Kitchen waste oil purification treatment method and treatment device based on method

A technology for the purification and treatment of kitchen waste oil, applied in chemical instruments and methods, filtration treatment, sedimentation treatment, etc., can solve the problems of slow oil separation and treatment, easy environmental pollution of sediment, catalyst poisoning, etc. Improve efficiency and strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

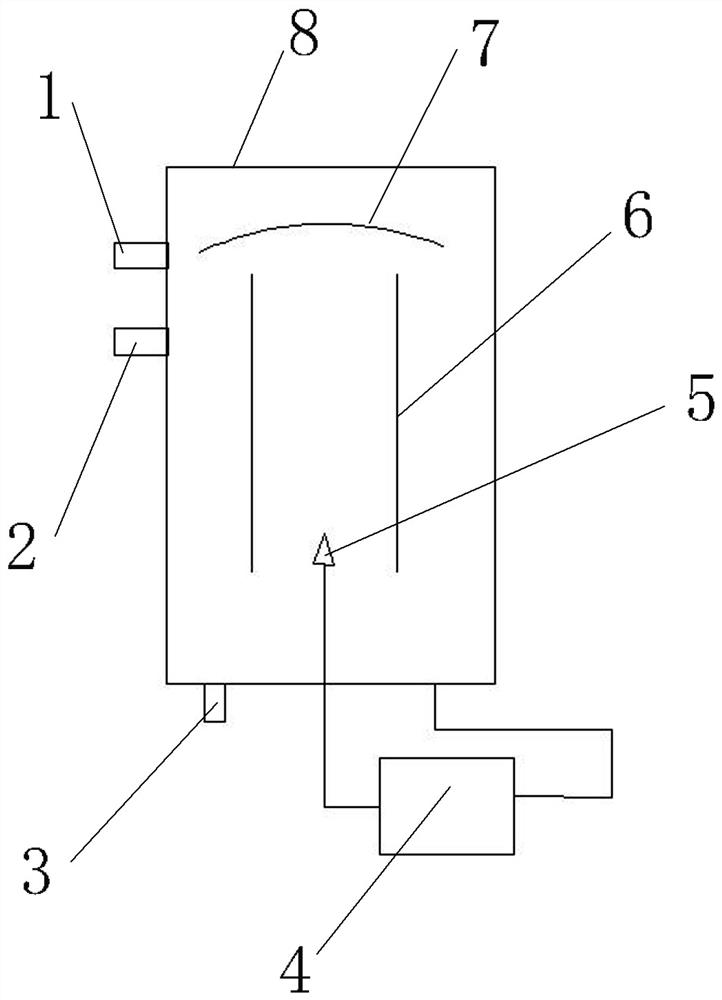

[0017]The present invention will be further described below in conjunction with the drawings.

[0018]The present invention provides a method for purification and treatment of kitchen waste oil, which is achieved through the following steps:

[0019]1) The kitchen waste oil is heated and filtered, some solid impurities are filtered and then settled and separated, and crude oil and oil residue are obtained after the settlement and separation;

[0020]2) After crude oil is filtered, add waste glycerin at a ratio of 10:1 to waste glycerin needed for the production of crude oil and biodiesel, add a certain amount of water, waste glycerin is a strong polar solvent with a density of 1.26, and water is a polar solvent , The density is 1.0, the two become emulsion after mixing with crude oil, the density increases, the adsorption power is stronger, the ability to wash the colloid is stronger, and then separated by the butterfly centrifuge, the centrifugal force is large, the separation is sufficient ,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap