Tobacco leaf redrying mechanical feeding system and feeding method

A technology of redrying tobacco leaves and tobacco leaves, which is applied in the direction of tobacco, prepared tobacco, conveyor objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

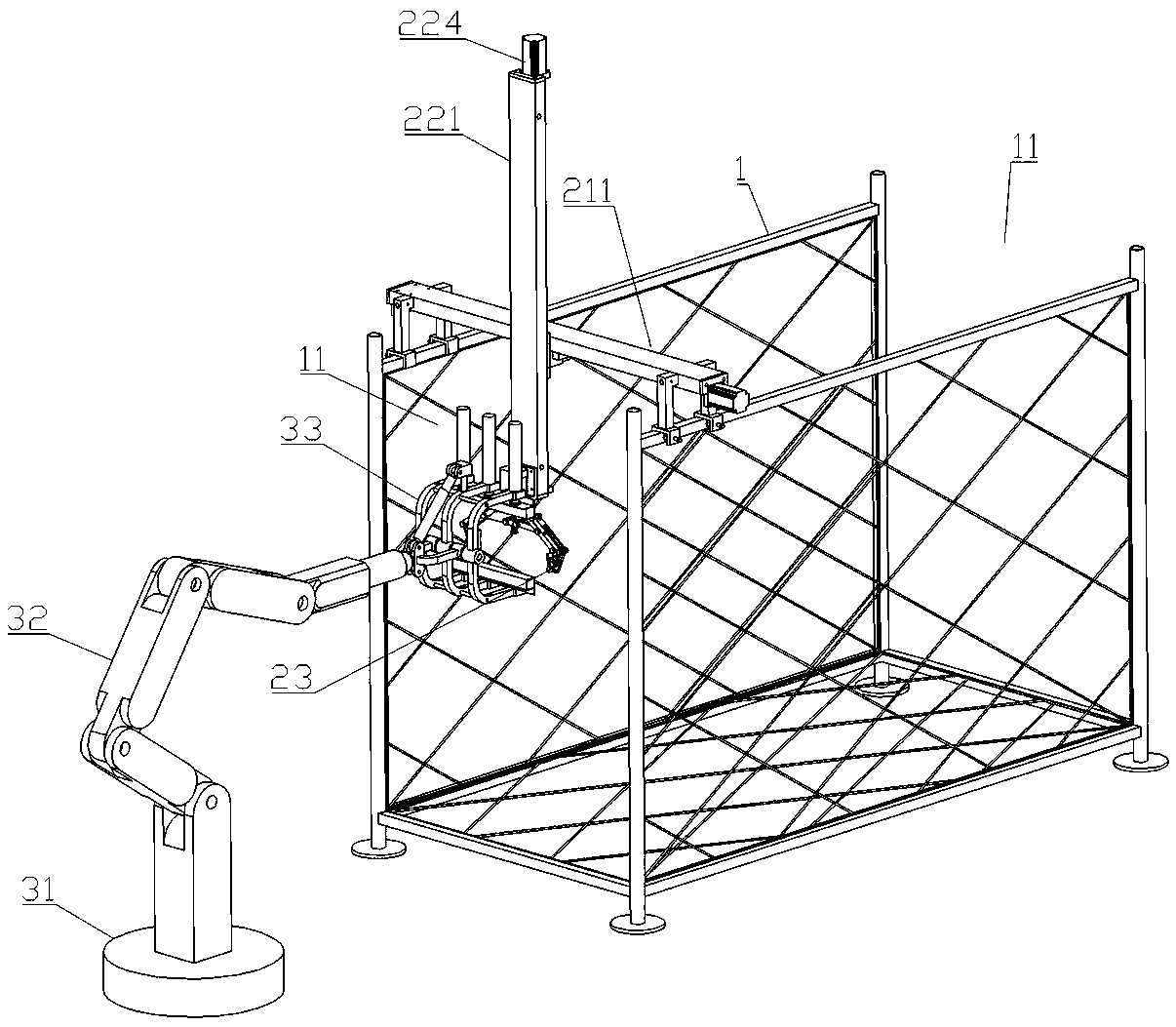

[0049] Such as Figure 1-4As shown, the tobacco re-curing mechanized feeding system includes a material frame 1, a tobacco leaf clamping device and a multi-axis robot.

[0050] One side wall or two opposite side walls of the material frame 1 are opened to form a filling port 11 .

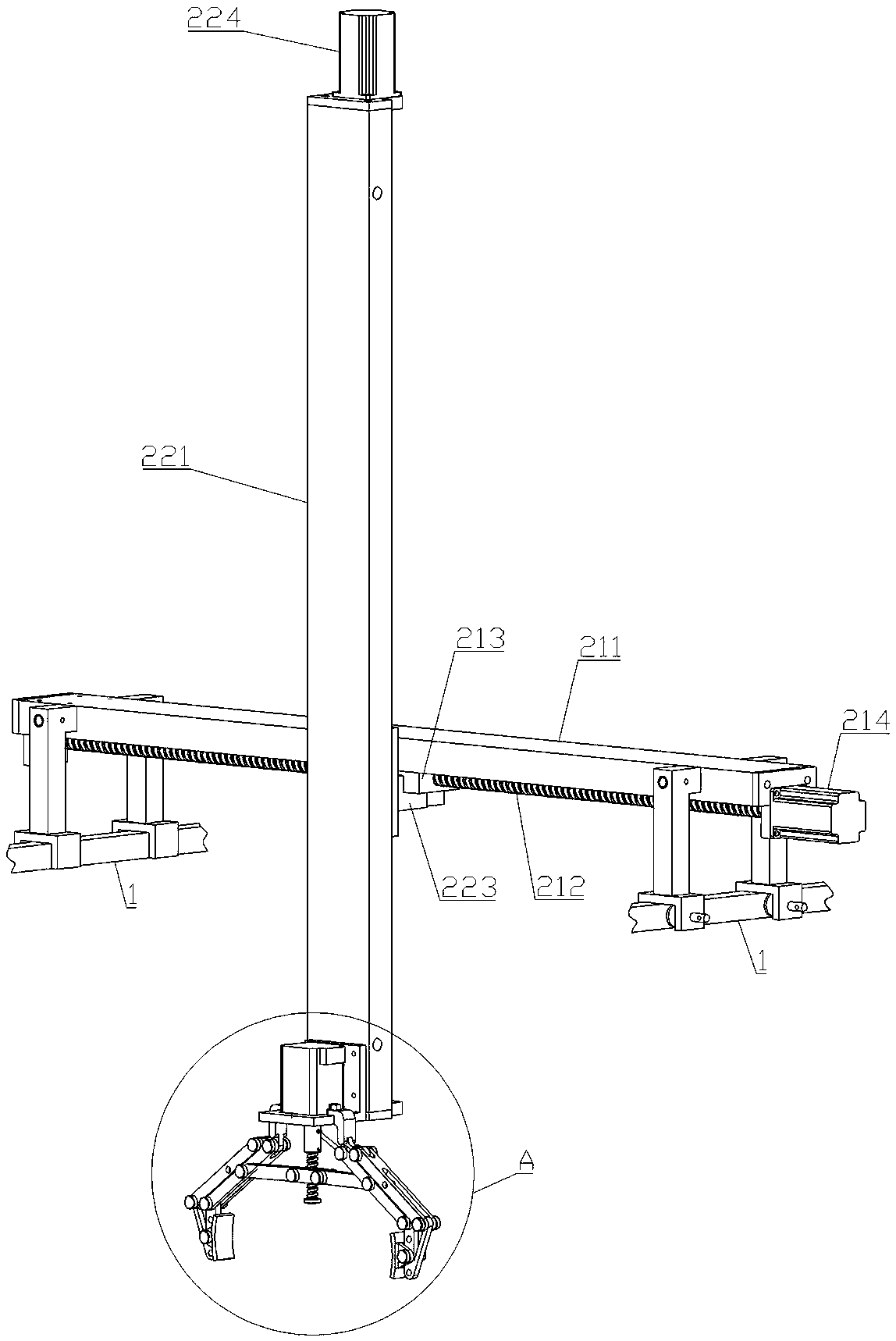

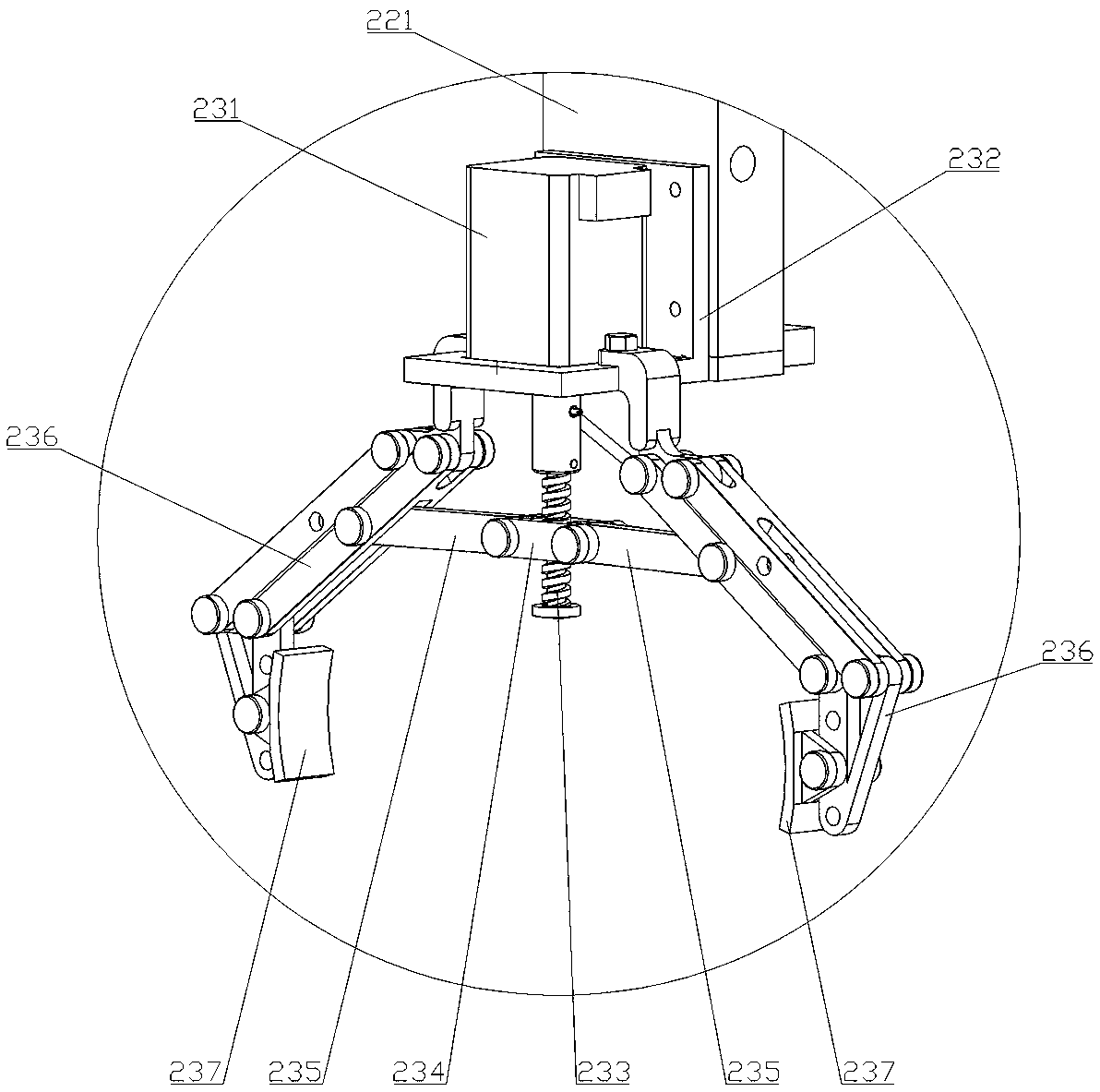

[0051] The tobacco leaf clamping and lifting device includes a lateral reciprocating mechanism, a vertical reciprocating mechanism and a separation claw 23 . The horizontal reciprocating movement mechanism is installed on the material frame and performs reciprocating movement in the horizontal direction. The vertical reciprocating mechanism is associated with the lateral reciprocating mechanism, and performs vertical reciprocating movement. The separation claw 23 is connected on the vertical reciprocating mechanism, and it moves in the plane where the filling port is located under the joint drive of the horizontal reciprocating mechanism and the vertical reciprocating mechanism.

[0052] The lateral

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap