Chalcogenide glass sphere preparation method and used extrusion forming device

A technology of chalcogenide glass extrusion molding, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low efficiency and large material loss, and achieve high efficiency, high material utilization rate, simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 is used to illustrate the preparation method of chalcogenide optical glass spheres and the extrusion molding device used in the present invention. Example 1 is only to demonstrate the feasibility of the technique.

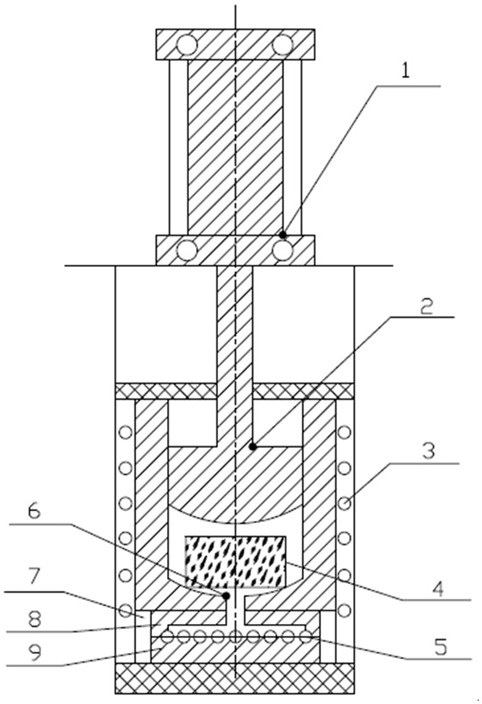

[0029] The extrusion molding device used in Example 1 of the present invention includes a molding die and an extrusion device. Wherein, the molding die is made up of mold cover 7, hemispherical upper mold 8 and hemispherical lower mold 9 three parts. The hemispherical upper die 8 and the hemispherical lower die 9 are respectively processed with 9 corresponding hemispherical holes, and the hemispherical upper die 8 and the hemispherical lower die 9 are combined to form 9 spherical molding die cavities 5 . Die cover 7, hemispherical upper die 8 and hemispherical lower die 9 materials are metal materials. The extrusion device is composed of cylinder 1, extrusion rod 2, guide sleeve 6 and softening furnace 3. The cylinder 1 is installed above the so

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap