Transportation and installation bracket for assembled construction component and construction method thereof

A mounting bracket and assembly-type technology, which is applied in hoisting devices, building structures, portable lifting devices, etc., can solve problems such as hindering construction efficiency and tower crane occupancy length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

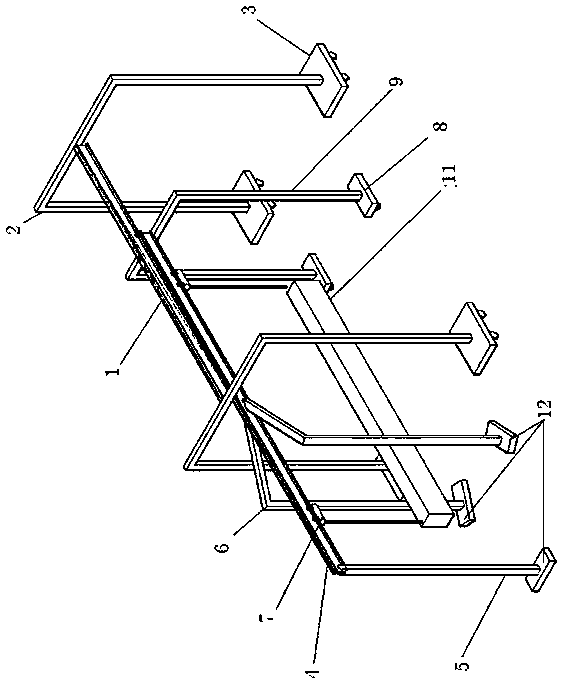

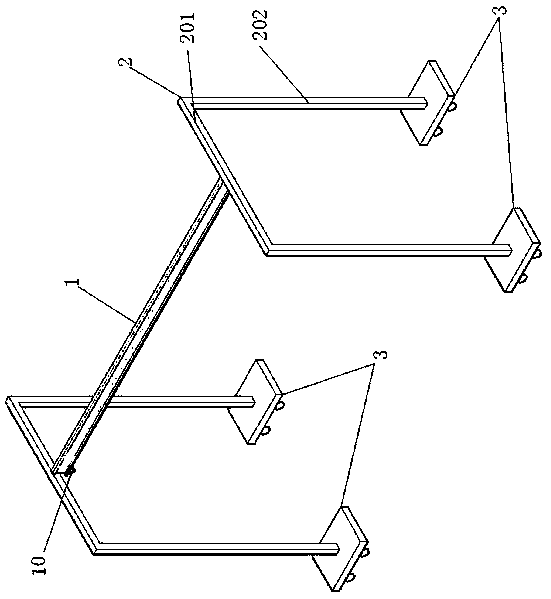

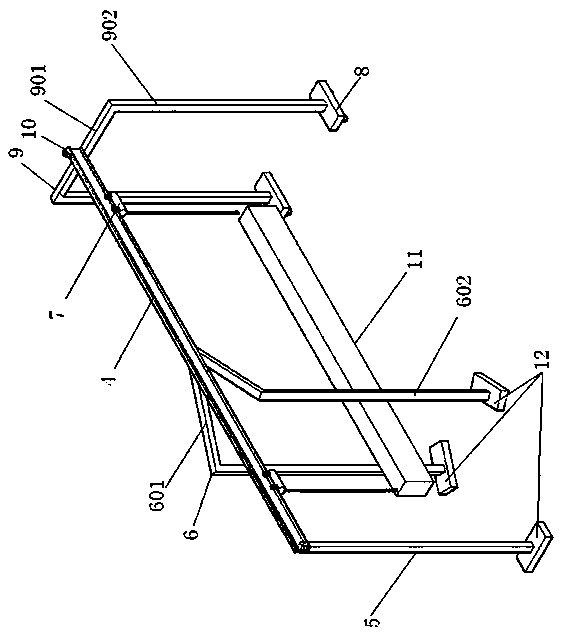

[0031] A transport and installation bracket for assembled construction components, including a bracket body, the bracket body is composed of an outer frame and an inner frame, the outer frame is composed of side brackets 2 and a central beam-1, and the left and right ends of the central beam-1 are welded There is a side bracket 2, and each side bracket 2 is a "door"-shaped structure welded by two uprights-202 and a cross-bar-201 respectively, the middle part of the cross-bar-201 is fixedly welded with the central cross-beam-1, and the upright The bottom of -202 is fixedly welded with the base of the mobile trolley -3. The bottom of the base of the mobile trolley -3 is equipped with four universal wheels, and the outer frame as a whole can be moved by the base of the mobile trolley -3.

[0032] The left end of the central beam two 4 of the inner fr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap