High-temperature three-dimensional digital image related measurement system and method based on single camera

A three-dimensional digital, image-related technology, applied in measuring devices, instruments, and optical devices, etc., can solve the problems of increasing the complexity of hardware and software, increasing the synchronization transmission time error, and high cost, so as to widen the measurement range, eliminate the Error, effect of simple composition structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

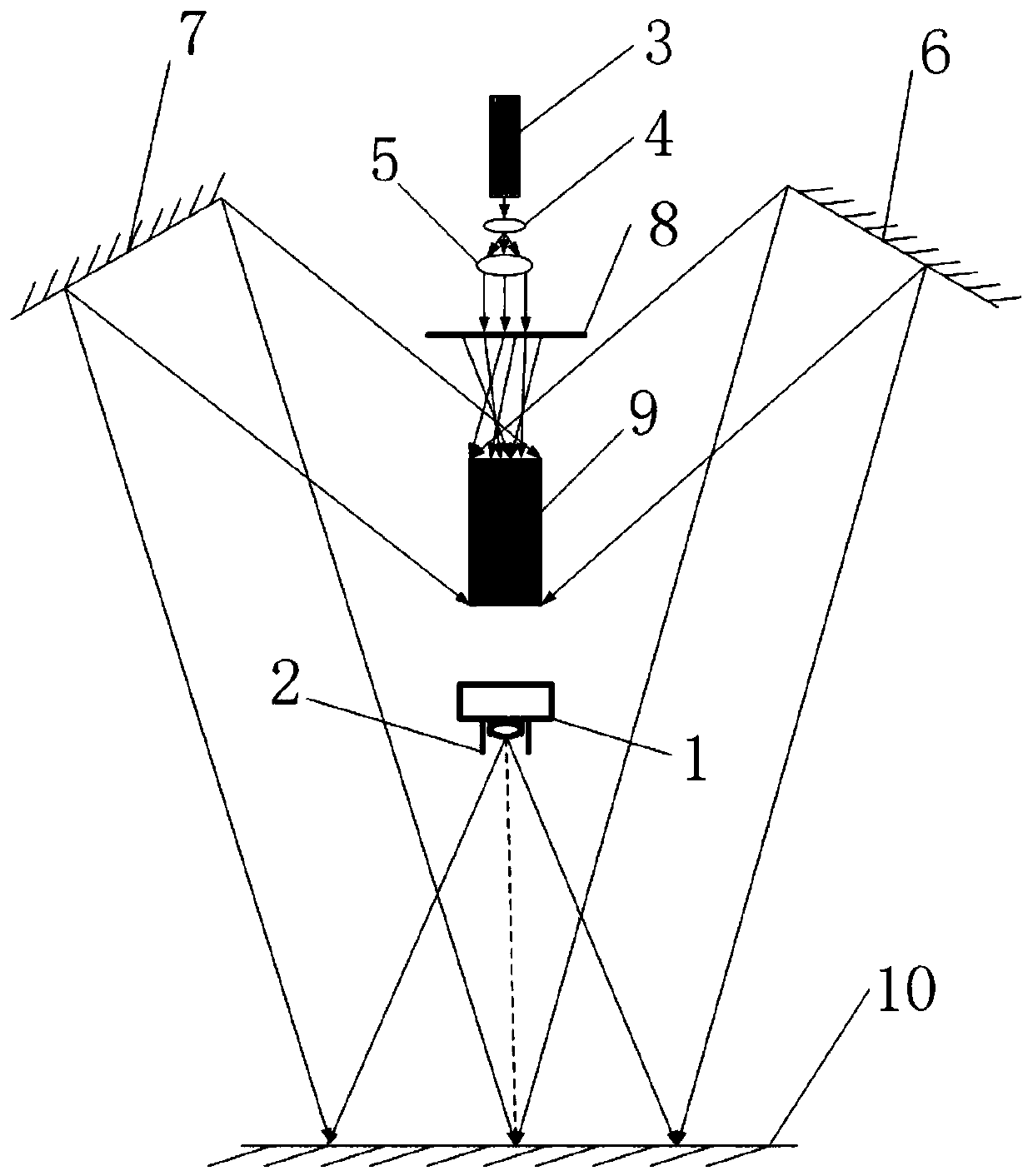

[0027] A high-temperature three-dimensional digital image correlation measurement system based on a single camera, the high-temperature three-dimensional digital image correlation measurement system includes an industrial camera 1, a shutter 2, a He-Ne laser 3, a beam expander 4, a collimating mirror 5, and a plane mirror Ⅰ6, plane mirror Ⅱ7, frosted glass 8, high-temperature test piece 9, plane mirror Ⅲ10, He-Ne laser 3 emits laser light, and the emitted laser light passes through beam expander 4, collimating mirror 5, and ground glass 8 in order to make its speckle spots randomly distributed On the surface of the high-temperature test piece 9 to be tested, as the marking point II, the surface of the high-temperature test piece 9 to be tested is coated with random green speckles with green paint; the calibration plate is located at the high-temperature object to be tested, and is used to detect various parameters of the system;

[0028] Plane mirror Ⅰ6 and plane mirror Ⅱ7 are loc

Embodiment 2

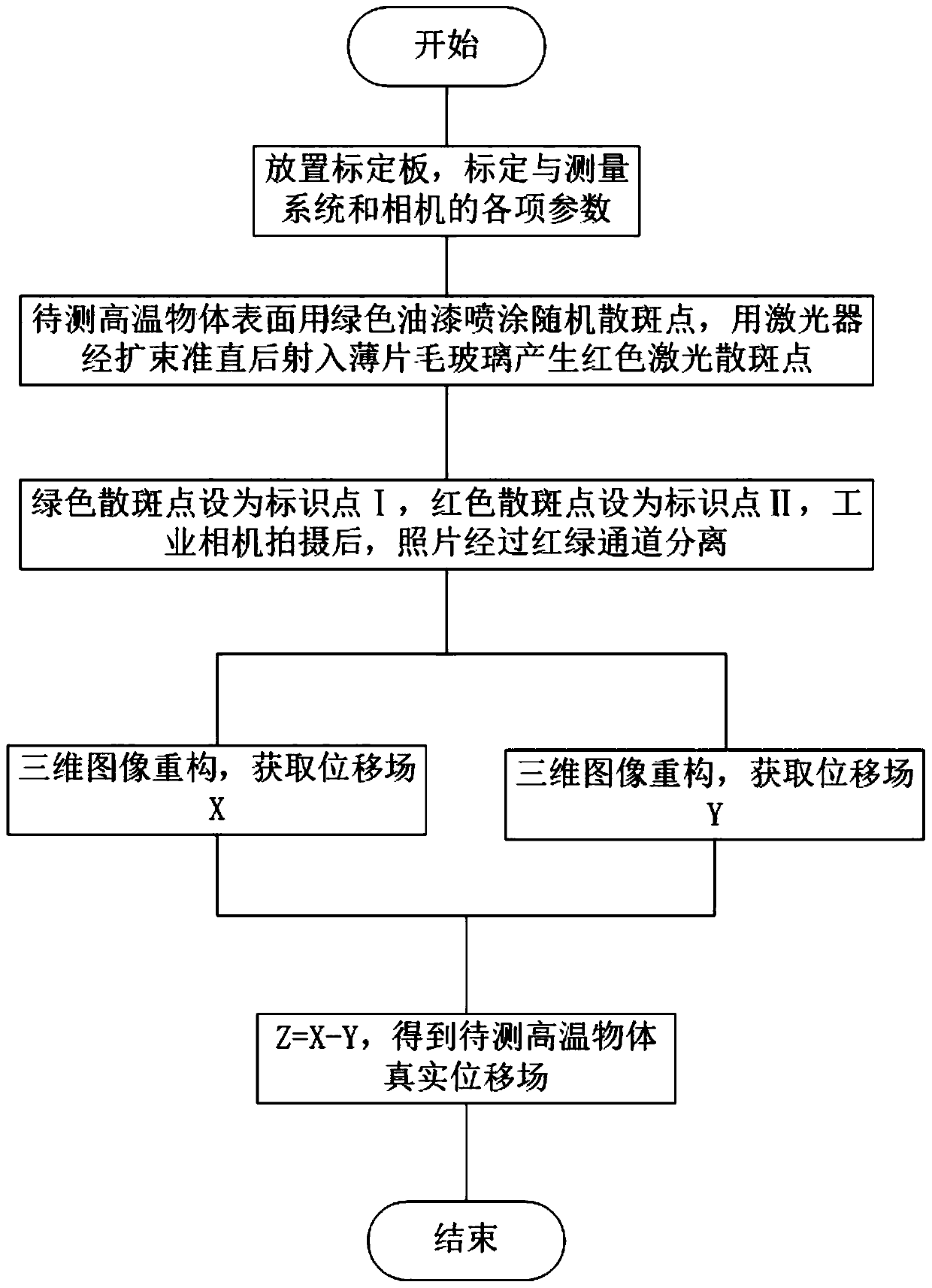

[0030] A high-temperature three-dimensional digital image correlation measurement method based on a single camera, specifically comprising the following steps:

[0031] (1) First, place all the components of the system, place the calibration plate in the center of the system, and obtain various parameters of the system and the camera, including the distance between the plane mirror I6 and the plane mirror II7, the distance between the camera and the plane mirror III, and the parameters of the industrial camera. item parameter.

[0032] (2) According to the measurement requirements of the high-temperature test piece 9 to be tested, the high-temperature test piece 9 to be tested is placed in the center of the system, and the surface is randomly sprayed with green paint as the marking point I.

[0033] (3) Turn on the He-Ne laser 3, and the emitted laser beam is expanded and collimated, and then passes through the thin ground glass 8, so that its speckle spots are randomly distribut

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap