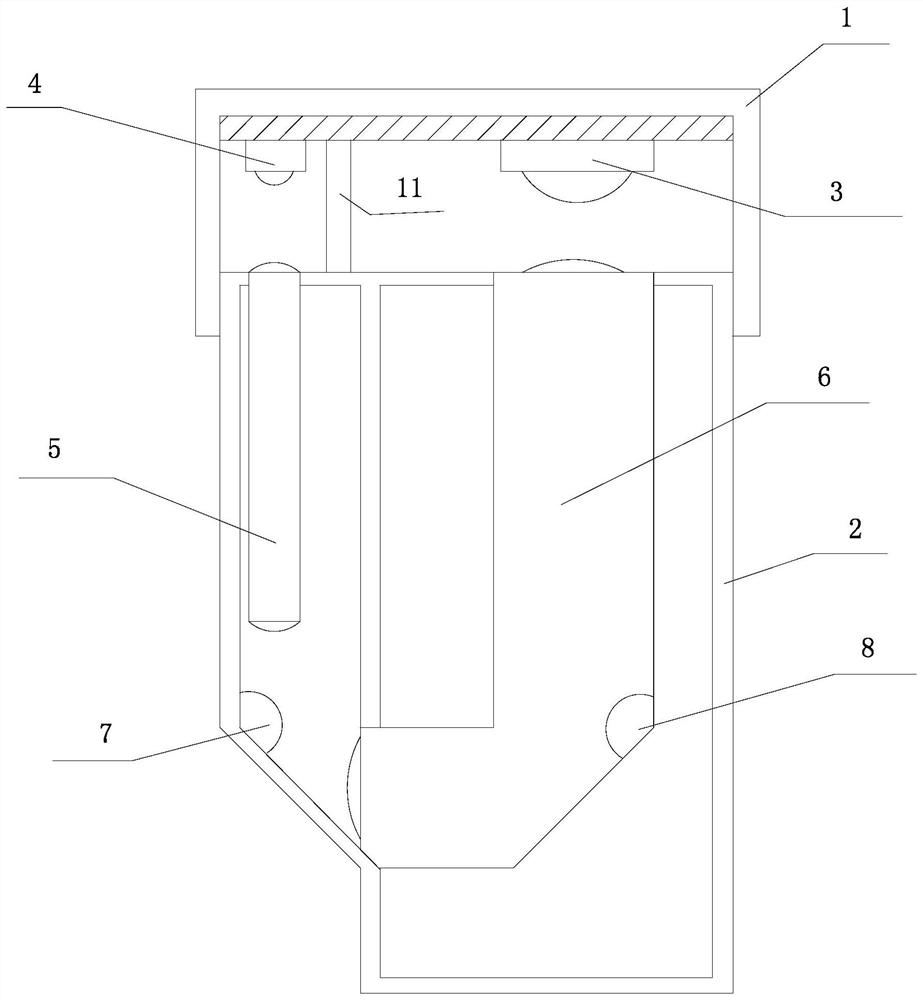

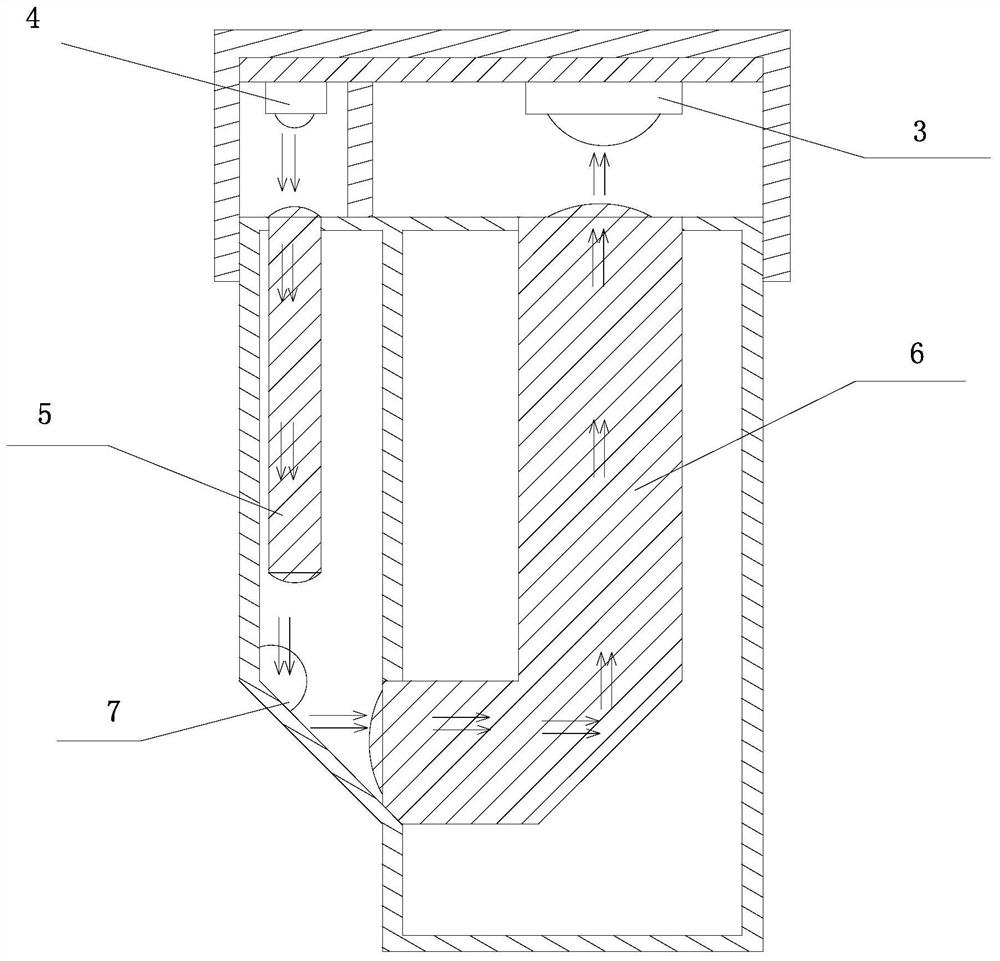

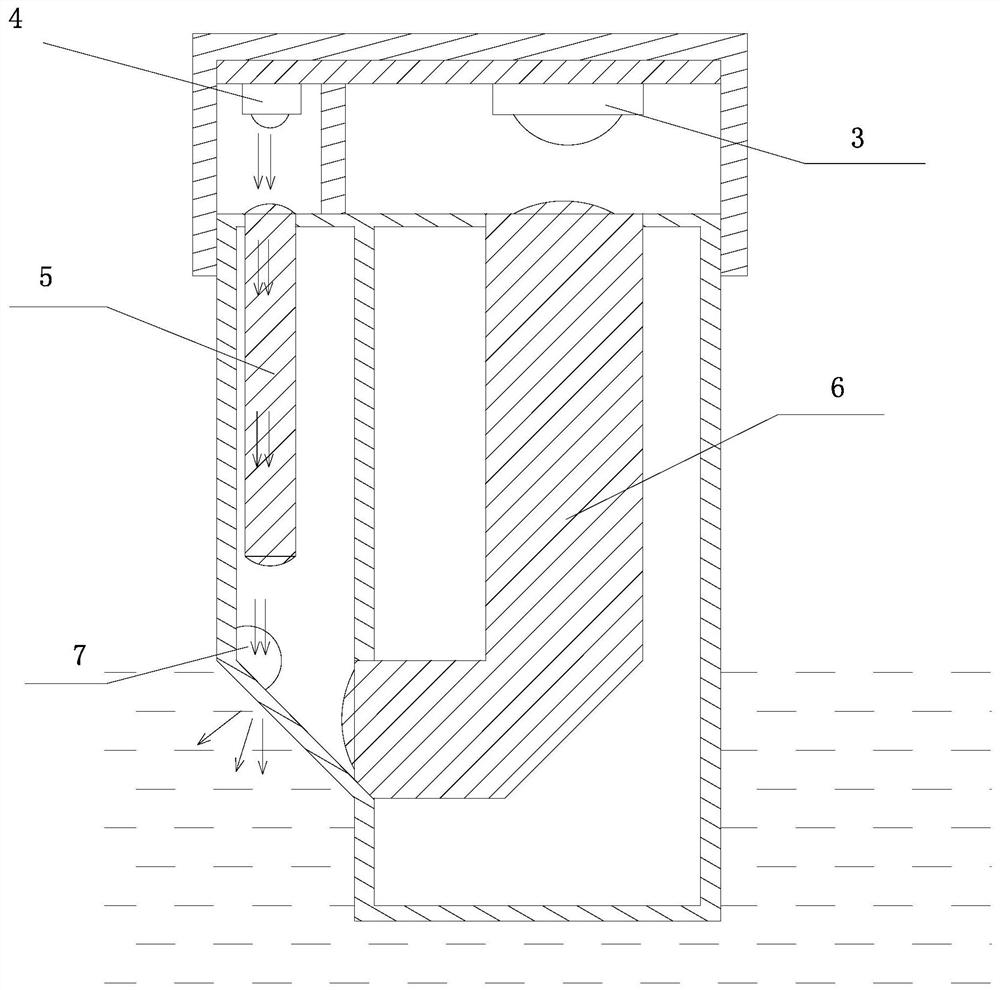

Photoelectric liquid level sensor

A sensor and opto-hydraulic technology, applied in the field of sensors, can solve the problems of large installation location limitations, large signal interference, short measurement distance, etc., and achieve the effects of accurate and stable detection results, less stray light interference, and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more obvious and comprehensible, specific embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the specific details described below are only some embodiments of the present invention, and the present invention can also be implemented in many other embodiments different from those described here. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0033] It should be noted that when an element is referred to as being “fixed” to another element, it can be directly on the other element or there can also be an intervening element. When an element is referred to as being "connected to" another element, it can be directly connected to the other elem

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap