters to be used safely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

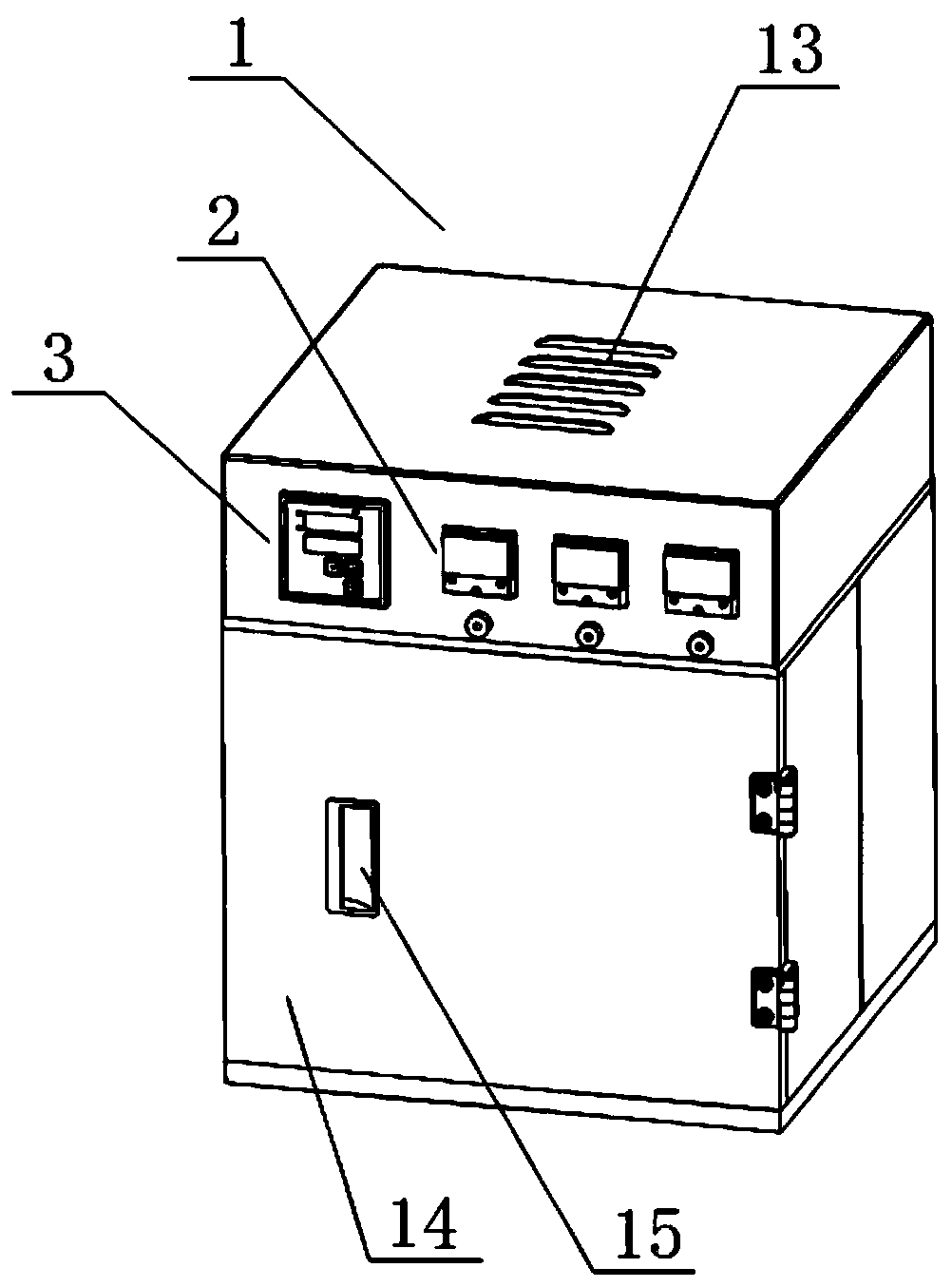

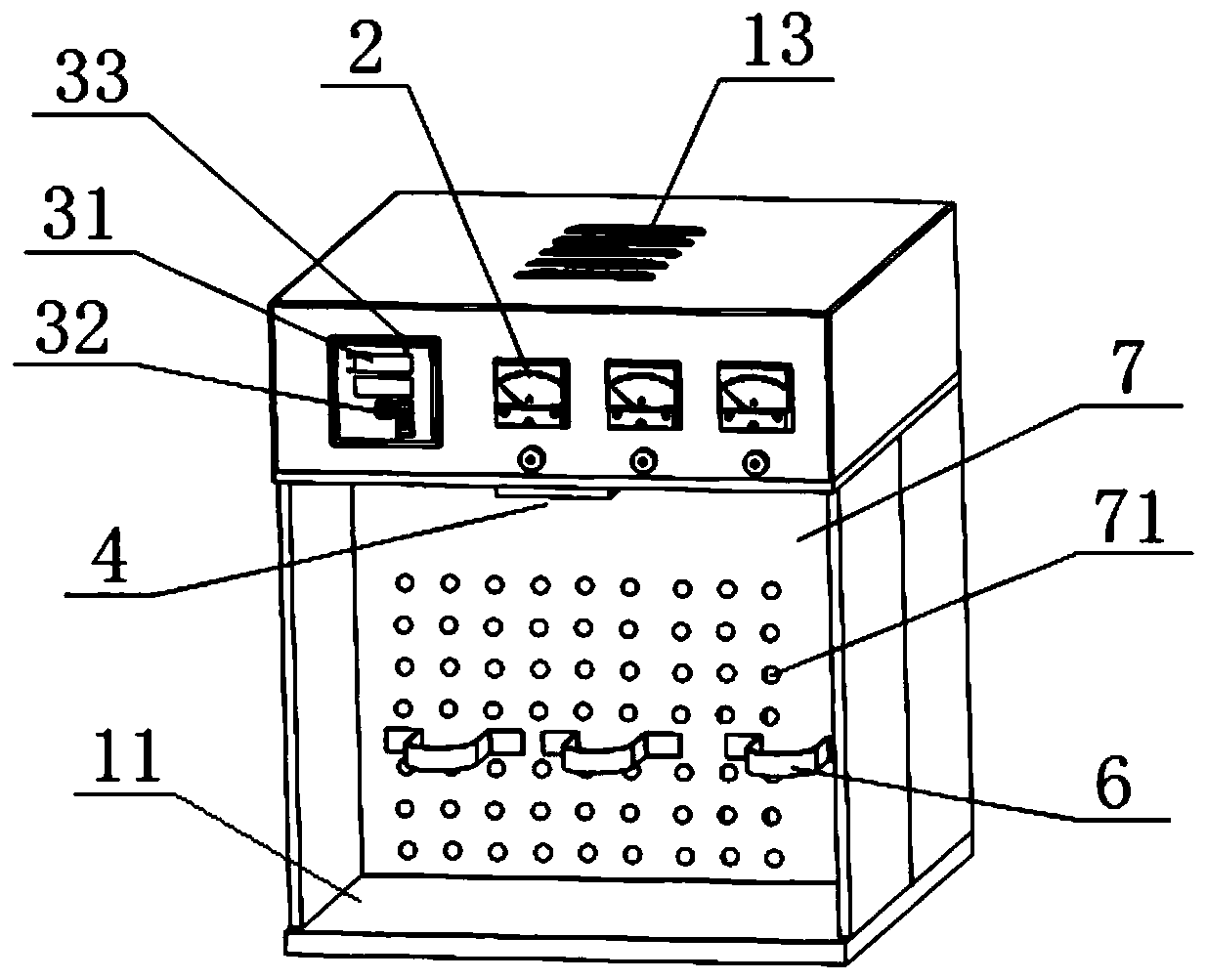

[0032] Such as figure 1 , figure 2 , Figure 4 to Figure 6 Shown is the first embodiment of a lightning arrester insulation performance test device of the present invention, including an oven 1, a measuring device 2 for electrical connection with the lightning arrester 8, and a temperature control device 3 and a temperature sensing device that are electrically connected in sequence 4. Heating device 5;

[0033] The heating device 5 is placed in the oven 1, so that the insulation performance test device can test the arrester 8 placed in the oven 1 by simulating the daily high temperature outdoors; It is transmitted to the temperature control device 3, and then the heating temperature and duration of the heating device 5 are controlled by the temperature control device 3, so as to prevent the temperature in the oven 1 from being too high and damage the arrester; the setting of the measuring device 2 can measure the insulation resistance value and DC resistance of the arrester.

Embodiment 2

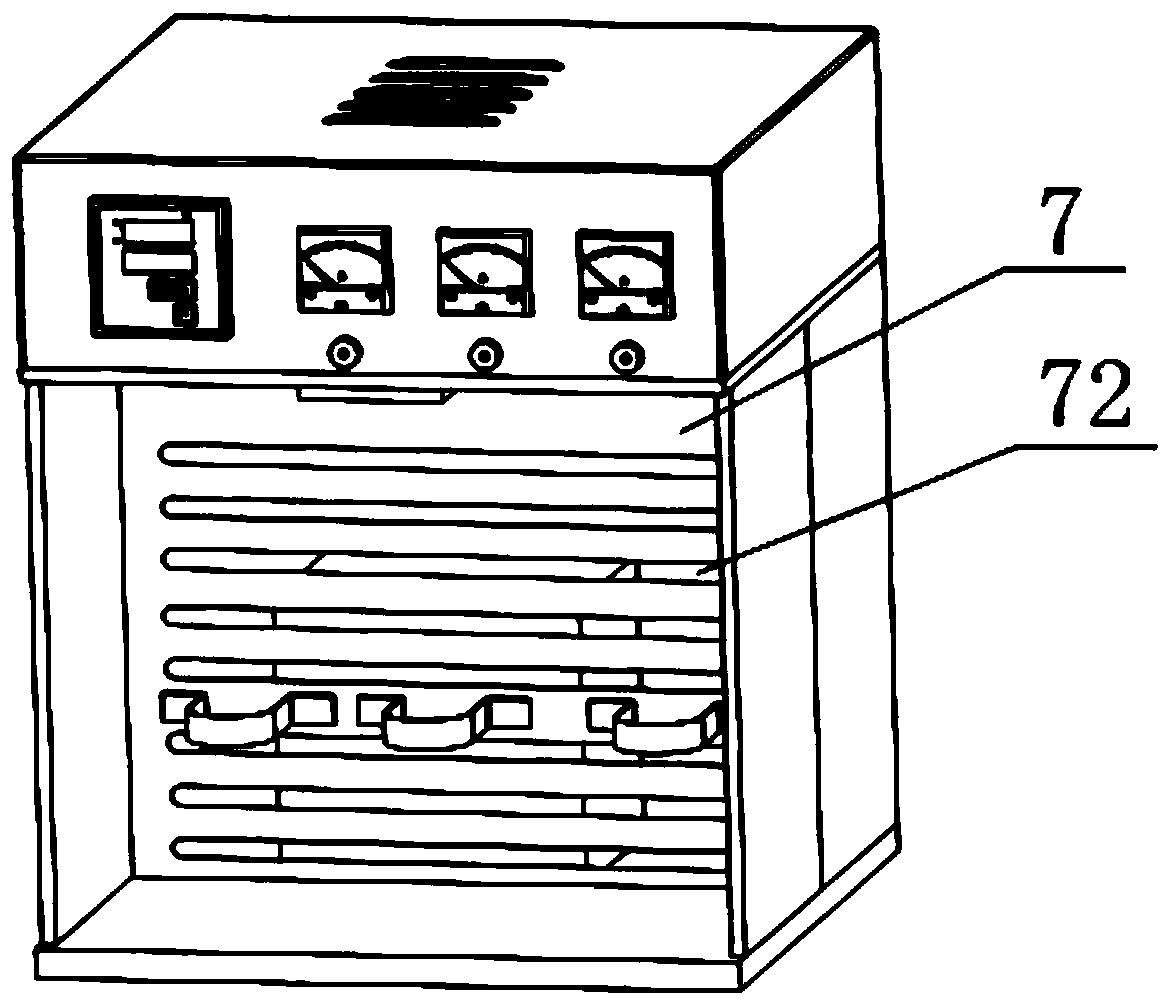

[0043] This embodiment is similar to Embodiment 1, except that the heat transfer plate 7 in this embodiment is provided with several slits 72 for heat transfer. The arrangement of the slit 72 enables the temperature inside the first accommodating cavity 11 to rise in an orderly manner. Such as image 3 As shown, the slit 72 is strip-shaped. It should be noted that the strip-shaped slits can be arranged horizontally, vertically, or obliquely.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap