Self-adjusting steel coil fixing flatcar

A self-adjusting, steel coil technology, applied in trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of inconvenient production and use, inability to fix steel coils, hidden dangers of steel coils, etc., to ensure stability, ensure safety, Anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

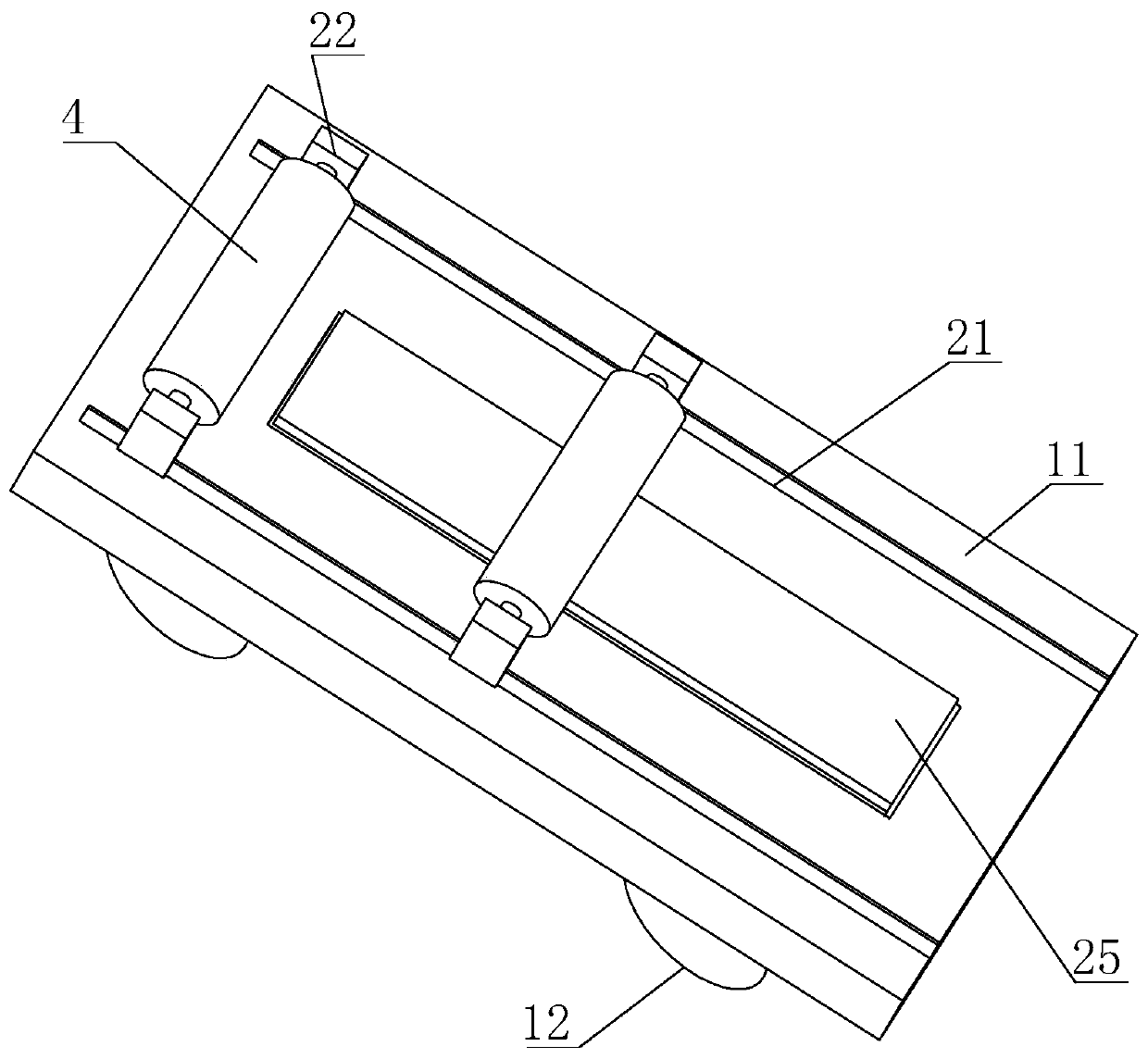

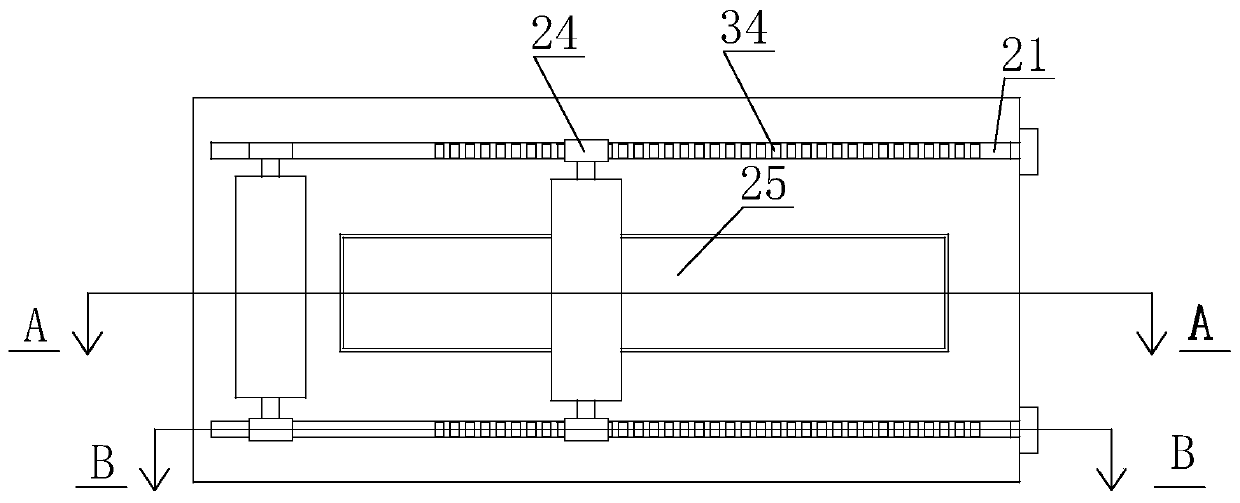

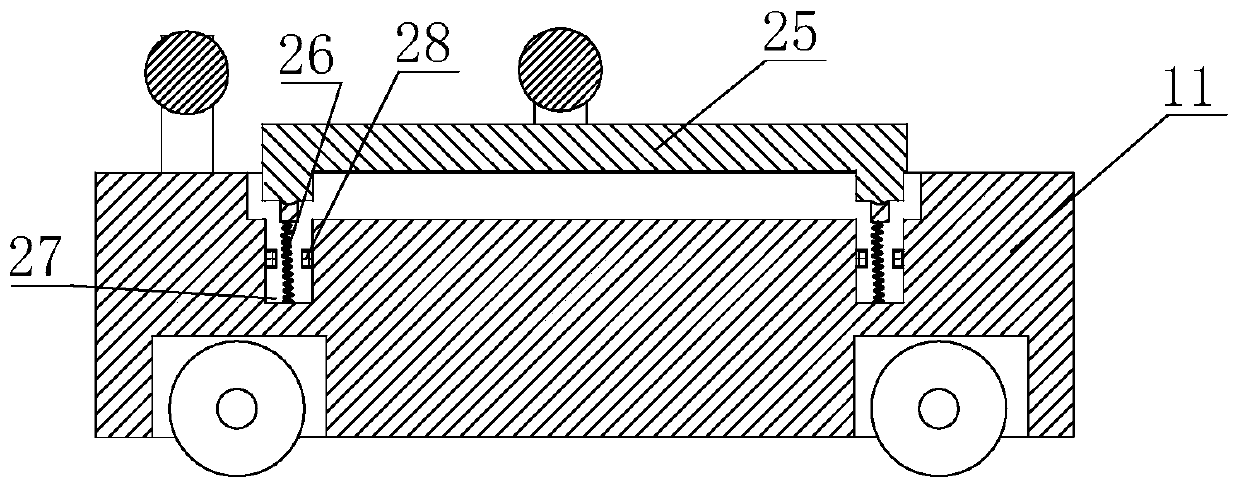

[0028] A self-adjusting steel coil fixed flat car, comprising a car body 11, the lower part of the car body 11 is provided with wheels 12, the upper surface of the car body 11 is provided with a slide rail 21 and a first limit frame 22, and the slide rail 21 is two, the first limit frame 22 is fixedly connected with the car body 11, the slide rail 21 is provided with a slider 23, the slider 23 is slidingly connected with the slide rail 21, and the upper part of the slider 23 A second limit frame 24 is provided, and the upper part of the vehicle body 11 is provided with a bearing plate 25, the bearing plate 25 is located in the middle of the vehicle body 11, the lower part of the bearing plate 25 is provided with a first spring 26, and the first spring 26 is located inside the vehicle body 11, the lower part of the first spring 26 is fixedly connected with the vehicle body 11, and the inside of the vehicle body 11 is provided with a vertical pipe 27, the first spring 26 is locat...

Embodiment 2

[0032] A self-adjusting steel coil fixed flat car. On the basis of Embodiment 1, in order to further ensure the safety of the steel coil during transportation, the side wall of the car body 11 is provided with a through hole 51, and the through hole 51 It communicates with the side wall of the slide rail 21, the through hole 51 is provided with a positioning rod 52, when the controller 29 or the electric cylinder 31 has a problem or an unexpected situation occurs, the positioning rod 52 is inserted to the position of the slider 23 In the corresponding through hole 51, the positioning rod 52 can form a position for the slider 23, which can further ensure the safety of the steel coil during transportation.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap