Preparation method of Ni single atom/oxygen defect copper tungstate photo-anode

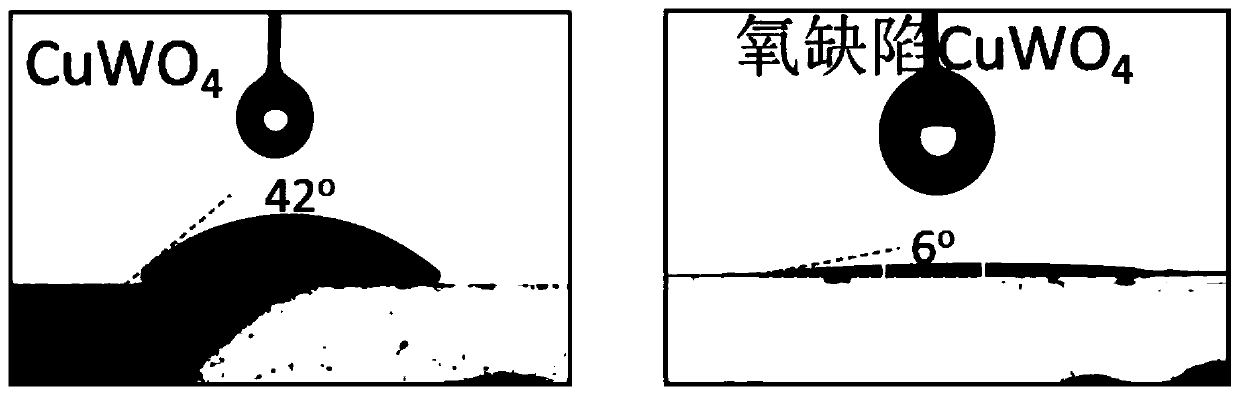

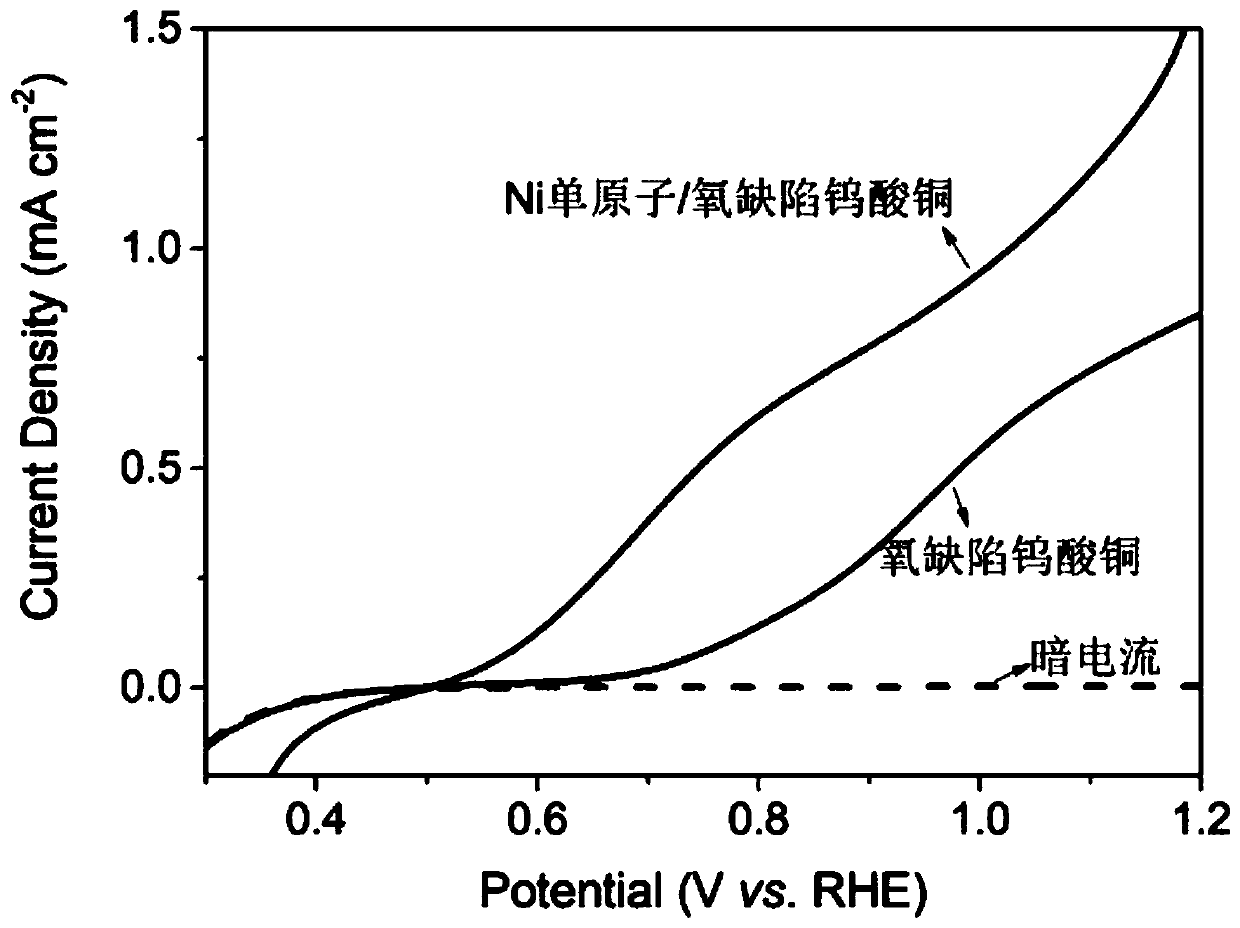

An oxygen deficiency, copper tungstate technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Anode, semiconductor metal single-atom agglomeration, etc., to shorten the charge transfer distance, improve the light absorption efficiency, and increase the photocurrent density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

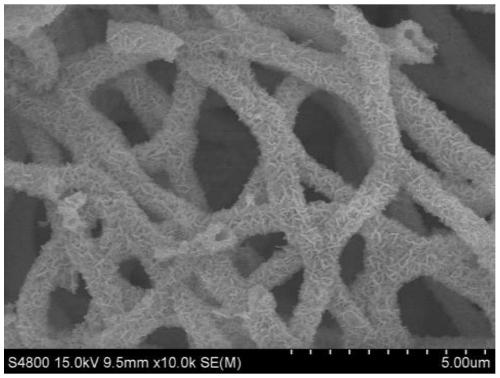

[0021] A preparation method of a Ni single atom / oxygen-deficient copper tungstate photoanode, the specific steps are as follows: use a pipette gun to pipette 100 μL of polyvinyl alcohol, and spin-coat it on the surface of FTO glass to enhance the viscosity of the FTO surface. Fix the FTO glass on the roller of the static spinning device. Weigh 0.6g of polyacrylonitrile powder and add it to 10ml of dimethylformamide solution, stir overnight, then transfer to an electrospinning machine, pass 18V high voltage, the spinning solution is drawn into nanofibers, and the nanofibers on the surface of FTO are collected. Fibers are pretreated at low temperature at 250°C, followed by high-temperature carbonization at 900°C to obtain carbon nanofiber electrodes (CNFs); the aqueous precursor solution of copper acetate and ammonium tungstate is prepared, transferred to the reaction kettle, and the CNFs electrode is added to the precursor solution, sealed, placed in a constant temperature dryin

Embodiment 2

[0024] A preparation method of a Ni single atom / oxygen-deficient copper tungstate photoanode, the specific steps are as follows: use a pipette gun to pipette 100 μL of polyvinyl alcohol, and spin-coat it on the surface of FTO glass to enhance the viscosity of the FTO surface. Fix the FTO glass on the roller of the static spinning device. Weigh 1.0g of polyacrylonitrile powder and add it to 10ml of dimethylformamide solution, stir overnight, then transfer to an electrospinning machine, pass 15V high-voltage electricity, the spinning solution is drawn into nanofibers, and the nanofibers on the surface of FTO are collected. Fibers are pretreated at low temperature at 250°C, followed by high-temperature carbonization at 900°C to obtain carbon nanofiber electrodes (CNFs); the aqueous precursor solution of copper nitrate and ammonium tungstate is prepared, transferred to the reaction kettle, and the CNFs electrode is added to the precursor solution, sealed, and placed in a 150°C cons

Embodiment 3

[0027] A preparation method of a Ni single atom / oxygen-deficient copper tungstate photoanode, the specific steps are as follows: use a pipette gun to pipette 100 μL of polyvinyl alcohol, and spin-coat it on the surface of FTO glass to enhance the viscosity of the FTO surface. Fix the FTO glass on the roller of the static spinning device. Weigh 0.7g of polyacrylonitrile powder and add it to 10ml of dimethylformamide solution, stir overnight, then transfer to an electrospinning machine, pass 18V high-voltage electricity, the spinning solution is drawn into nanofibers, and the nanofibers on the surface of FTO are collected. The fibers are pretreated at low temperature at 250°C, followed by high-temperature carbonization at 950°C to obtain carbon nanofiber electrodes (CNFs); the aqueous solution of precursors of copper acetate and ammonium tungstate is prepared, transferred to the reaction kettle, and the CNFs electrodes are added to the precursor solution, sealed, placed in a cons

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap