Hydraulic villa elevator device saving shaftway space

A villa ladder and shaft technology, which is applied to elevators, transportation and packaging, elevators and other directions in buildings, can solve problems such as small shaft space, save civil construction costs, have a wide range of applications, and reduce material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

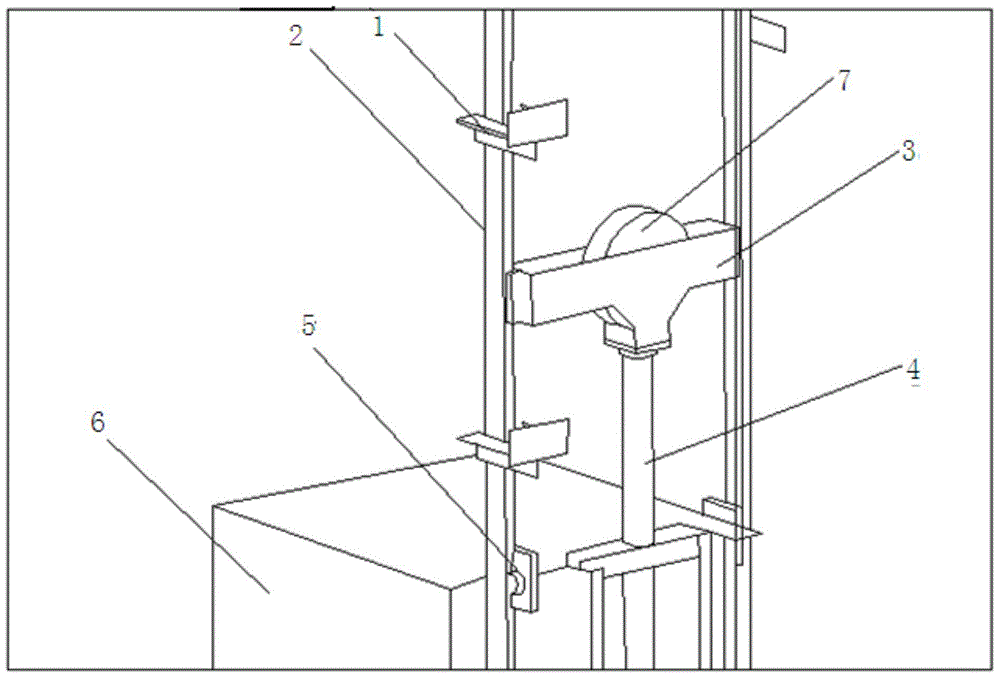

[0013] Such as figure 1 As shown, the present invention provides a hydraulic villa elevator device that saves hoistway space, which includes a vertical guide rail 2, a car 6, a car guide shoe 5, a plunger cylinder, and a plunger guide shoe 4. The guide rail 2 is fixed to the car 6 side, the car 6 is fixedly connected with the car guide shoe 5, and the car guide shoe 5 is connected with the guide rail 2, which can slide up and down along the guide rail 2;

[0014] The plunger cylinder includes the plunger 4, the plunger 4 has a plunger guide shoe 5, the plunger guide shoe 5 has a traction wheel 7, and the plunger guide shoe 5 is located above the car guide shoe 5. The plunger guide shoe 3 can Slide up and down along the guide rail 2;

[0015] One end of a traction rope bypassing the traction sheave 7 is fixed to the car 6 and the other end is fixed to the bottom of the hoistway. The plunger cylinder drives the car 6 to slide along the guide rail 2 through the traction rope. Among the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap