Potato seed active conveying device for potato seeder

An active conveying and seeder technology, applied in the field of agricultural equipment, can solve the problems of missed potato seeding, poor fluidity, and lack of access to seed cups, and achieve the effects of reducing labor costs, simple device structure, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

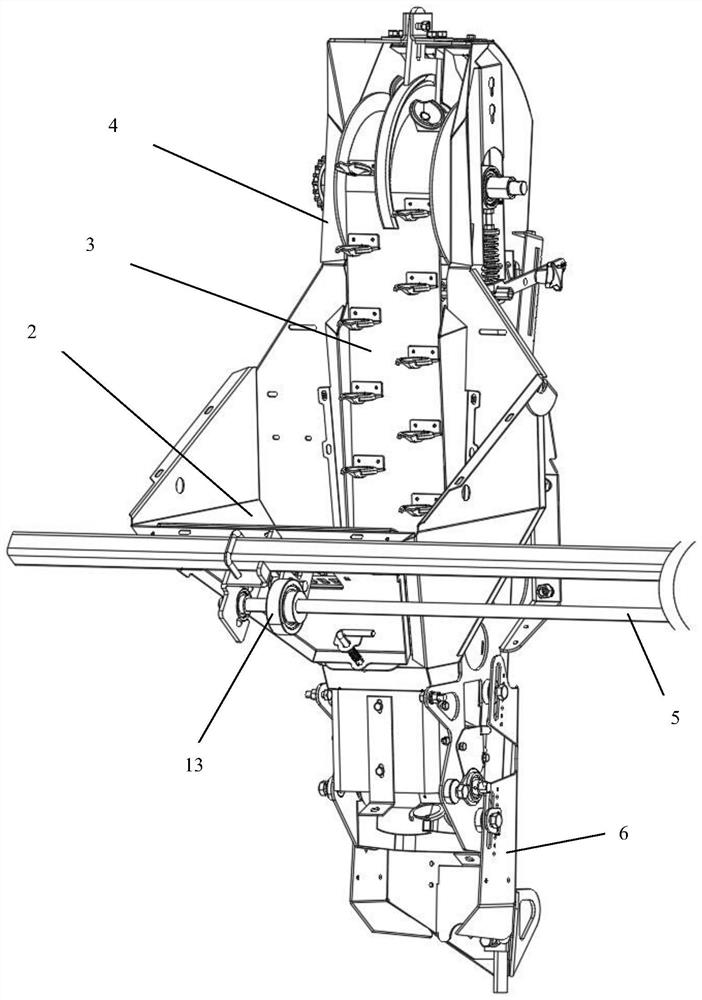

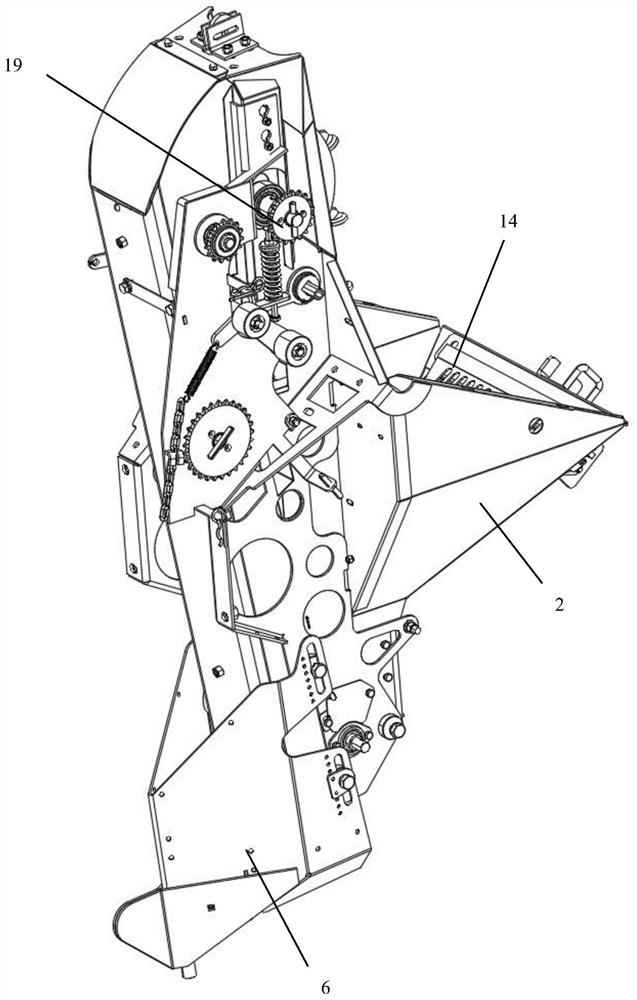

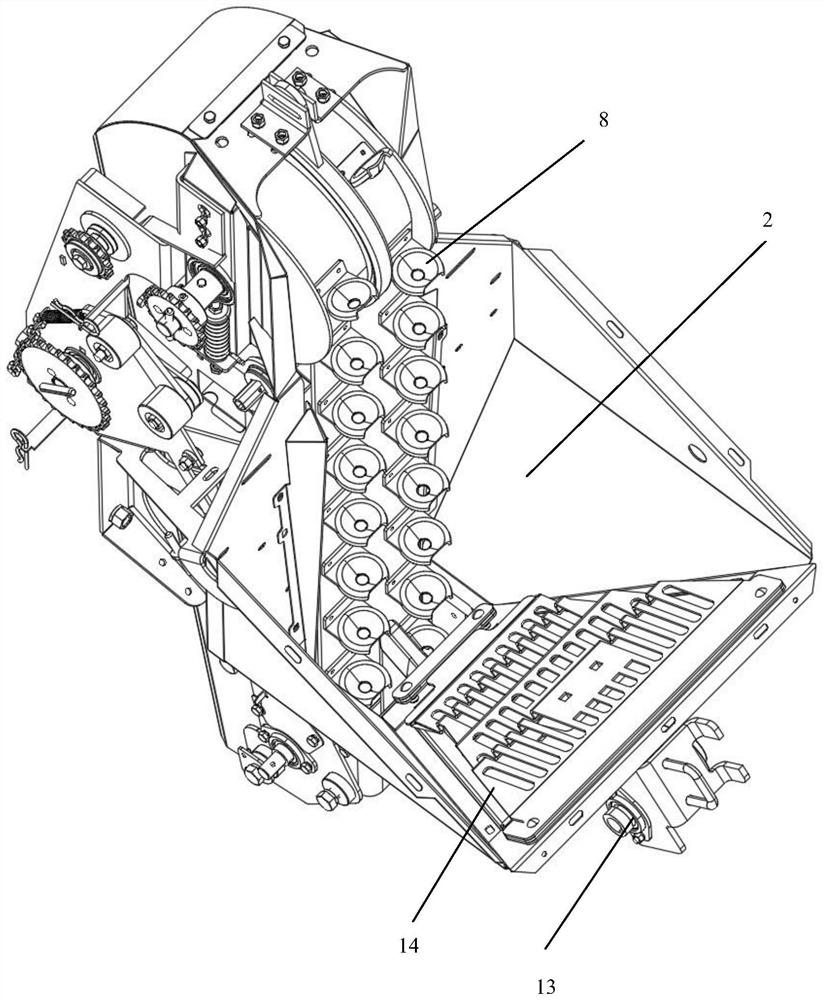

[0025] Such as Figure 1 to 8 As shown, the potato active delivery device for the potato seeder includes an eccentric drive mechanism 13 and a fluid plate 14; a plurality of layers of folding boss 25, a guide The uppermost guide slide 24 is the uppermost guide slide 24, and the eccentric drive mechanism 13 includes a drive bearing 16, a plug pin shaft 22, an eccentric wheel 21, an arm 20, and a connecting plate 18; The eccentric wheel 21 is a step axis, and the eccentric wheel 21 is fixed to the driving bearing 16 inner ring, and the eccentric wheel 21 is provided with an eccentric hole 17, and the flow drive shaft 5 is fixed to the eccentric hole 17; the plug pin 22 is The drive bearing 16 is fixedly connected, and the turning arm 20 is fixedly connected to the shaft sleeve 23, the plug pin shaft 22 is inserted into the center hole of the bushing 23, and can be rotated in the central hole, the other end of the turning arm 20 and the guide The flow plate 14 constitutes a fixed connect

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap