Six-axis CNC precision automatic lathe

A kind of heart machine, six-axis technology, applied in the field of six-axis heart machine, can solve the problems of low processing efficiency, long tool adjustment time, long tool adjustment stroke, etc., to achieve good practicability, shorten tool adjustment stroke, and improve processing efficiency. double the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The features of the present invention and other related features are further described in detail below through embodiments, so as to facilitate the understanding of those skilled in the industry:

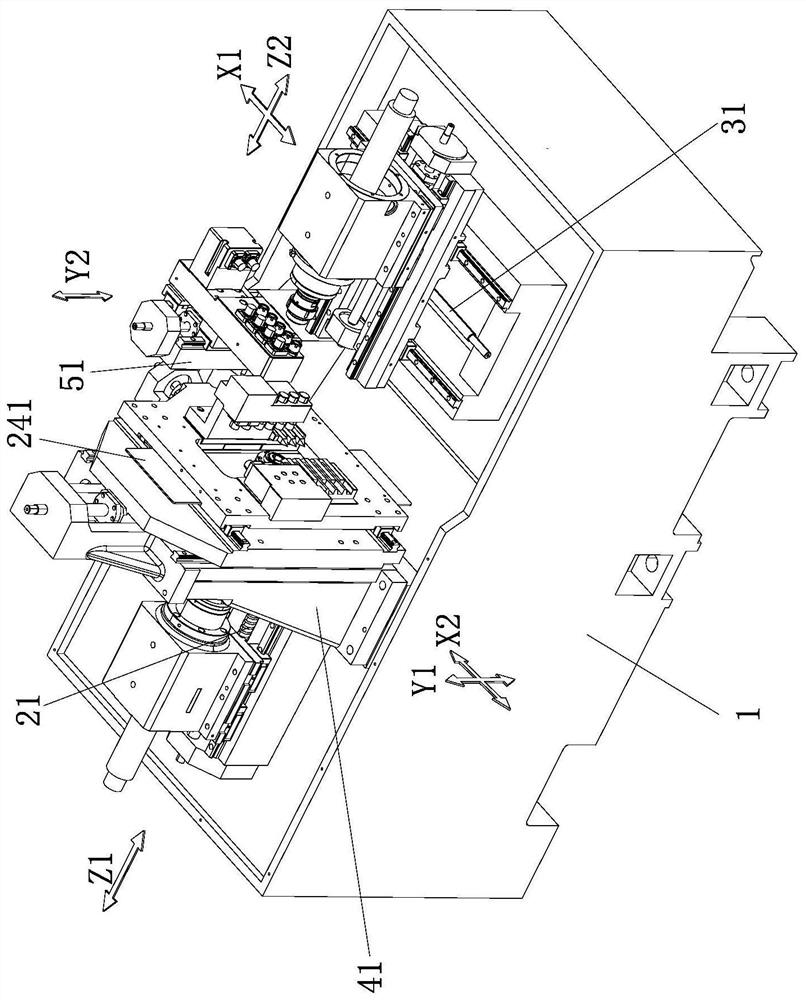

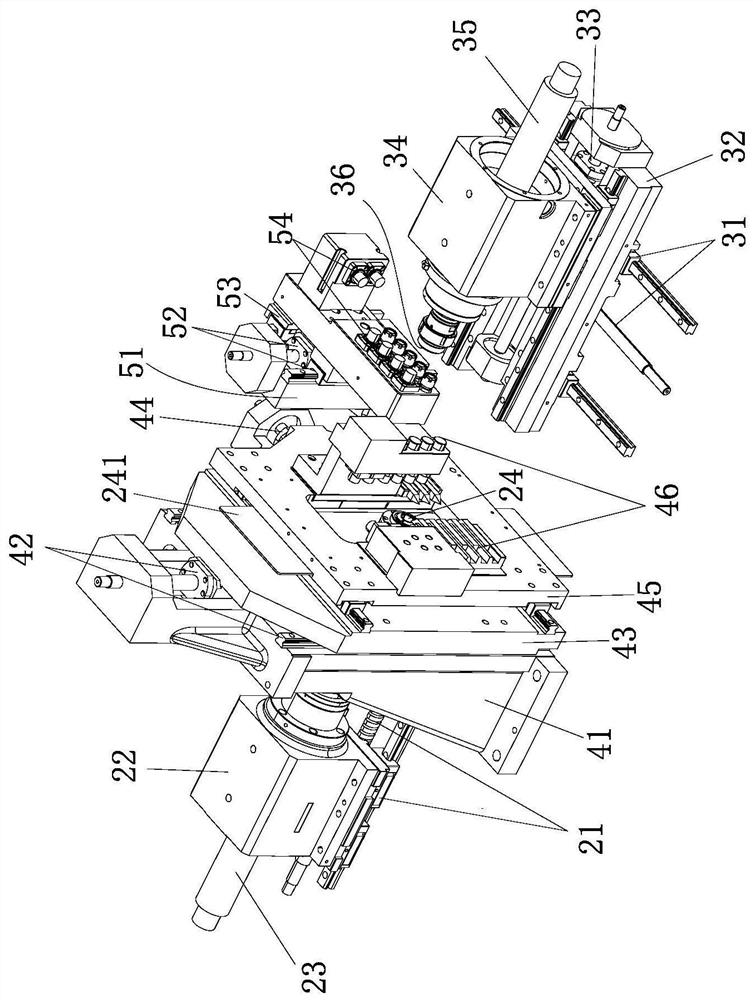

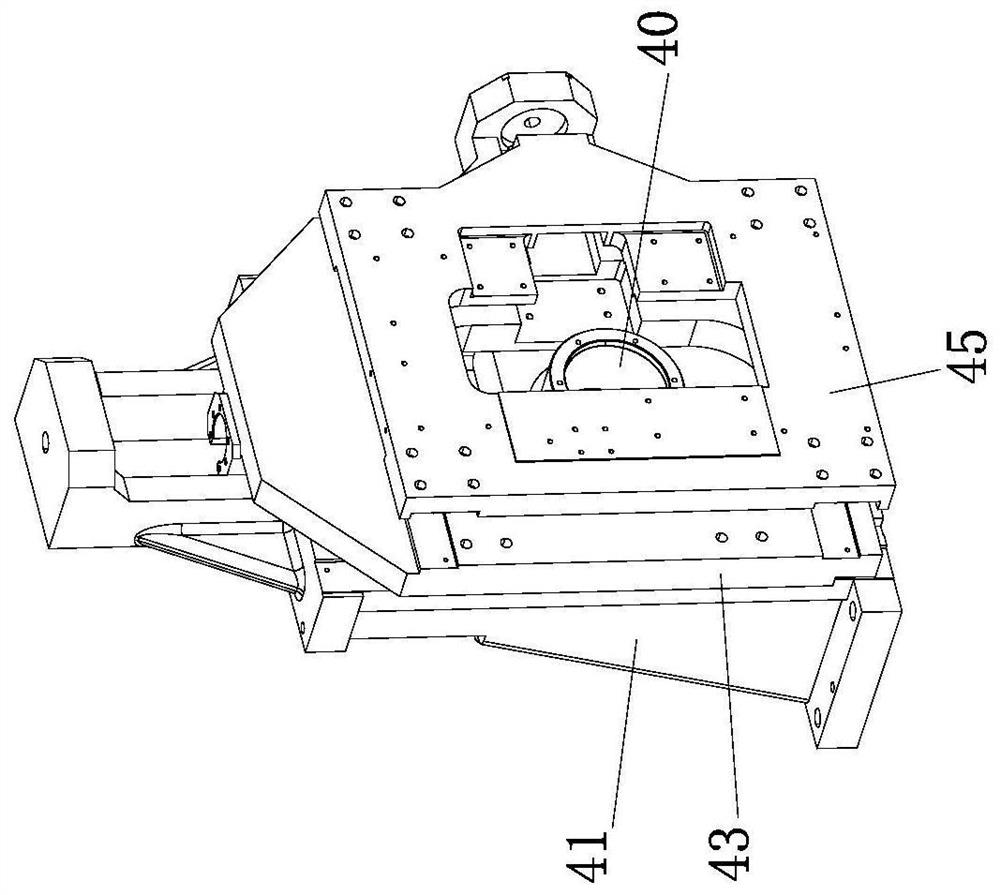

[0024] Such as Figure 1 to Figure 5 As shown, a six-axis walking machine includes a bed 1, on which a first electric spindle box 22 is connected through a Z1 axis linear transmission mechanism 21, and an X1 axis is connected through an X1 axis linear transmission mechanism 31. The sliding plate 32, the X1-axis sliding plate 32 is connected to the second electric spindle box 34 through the Z2-axis linear transmission mechanism 33, the first electric spindle box 22 is installed with a Z1-direction electric spindle 23, the Z1-direction electric spindle 23 The front end is connected with a first chuck 24 for clamping a workpiece, the second electric spindle box 34 is equipped with a Z2-direction electric spindle 35, and the front end of the Z2-direction electric spindle 35 is connecte

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap