Preparation method of composite phosphorus removal adsorbent lanthanum oxycarbonate loading montmorillonite

A phosphorus adsorbent, lanthanum oxycarbonate technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve problems such as low removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

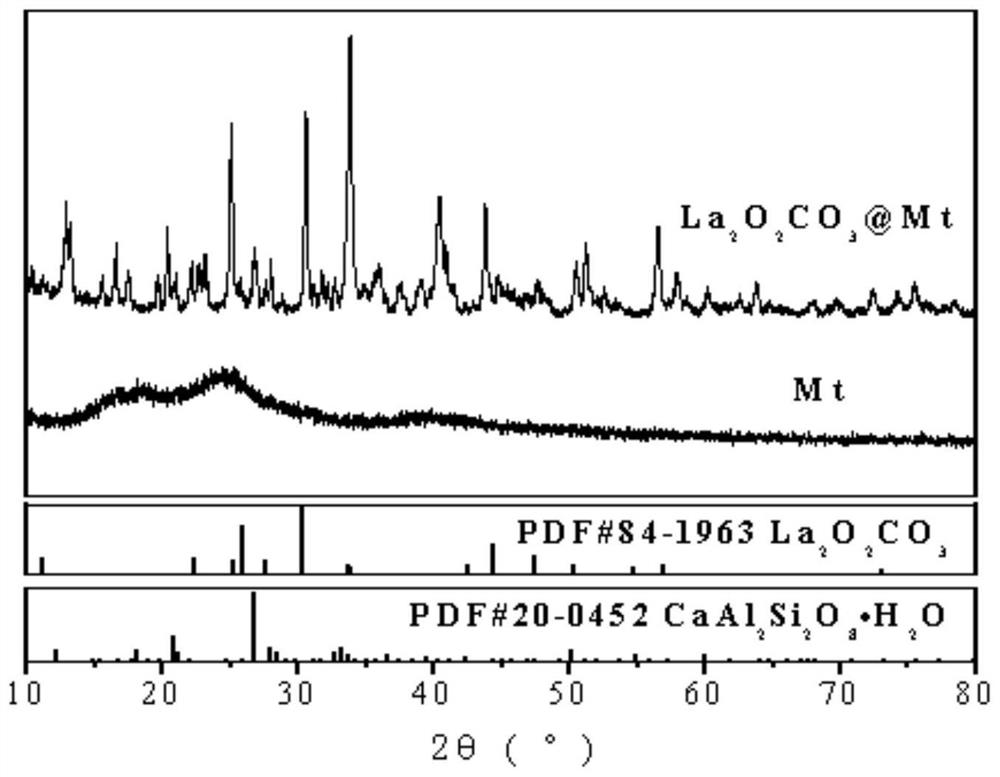

[0029] Embodiment 1: The preparation method of the composite dephosphorization adsorbent of the present embodiment, lanthanum oxycarbonate loaded montmorillonite, is carried out according to the following steps:

[0030] S1: Put 10g of montmorillonite in 100mL of sulfuric acid solution with pH = 1, stir for 2 hours at room temperature with a constant temperature magnetic stirrer, after the reaction is complete, filter and wash the modified montmorillonite until neutral, and place in a drying oven inside, baked at 110° C. for 6 hours, and ground to obtain the modified montmorillonite (Mt) used in the experiment.

[0031] S2: According to the molar ratio n(lanthanum nitrate):n(glycine)=1:2, weigh a certain amount of lanthanum nitrate and glycine into a beaker, add a small amount of deionized water, and stir magnetically for 30 minutes; The mass ratio of de-stonening is 0.5:1, add a certain amount of modified montmorillonite, continue magnetic stirring to make it evenly mixed, then

Embodiment 2

[0036] The La obtained in step S3 2 o 2 CO 3 @Mt for adsorption performance test, the steps are as follows: Weigh 50mg La 2 o 2 CO 3 @Mt, add 50mg / L of PO 4 3- In solution, at room temperature for PO 4 3- The solution is adsorbed, and the removal effect is characterized by the removal rate R, which is calculated according to the following formula:

[0037] R(%)=(c 0 -c) / c 0 ×100%

[0038] Among them, c 0 Represents PO before adsorption 4 3- concentration, c represents PO after adsorption 4 3- concentration. The result is as Figure 6 shown, from Figure 6 As can be seen from the La 2 o 2 CO 3 @Mt on PO 4 3- The adsorption reaches equilibrium in about 120 minutes, and the removal rate can reach 98.1% to 99.5%.

Embodiment 3

[0040] Dissolve 50 mg / L of KH with HCl or NaOH 2 PO 4 The solution was adjusted to pH=1~7, and then 50mg / LLa 2 o 2 CO 3 @Mt carried out the adsorption experiment, and the operation steps were the same as in Example 2.

[0041] The result is as Figure 7 shown, from Figure 7 It can be seen that when the pH of the solution is in the range of 1 to 7, the pH effect on La 2 o 2 CO 3 @Mt adsorption effect is less affected, La 2 o 2 CO 3 @Mt on PO 4 3- The removal rate is maintained above 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap