Sewage treatment device

A technology of sewage treatment device and driving device, which is applied in the fields of water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Ease of setup, reduced footprint, increased applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

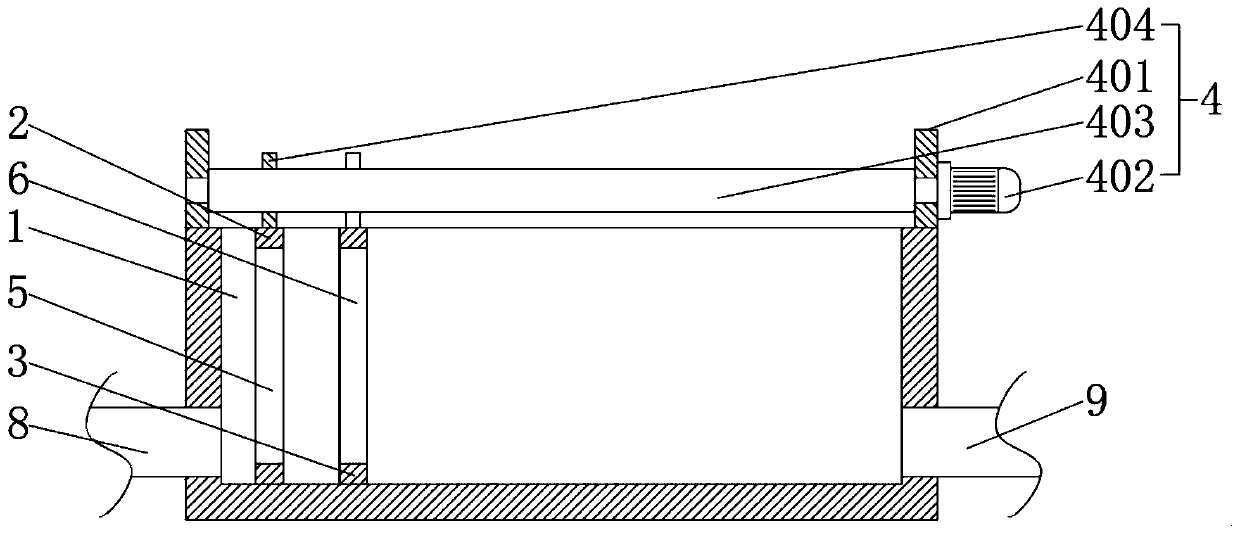

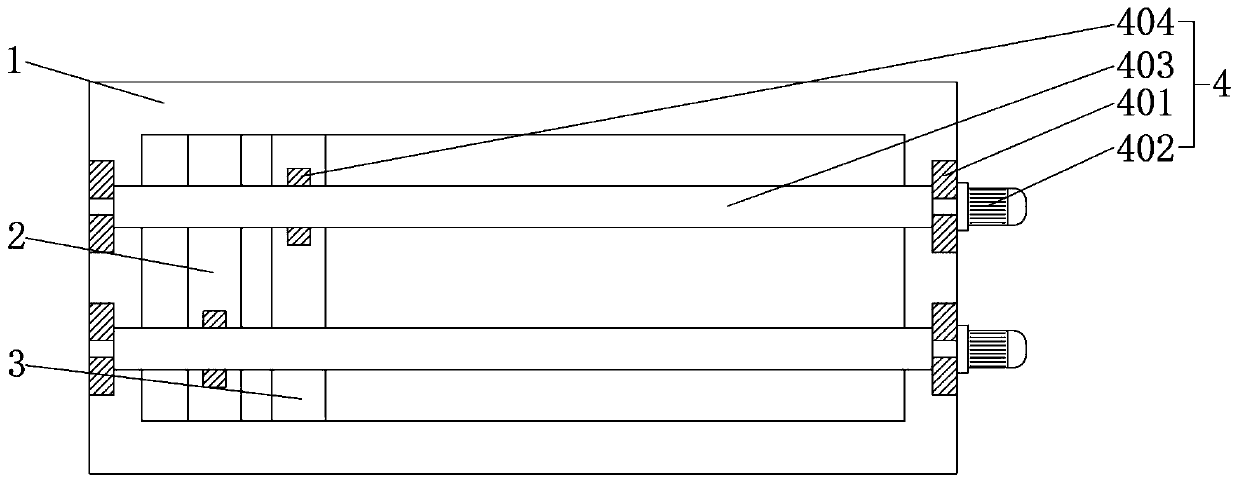

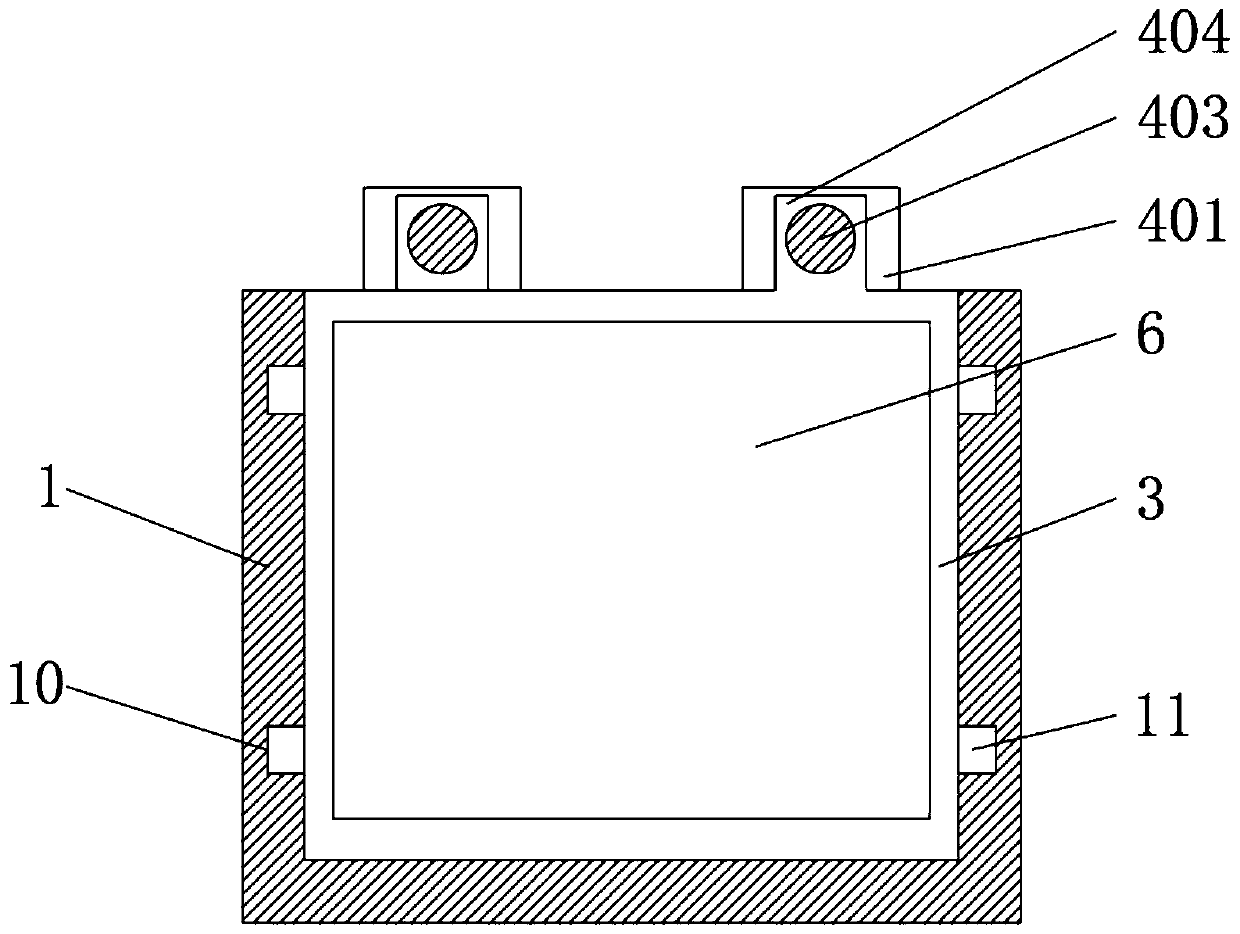

[0025] see Figure 1-3 , the present invention provides a technical solution: a sewage treatment device, comprising a reservoir 1, such as figure 1 As shown, the storage tank 1 is rectangular, and the storage tank 1 of different shapes can also be replaced according to actual needs. The storage tank 1 can be arranged below the ground, so as to save space and facilitate viewing of the storage tank 1 The inner side of the reservoir 1 is respectively provided with a first partition 2 and a second partition 3 that can slide along the extending direction of the reservoir 1, such as image 3 As shown, the size of the first partition 2 and the second partition 3 is the same as the size of the internal chamber section of the reservoir 1, so as to ensure that the first partition 2 and the second partition The outer surfaces of 3 can be in close contact with the inner side walls of the reservoir 1, so that the sewage in the reservoir 1 cannot be separated from the first partition 2 and th

Embodiment 2

[0030] see Figure 4-5 , the difference between this embodiment and embodiment 1 is: as Figure 5 As shown, the end surfaces of the first partition 2 and the second partition 3 are respectively provided with a plurality of through holes 7, and the filter grid 5 and the biofilm layer 6 are respectively arranged in the through holes. 7, so that the first partition 2 and the second partition 3 have good strength, the sewage flows in through the through hole 7, thereby being carried out by the filter grid 5 and the biofilm layer 6 deal with.

[0031] Specifically, the driving device 4 includes a hydraulic push rod 405, the storage tank 1 is close to the side wall of the filter grid 5 and between the filter grid 5 and the storage tank 1 is close to the Hydraulic push rods 405 are respectively provided between the side wall of the biofilm layer 6 and the biofilm layer 6, because the biofilm layer 6 and the filter grid 5 are arranged on the first through the through hole 7. On the pa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap