Self-ventilation heat dissipation type oil-immersed transformer

An oil-immersed transformer and heat-dissipating technology, which is applied in the direction of transformer/inductor cooling, transformer/inductor parts, electrical components, etc., can solve the problem that heat cannot be dissipated to the outside in time, affecting the normal use of transformers, transformer oil decomposition, etc. problem, to achieve the effect of improving heat conduction effect, light weight, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

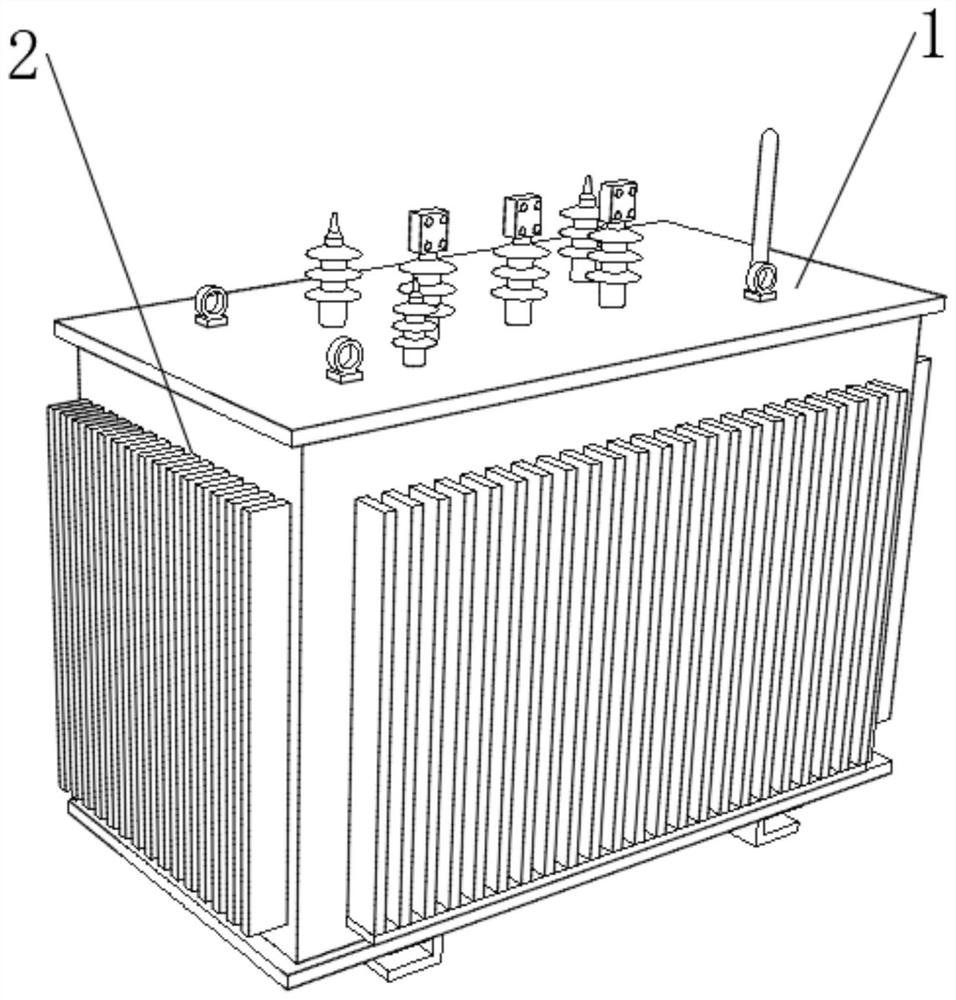

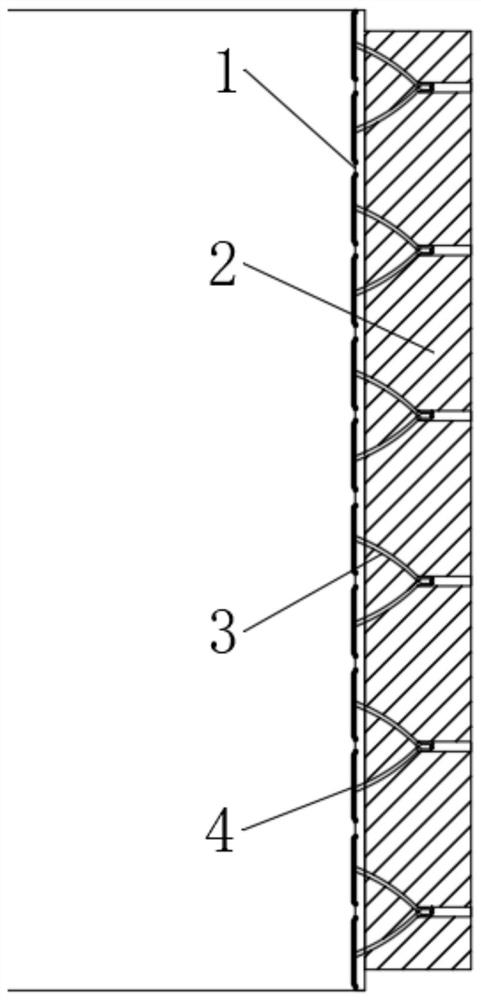

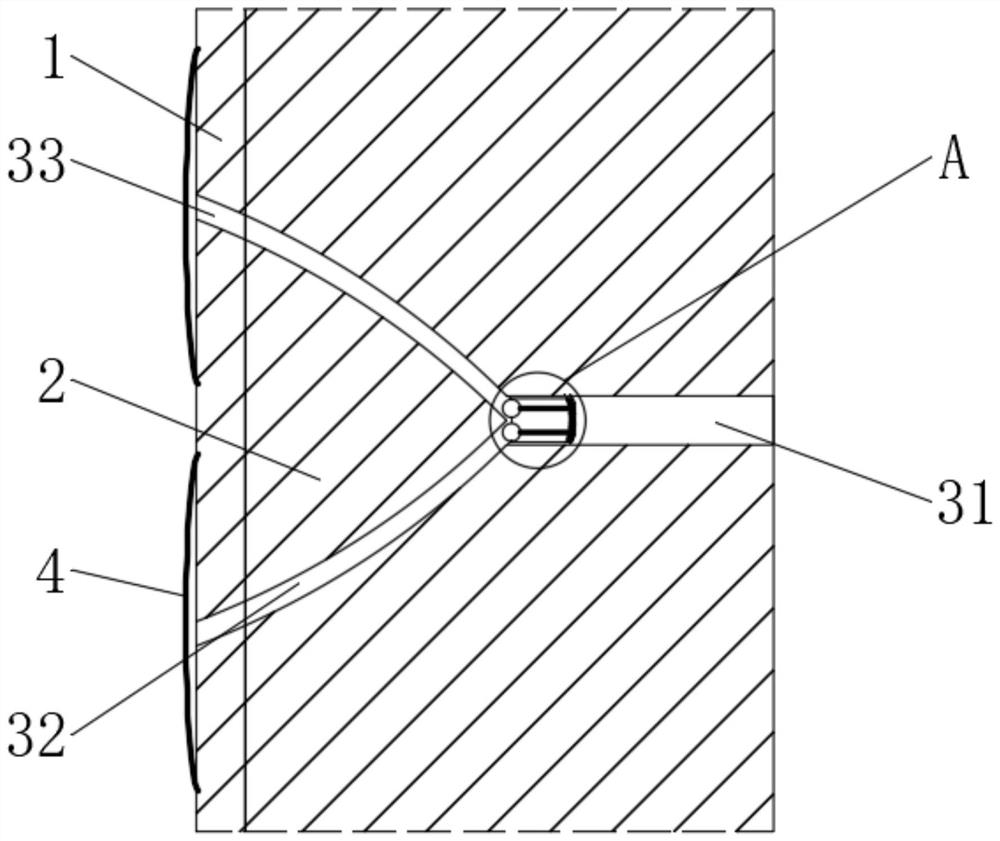

[0043] see Figure 1-2 , a self-ventilating heat dissipation oil-immersed transformer, including a transformer body 1, a plurality of evenly distributed heat dissipation fins 2 are connected to the outer end of the transformer body 1, and the heat dissipation fins 2 and the transformer body 1 are integrally formed, The heat dissipation fins 2 are provided with a plurality of evenly distributed ventilation and heat dissipation holes 3 .

[0044] The volume of a pair of sub-inflatable holes 32 is greater than the volume of the main vent hole 31, the maximum extension distance of the elastic backguy 7 is consistent with the length of the sub-inflatable holes 32, and the volume of the sub-inflatable holes 32 will ensure that after the migration of the magnetic transfer balloon 6 The gas supplemented by the outside should be more than the original gas in the main ventilation hole 31, so as to fully ensure the heat exchange effect, and the elastic stay wire 7 should ensure that the mag

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap