Software-defined LED driving power supply

An LED driver, software-defined technology, applied in electrical components, electrical equipment structural parts, cooling/ventilation/heating renovation, etc., can solve the problem of power supply performance degradation, inability to work, etc., to avoid performance degradation, prevent Burning, strong connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

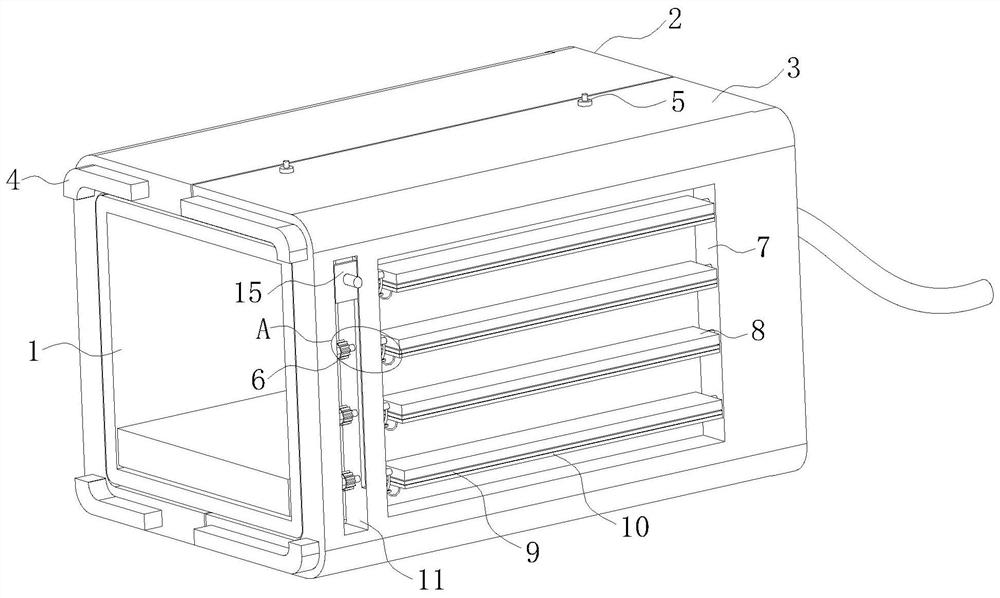

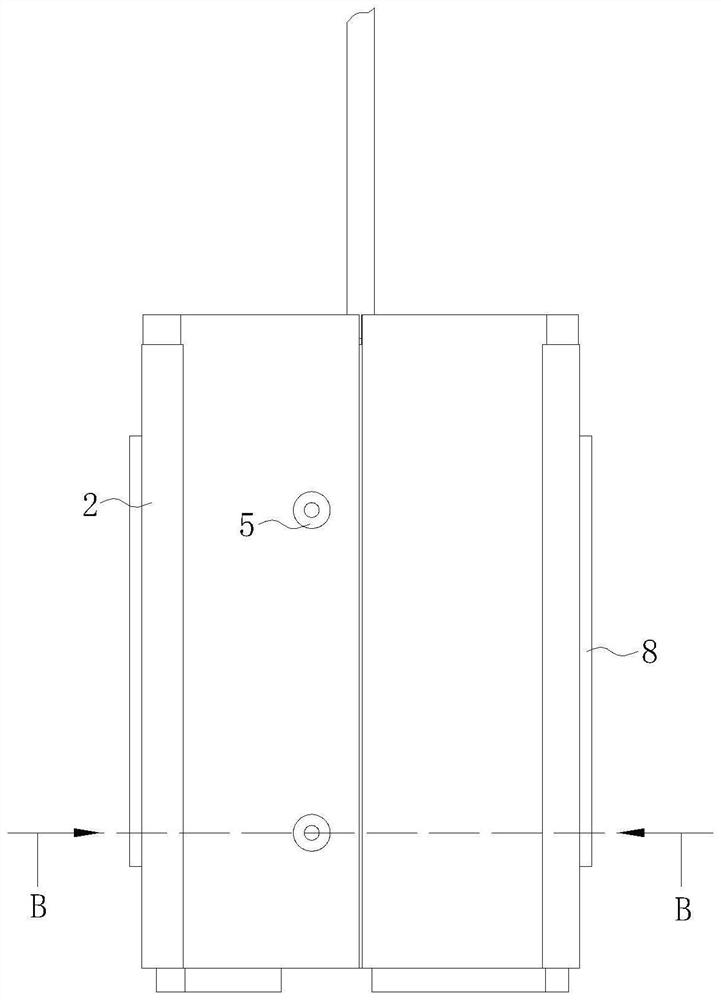

Image

Examples

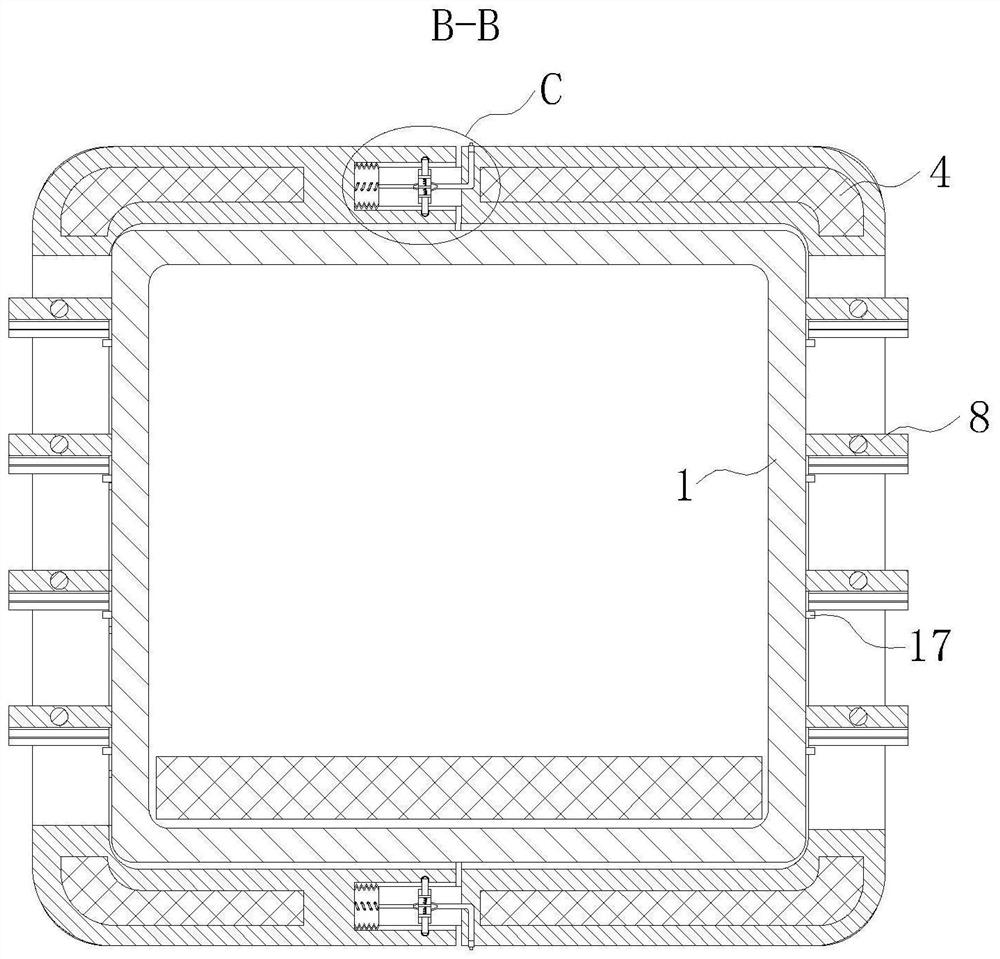

Embodiment approach

[0036] As an embodiment of the present invention, rubber rollers 23 are evenly arranged on the edge of the part of the rotating rod 12 located in the circular through groove 24; both ends of the rotating shaft of the rubber roller 23 are fixedly connected by springs On the edge of the rotating rod 12; when working, the rubber roller 23 is pressed against the inner wall of the circular through groove 24 by a spring, and then the position of the rotating rod 12 can be fixed to prevent the external force from easily causing the rotating rod 12 to rotate , to avoid changing the position of the heat conduction plate 8 and affecting the effect it actually wants to achieve, and this design makes the position of the rotating rod 12 slightly offset, and then in the process of rotating the heat conduction plate 8 and does not want to achieve When its end face is attached to the outer wall of the drive power supply body 1, there may be a buffer space, which will not cause the heat conduction

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap