Large-diameter bent and twisted steel pipe column bracket positioning and assembling method

An assembly method and technology of steel pipe columns, which are applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the problems of inability to meet precision control, waste of human and financial resources, and occupy a large space, saving time and materials. consumption, high work efficiency, and the effect of controlling assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

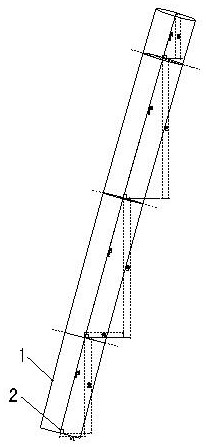

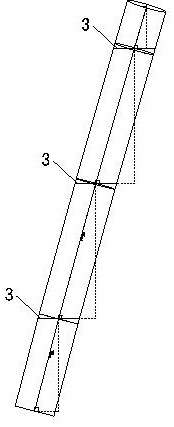

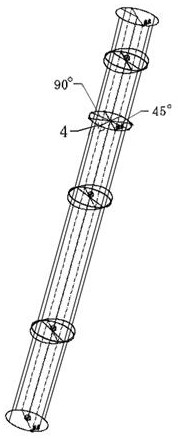

[0032] The present invention relates to the production of the positioning and assembly size control of the large-diameter twisted steel pipe column 1 corbel. In the production process of the large-diameter bent and twisted steel pipe column splicing, in order to ensure that the assembled space size of each corbel 8 of the bent and twisted steel pipe column is accurate , The production process is fast and simple. We use the computer lofting technology and the construction method of corbel 8 pre-splicing to invent the positioning and assembly method of large-diameter curved and twisted steel pipe column corbels.

[0033] refer to Figure 1-8 , the positioning and assembly method of the large-diameter bent and twisted st

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap