Silicon-based temperature-stable type microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and temperature-stable technology, which is applied in the field of silicon-based temperature-stable microwave dielectric ceramic materials and its preparation, can solve the problems of high sintering temperature, increase in dielectric constant, and high cost of preparation methods, and achieve improved transmission rate, Effect of improving selectivity and ensuring thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

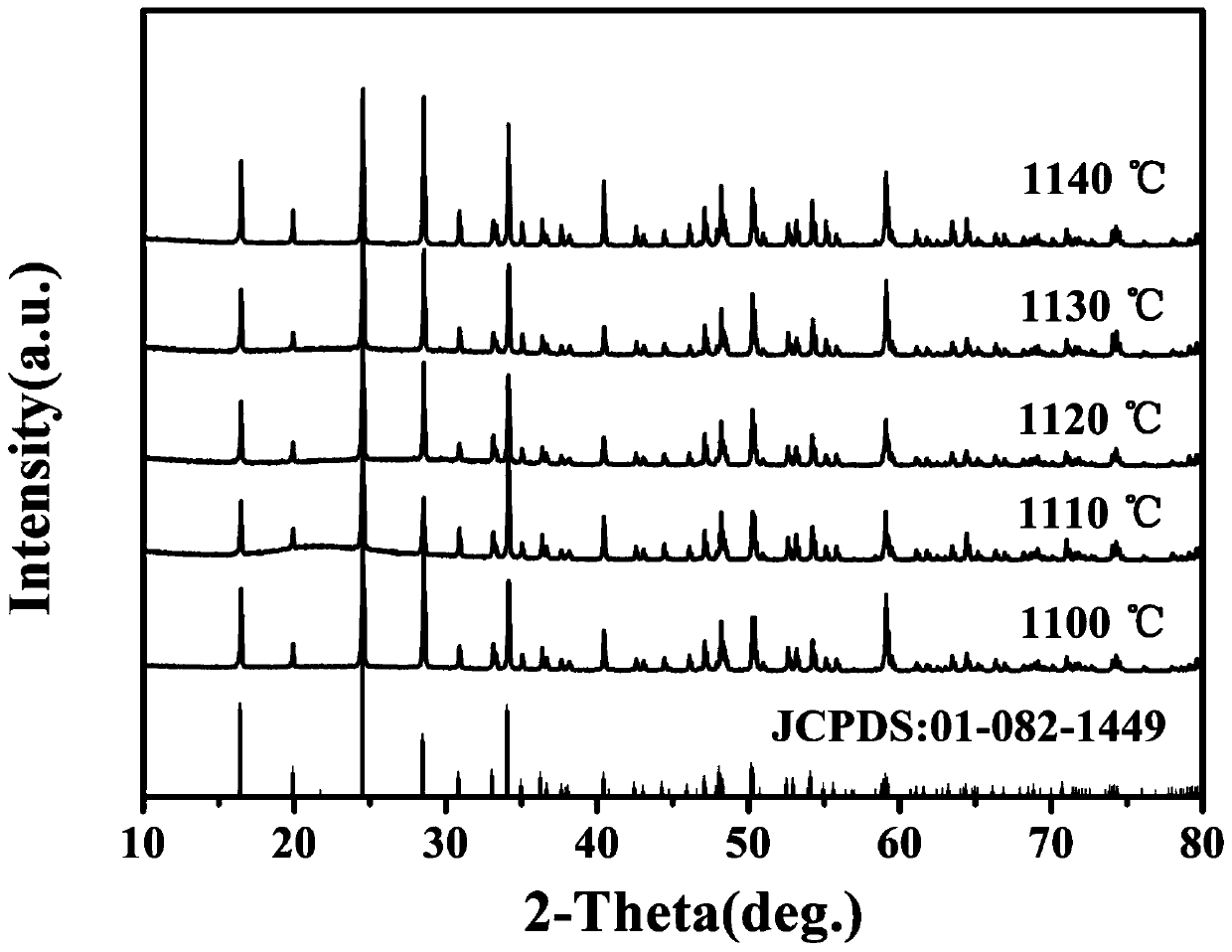

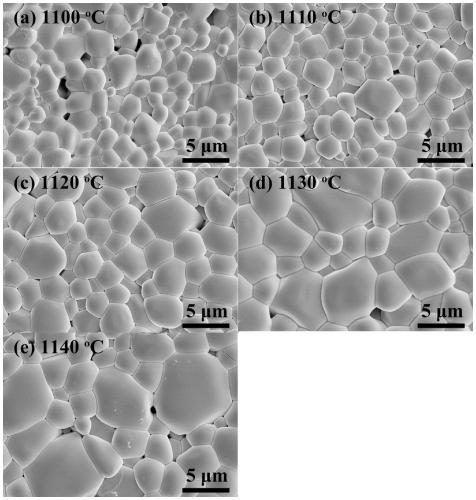

[0027] The composition of the microwave dielectric ceramic material of the present invention is Li 2 CO 3 , Yb 2 o 3 , SiO 2 , the composition of the microwave dielectric ceramic material is LiYbSiO 4 Stoichiometric ratio is carried out proportioning, and its preparation method comprises the following steps:

[0028] (1) with Li 2 CO 3 , Yb 2 o 3 , and SiO 2 As raw material, Yb 2 o 3 Pre-fired at 1000 °C for 2 hours, and then these raw materials were prepared according to LiYbSiO 4 Stoichiometric ratio for proportioning weighing;

[0029] (2) The raw materials weighed in step (1), zirconia ball milling beads, and dehydrated alcohol are placed in a ball mill jar according to a mass ratio of 1:2:2.5, and then the ball mill jar is placed in a planetary ball mill for ball milling, Ball milling for 6 hours; after ball milling, the slurry-like raw material is dried to obtain raw material mixture powder;

[0030] (3) Pressing the mixture powder obtained by drying in step (

Embodiment 1

[0036] (1) with Li 2 CO 3 , Yb 2 o 3 , and SiO 2 As raw material, Yb 2 o 3 Pre-fired at 1000 °C for 2 hours, and then these raw materials were prepared according to LiYbSiO 4 Stoichiometric ratio for proportioning weighing;

[0037] (2) The raw materials weighed in step (1), zirconia ball milling beads, and dehydrated alcohol are placed in a ball mill jar according to a mass ratio of 1:2:2.5, and then the ball mill jar is placed in a planetary ball mill for ball milling, Ball milling for 6 hours; after ball milling, the slurry-like raw material is dried to obtain raw material mixture powder;

[0038] (3) Compressing the mixture powder obtained by drying in step (2) into a block, and calcining at 1000° C. for 4 hours, so that the raw material mixture sample is initially reacted to obtain a sample sintered block;

[0039] (4) Grind the sample sintered block obtained from the preliminary reaction in step (3) into a powder, then put the powder, zirconia ball milling beads, an

Embodiment 2

[0046] (1) with Li 2 CO 3 , Yb 2 o 3 , and SiO 2 As raw material, Yb 2 o 3 Pre-fired at 1000 °C for 2 hours, and then these raw materials were prepared according to LiYbSiO 4 Stoichiometric ratio for proportioning weighing;

[0047] (2) The raw materials weighed in step (1), zirconia ball milling beads, and dehydrated alcohol are placed in a ball mill jar according to a mass ratio of 1:2:2.5, and then the ball mill jar is placed in a planetary ball mill for ball milling, Ball milling for 6 hours; after ball milling, the slurry-like raw material is dried to obtain raw material mixture powder;

[0048] (3) Compressing the mixture powder obtained by drying in step (2) into a block, and calcining at 1020° C. for 4 hours to make a preliminary reaction of the raw material mixture sample to obtain a sample sintered block;

[0049] (4) Grind the sample sintered block obtained from the preliminary reaction in step (3) into a powder, then put the powder, zirconia ball milling beads

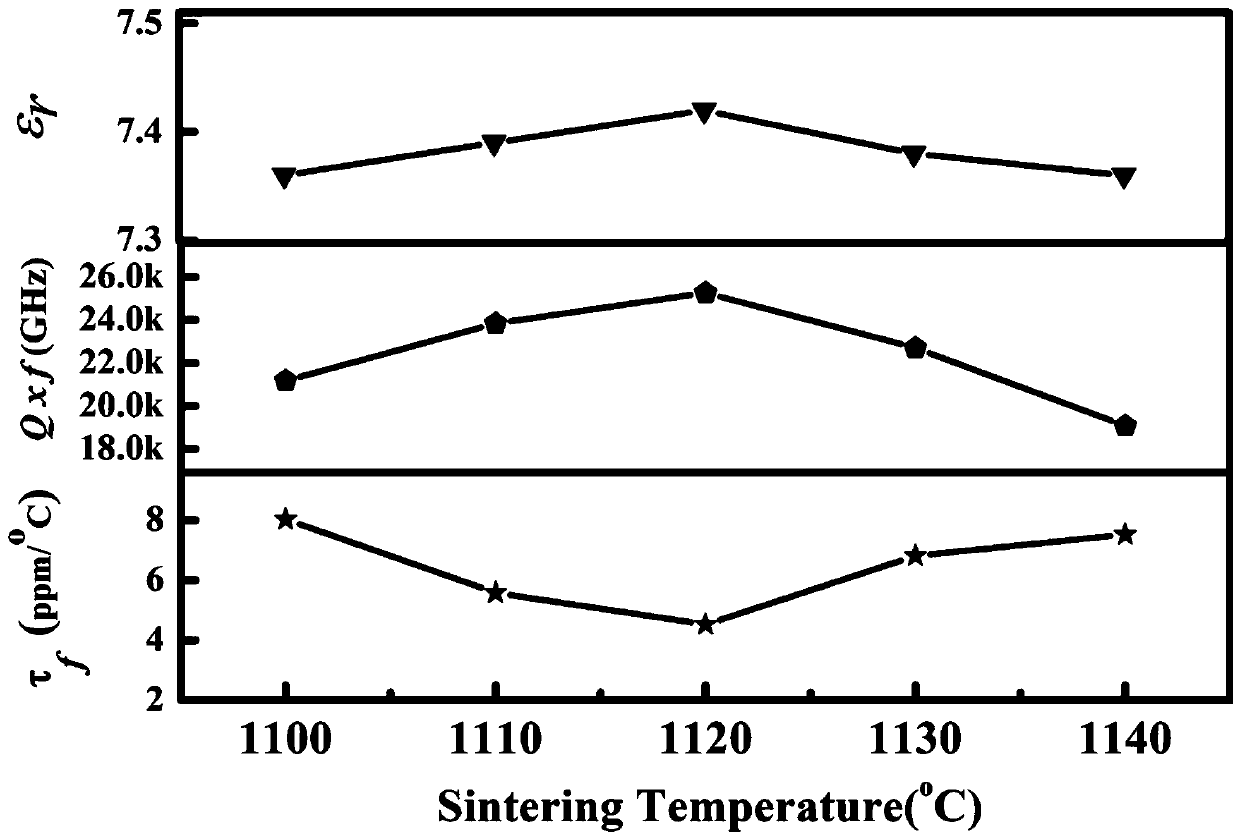

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality factor | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap