Pressure vessel detection equipment and method thereof

A pressure vessel and detection equipment technology, applied in the field of pressure vessel manufacturing, can solve the problems of affecting the detection accuracy, large volume of pressure vessels, high risk, etc., and achieve the effect of convenient operation, high safety and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

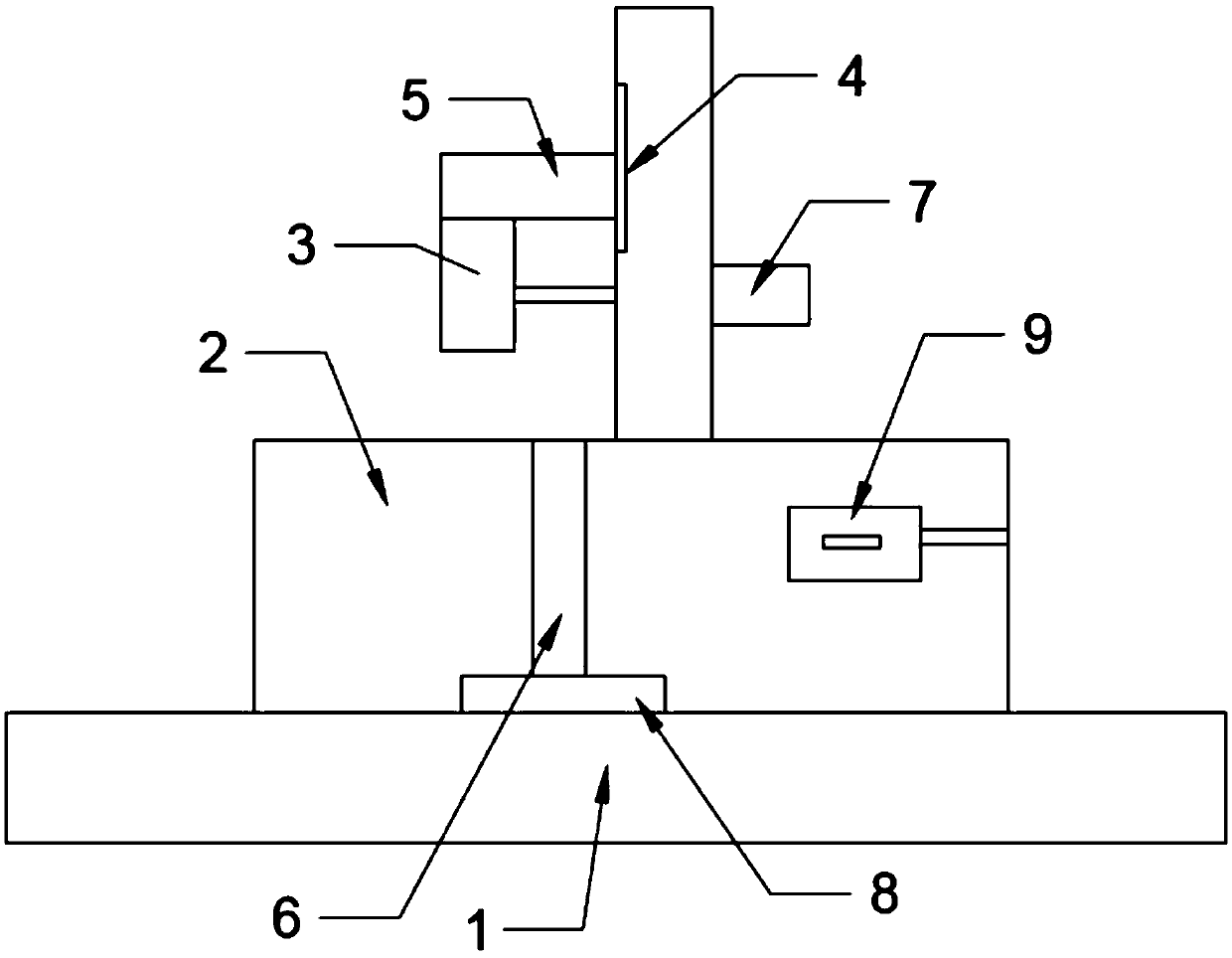

[0016] see figure 1 As shown, a pressure vessel testing device includes a frame 1, on which a conveying line 2 is arranged, and the conveying line 2 includes a horizontal conveying platform and a vertical conveying platform; a horizontal conveying guide rail is arranged on the horizontal conveying platform, and a Slidingly install the horizontal slider; the horizontal slider is provided with a first positioning groove that matches the outer contour of the container to be detected;

[0017] A vertical conveying guide rail is set on the vertical conveying platform; a vertical slider is slidably installed on the vertical conveying guide rail; a second positioning groove matching the outer contour of the container to be detected is arranged on the vertical slider; the horizontal slider and the vertical slider The conveying direction is vertical; one end of the horizontal conveying guide rail is connected with one end of the vertical conveying guide rail;

[0018] A turning mechanism

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap