Light emitting assembly and optical module using same

A technology for optical emission components and optical modules, applied in the field of optical communication, can solve the problems of complex emission components and complex assembly, and achieve the effect of simplifying the assembly process, reducing material costs, and saving carrier boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

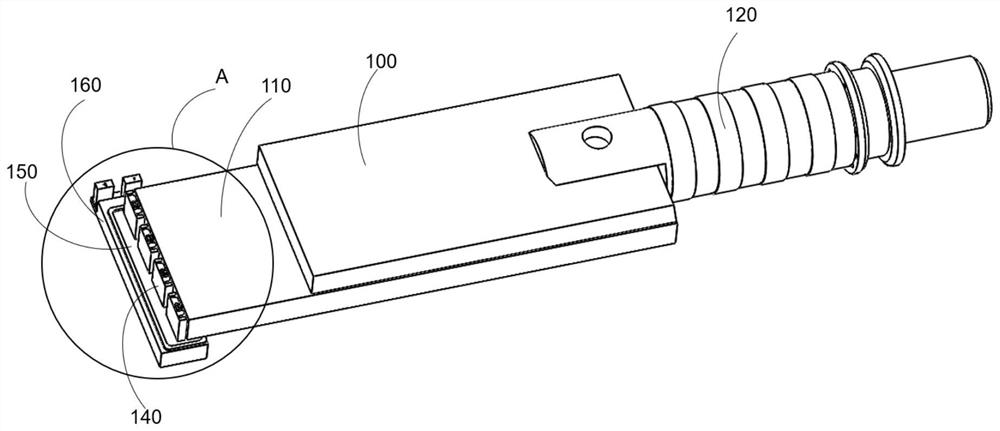

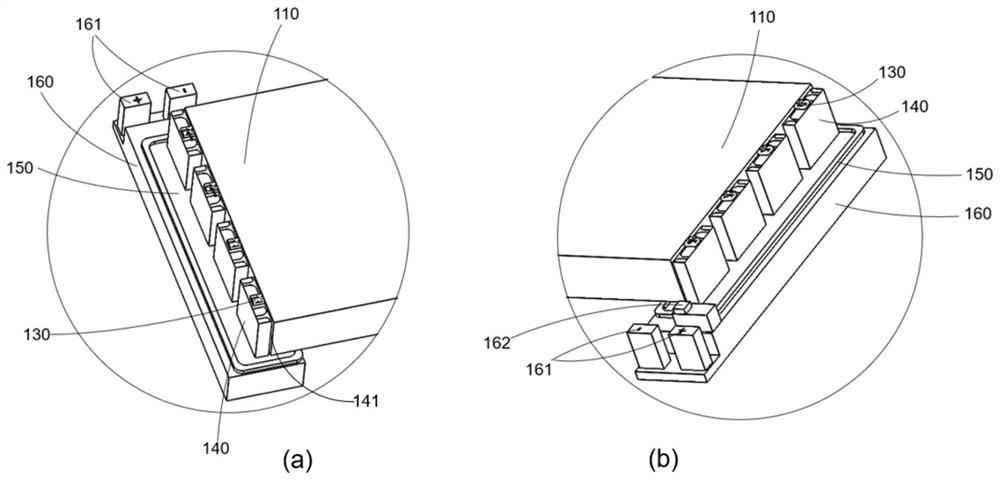

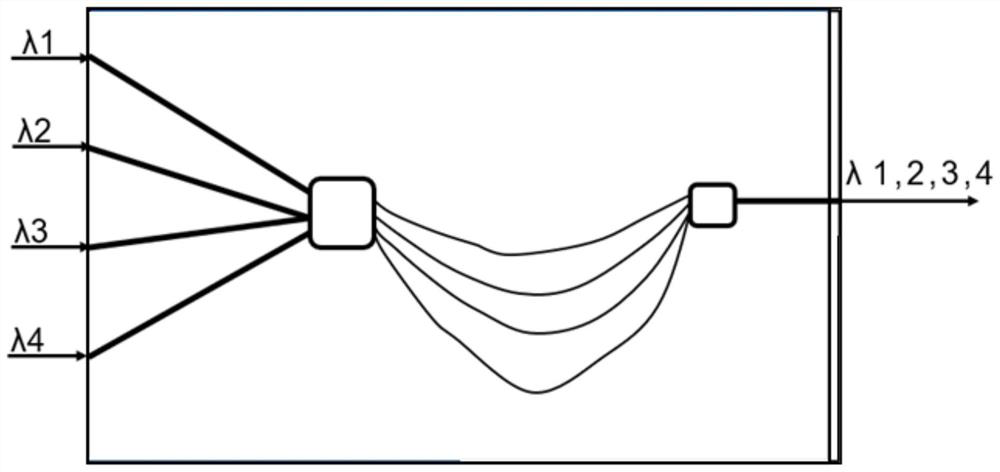

[0028] figure 1 Schematically shows the structure of a light emitting assembly according to an embodiment of the present invention, figure 2 then it shows figure 1 The structure of region A in which figure 2 (a) and figure 2 (b) Area A is shown in more detail from two opposite sides, respectively. like Figure 1-2 As shown, the light emitting component 100 includes a wavelength division multiplexing element (MUX) 110 , a light emitting port 120 and devices in area A.

[0029] In area A, it can be obtained that the light-emitting component 100 further includes a plurality of lasers 130, a plurality of heat dissipation pads 140 corresponding to each laser 130, a heat conduction silicone grease 150 located under the heat dissipation spacers 140, a heat conduction silicone grease 150 located under the heat conduction silicone grease 150 The thermoelectric c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap