Ultra-wideband four-ridge horn antenna capable of adjusting diameter of back cavity

A four-ridged horn, adjustable technology, applied in the field of communication, can solve the problem of large difference in performance of antenna feeding ports, and achieve the effect of good impedance matching and port consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

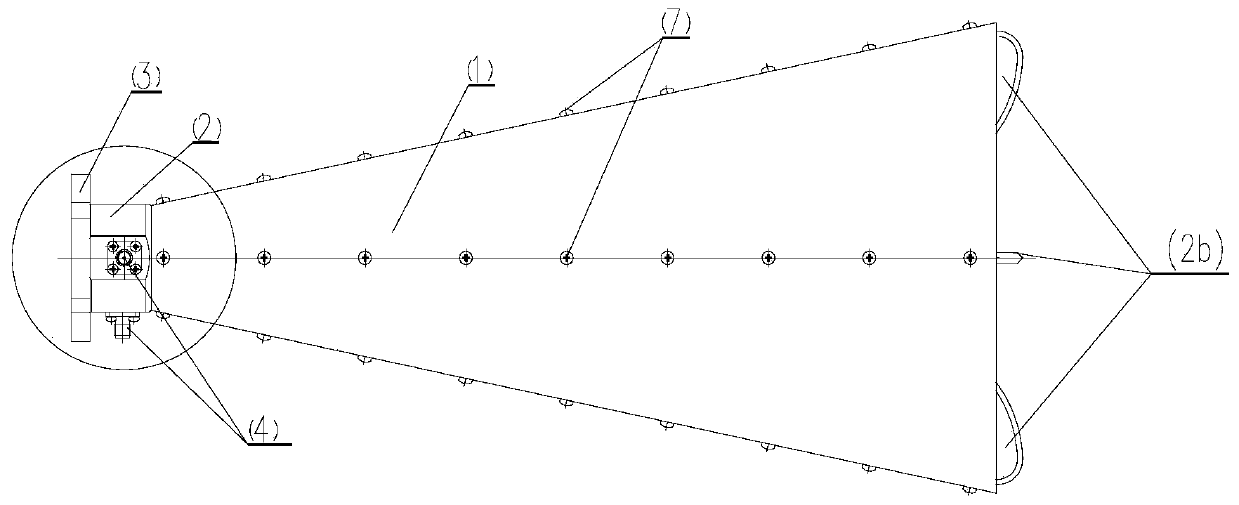

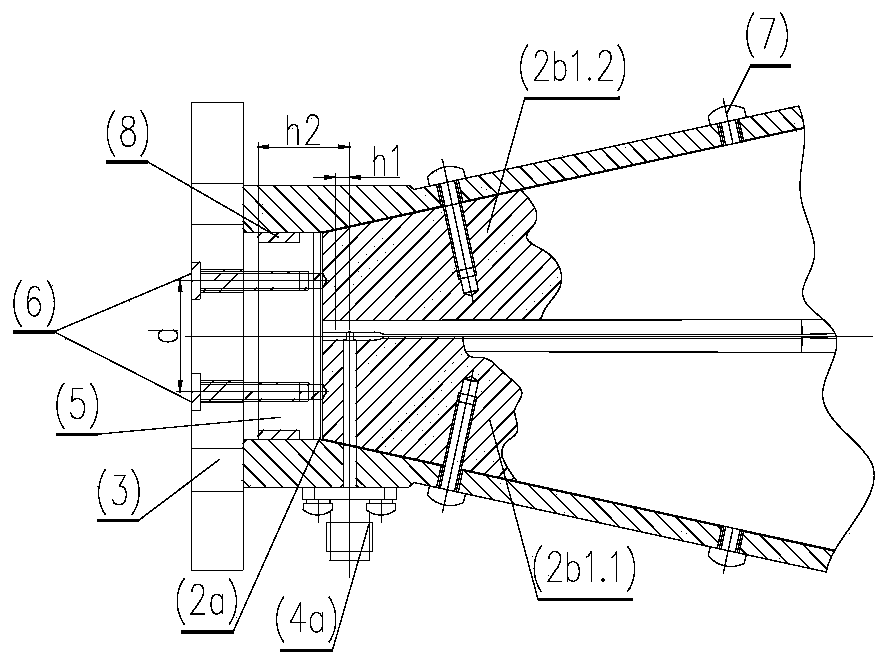

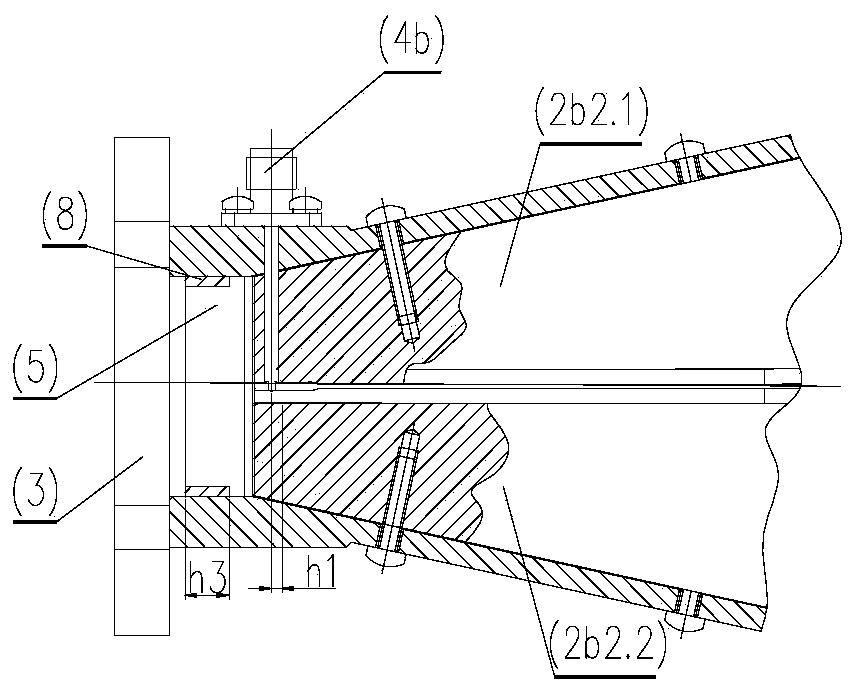

[0021] Such as Figure 1 ~ Figure 4 As shown, an ultra-wideband four-ridge horn antenna with an adjustable back cavity diameter includes a horn 1 (which can be a conical horn), a ridge waveguide 2, a reflective backplane 3, a radio frequency connector 4, and an adjustment screw 6; the ridge The waveguide 2 is connected to the reflective backplane 3, and the adjustment screw 6 penetrates the reflective backplane 3 and then extends into the back cavity 5 formed by the reflective backplane and the ridge waveguide, and short-circuits with the bottom ends of a pair of ridges in the excitation ridge waveguide 2;

[0022] The ridge waveguide 2 includes a waveguide 2a (which may be a circular waveguide) and four ridge

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap