Sewage treatment equipment with friction nano-generator

A technology of sewage treatment equipment and nano-generators, applied in the fields of friction generators, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low efficiency, great influence of environmental factors, and insufficient efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

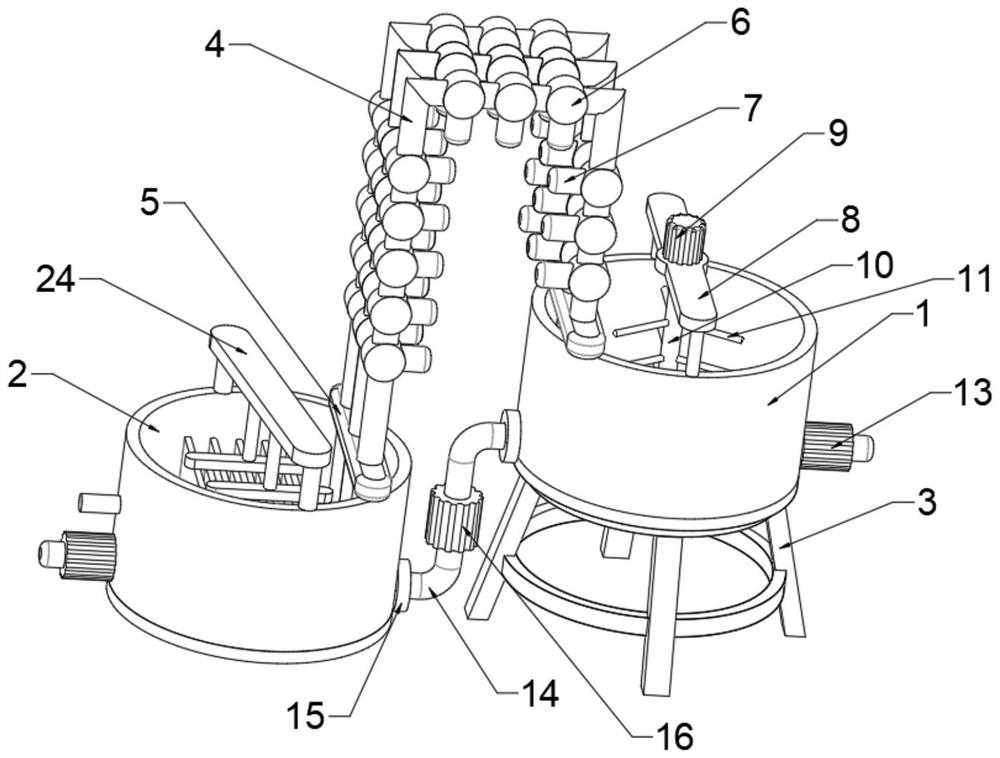

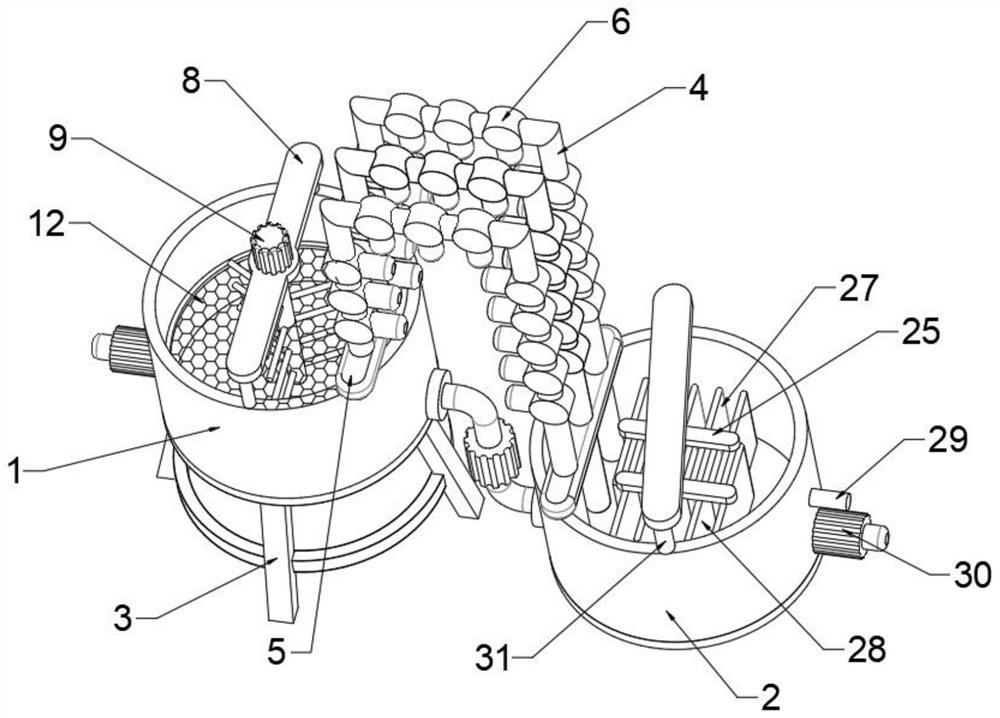

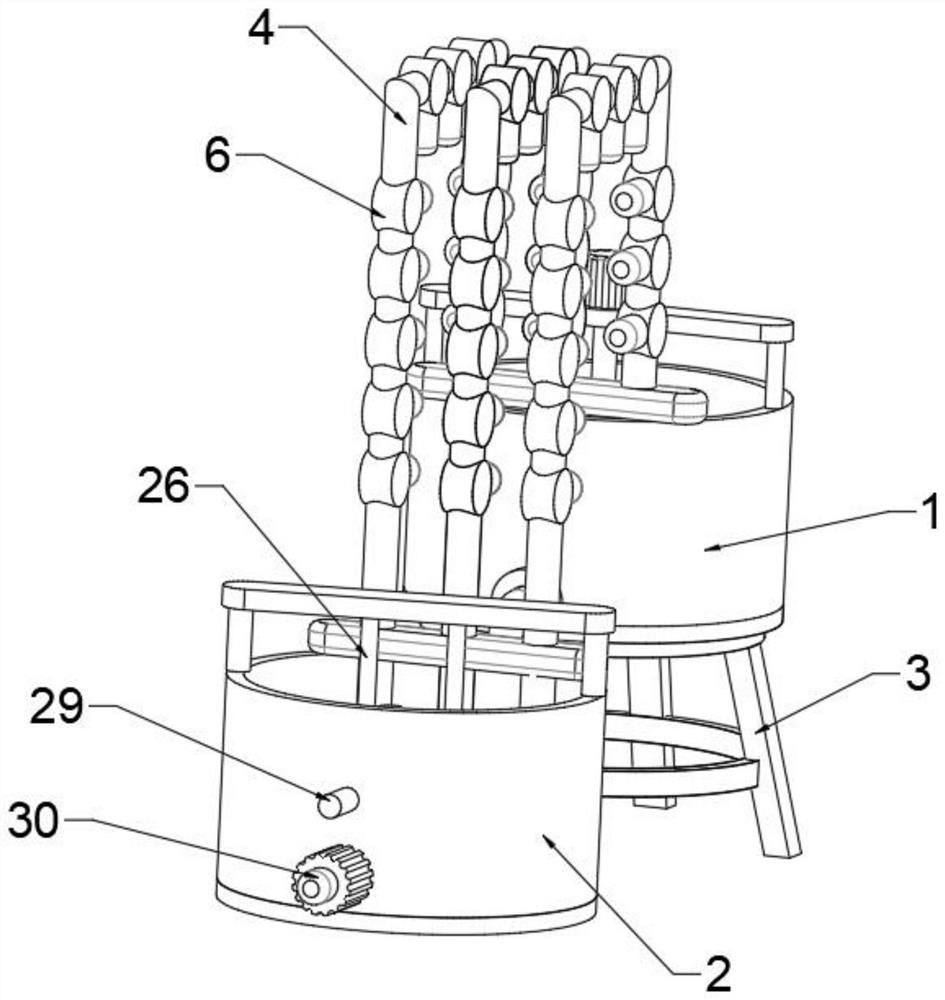

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0036] Wherein, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

[0037] refer to figure 1 , figure 2 and image 3The shown one kind of frictional nano generator environmental protection sewage treatment equipment includes a reservoir 1 and a treatment pond 2, which are respectively used for preliminary sewage storage and effluent treatment. The reservoir 1 is equipped with a rough sewage treatment component, which can play a role in sewage treatment. A certain filtration and p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap