Fireproof transformer with clamping device

A technology for a clamping device and a transformer, applied in the field of transformers, can solve the problems of inconvenient use, poor heat dissipation, and poor internal heat dissipation effect, and achieve the effect of enhanced practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

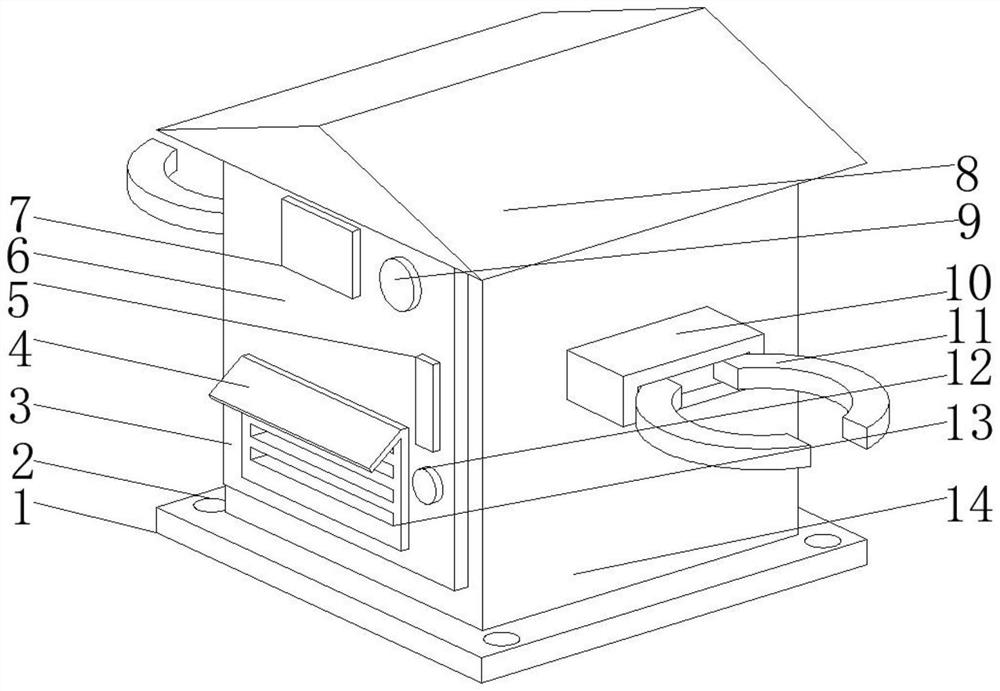

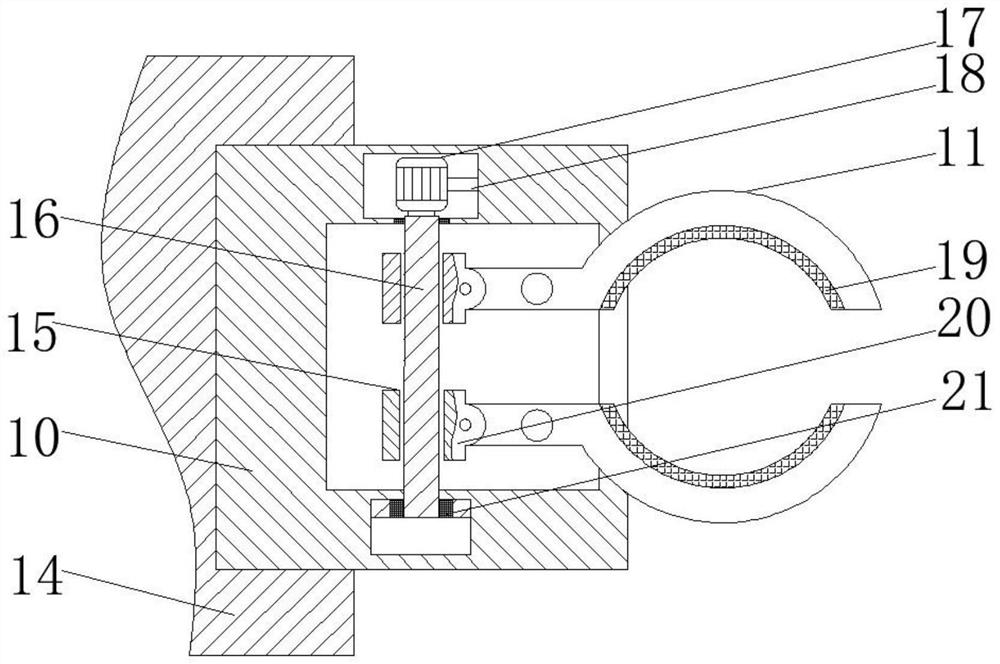

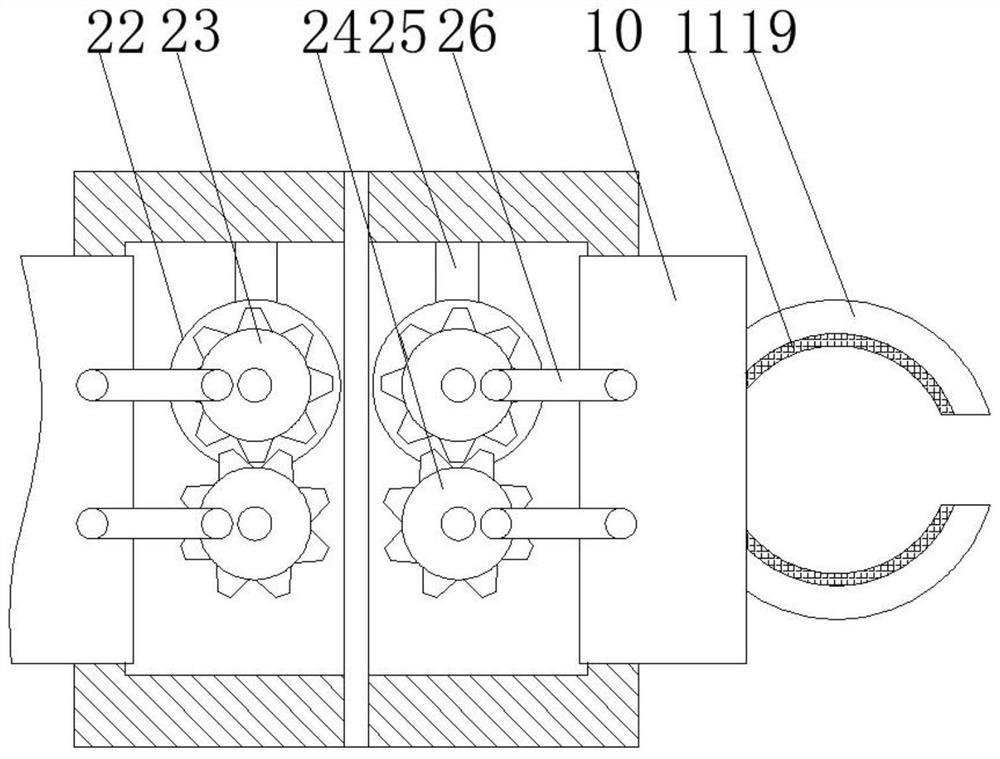

[0031] see Figure 1-4 , a fire-resistant transformer with a clamping device, including a cabinet body 14, expansion plates 10 are provided on both sides of the cabinet body 14, a clamping block 11 is provided inside the expansion plate 10, and one end of the clamping block 11 is flexibly connected There is a slider 20, the inside of the clamping block 11 is fixedly connected with a rubber pad 19, the inside of the slider 20 is provided with a screw hole 15, and the inside of the screw hole 15 is provided with a screw rod 16, and one end of the screw rod 16 is fixedly connected to a No. 1 servo motor 17 One side of No. 1 servo motor 17 is fixedly connected with No. 1 connector 18, bearings 21 are arranged between the two ends of screw rod 16 and telescopic plate 10, No. 2 servo motor 22 is provided at one end of telescopic plate 10, No. 2 servo One side of the motor 22 is fixedly connected with a No. 2 connector 25, the output shaft of the No. 2 servo motor 22 is fixedly connecte

Embodiment 2

[0034] see figure 1 and 4 , the present embodiment is further optimized on the basis of Embodiment 1, specifically, the front of the cabinet 14 is provided with a cabinet door 6, the top of the cabinet 14 is fixedly connected with an upper cover 8, and the bottom of the cabinet 14 An installation base plate 1 is fixedly connected, and an installation hole 2 is provided around the top of the installation base plate 1 .

[0035] Specifically, the front of the cabinet door 6 is provided with a ventilation panel 3 , and the front of the ventilation panel 3 is provided with a ventilation hole 13 .

[0036] Specifically, a stepless speed regulation motor 27 is provided on the back side of the ventilation plate 3 , the output shaft of the stepless speed regulation motor 27 is fixedly connected with a fan blade 29 , and a fan groove 28 is arranged outside the fan blade 29 .

[0037] In this embodiment, when the equipment needs to be ventilated, the stepless speed regulation motor 27 dr

Embodiment 3

[0039] see figure 1 and 4 , the present embodiment is optimized as follows on the basis of Example 1 or Example 2, specifically, the upper end of the ventilation hole 13 is provided with a rain shield 4, and one side of the rain shield 4 is provided with a keyhole 12 and a handle 5.

[0040] Specifically, the key hole 12 is circular, and the handle 5 is rectangular.

[0041] Specifically, the top of the cabinet door 6 is provided with a display screen 7, and one side of the display screen 7 is provided with a warning light 9, the display screen 7 is rectangular, and the warning light 9 is circular.

[0042] Specifically, an induction controller 30 is provided inside the cabinet body 14 , and there are multiple induction controllers 30 , and the plurality of induction controllers 30 are evenly distributed inside the cabinet body 14 .

[0043] In this embodiment, by setting the upper cover 8 into a triangle, the rainwater can flow down quickly when it rains, and the setting of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap