Cerium-doped aluminum nitride material as well as preparation method and luminescence characteristic regulation and control method thereof

A technology of luminescent characteristics and aluminum nitride, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of difficult precise control of oxygen impurity content, no adjustment of aluminum nitride luminescent materials, etc., and achieve the effect of simple and effective preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

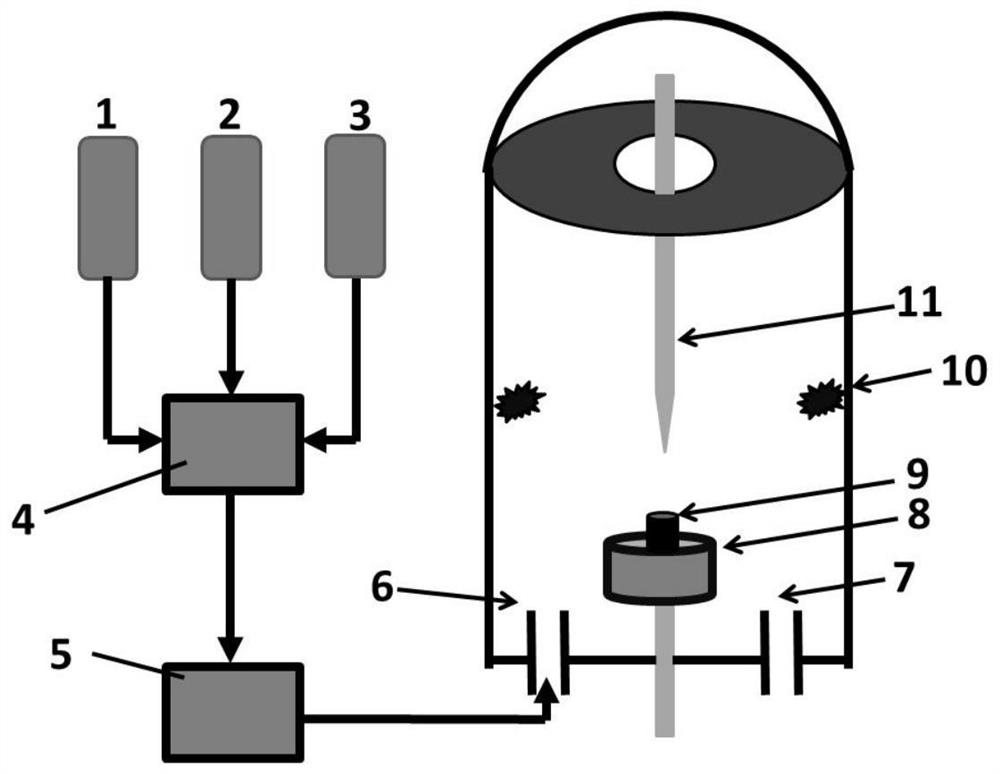

[0040] Aluminum powder and ceria (CeO 2 ) powders are mixed evenly in a molar ratio of 100:1, put into an agate ball mill jar, and then add agate balls, and the ball mill jar is filled with high-purity argon gas and put into a planetary ball mill to start ball milling. After the ball milling, take out 5g of the mixed powder, use a tablet press to briquette, and press into a cylinder with a diameter of 1.8cm and a height of 2cm. The mixture is compacted and placed in the graphite pot 9, put figure 1 In the copper pot anode 8 in the reaction chamber of the direct current arc discharge device, the copper pot anode 8 is passed into cooling water; the reaction chamber is evacuated first, and then filled with nitrogen gas through the nitrogen storage tank 2 and repeatedly scrubbed to remove oxygen in the reaction chamber and water. The gas storage tank 2 provides nitrogen with a flow rate of 100 sccm, and the hydrogen storage tank 1 provides auxiliary gas H 2 The flow rate of 30sccm

Embodiment 2

[0044] Aluminum powder and ceria (CeO 2 ) powders are mixed evenly in a molar ratio of 100:1, put into an agate ball mill jar, and then add agate balls, and the ball mill jar is filled with high-purity argon gas and put into a planetary ball mill to start ball milling. After the ball milling, take out 5g of the mixed powder, use a tablet press to briquette, and press into a cylinder with a diameter of 1.8cm and a height of 2cm. The mixture is pressed into pieces and placed in a graphite pot, and placed in the anode of the copper pot in the reaction chamber of the DC arc discharge device, and the anode of the copper pot is fed with cooling water; firstly, the reaction chamber is evacuated, and then filled with nitrogen gas for repeated washing. Oxygen and water are removed from the reaction chamber. The nitrogen storage tank 2 is provided with nitrogen at a flow rate of 100 sccm without adding any auxiliary gas. When the air pressure is 50kPa, close the inflation pipe and start

Embodiment 3

[0048] Aluminum powder and ceria (CeO 2 ) powder is mixed evenly in a molar ratio of 100:1, put into an agate ball mill jar, then add agate balls, fill the ball mill jar with high-purity argon, and then put it into a planetary ball mill to start ball milling. After the ball milling, take out 5g of the mixed powder, use a tablet press to briquette, and press into a cylinder with a diameter of 1.8cm and a height of 2cm. The mixture is pressed into pieces and placed in a graphite pot, and placed in the anode of the copper pot in the reaction chamber of the DC arc discharge device, and the anode of the copper pot is fed with cooling water; firstly, the reaction chamber is evacuated, and then filled with nitrogen gas for repeated washing. Oxygen and water are removed from the reaction chamber. The nitrogen storage tank 2 provides nitrogen with a flow rate of 100 sccm, and the oxygen storage tank 3 provides auxiliary gas oxygen with a flow rate of 1 sccm or 3 sccm to flow into the sta

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap