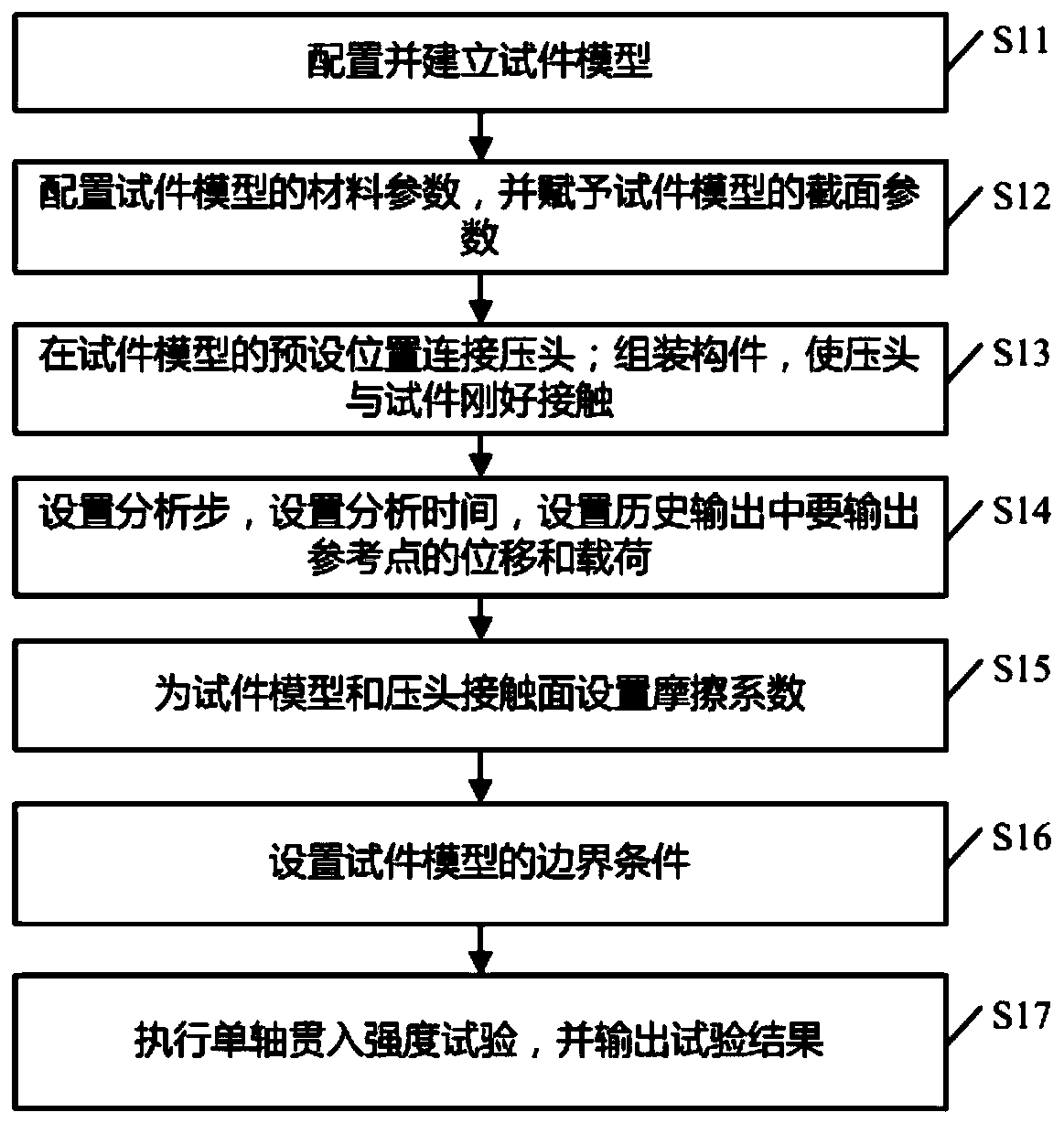

Modeling method for finite element simulation uniaxial penetration strength test, equipment and readable storage medium

A modeling method and uniaxial penetration technology, applied in strength characteristics, design optimization/simulation, measurement devices, etc., can solve problems such as difficulty in meeting actual needs, complicated test operations, and heavy preparation workload, and achieve easy mix ratio Design, save cumbersome steps, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Those of ordinary skill in the art can realize that the units and algorithm steps of the examples described in conjunction with the embodiments disclosed herein can be implemented by electronic hardware, computer software, or a combination of the two. In order to clearly illustrate the relationship between hardware and software Interchangeability. In the above description, the composition and steps of each example have been generally described according to their functions. Whether these functions are executed by hardware or software depends on the specific application and design constraints of the technical solution. Those skilled in the art may use different methods to implement the described functions for each specific application, but such implementation should not be regarded as exceeding the scope of the present invention.

[0026] The block diagrams shown in the drawings are merely functional entities and do not necessarily correspond to physically separate entities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap