Micro-nano drag reduction structure for high-altitude and high-speed environment

An environmental and micro-nano technology, applied in the direction of drag reduction, affecting the air flow passing through the surface of the aircraft, aircraft parts, etc., can solve the problems of complex structure and poor drag reduction effect of the drag reduction device, achieve simple structure and reduce frictional resistance , the effect of increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] The present invention will be described in detail below with reference to the specific embodiments. The following examples will help to further understand the present invention in any form of technicrat, it will be further understood by those skilled in the art. It should be noted that several variations and improvements can be made without departing from the concept of the present invention without departing from the present invention. These are all of the scope of protection of the present invention.

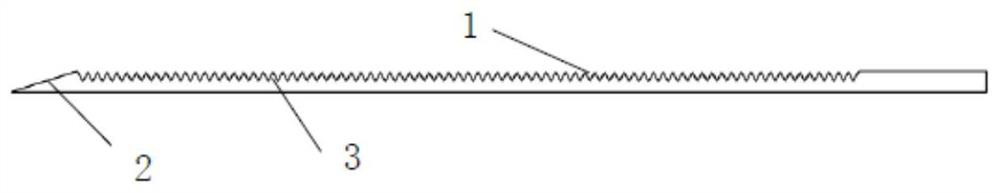

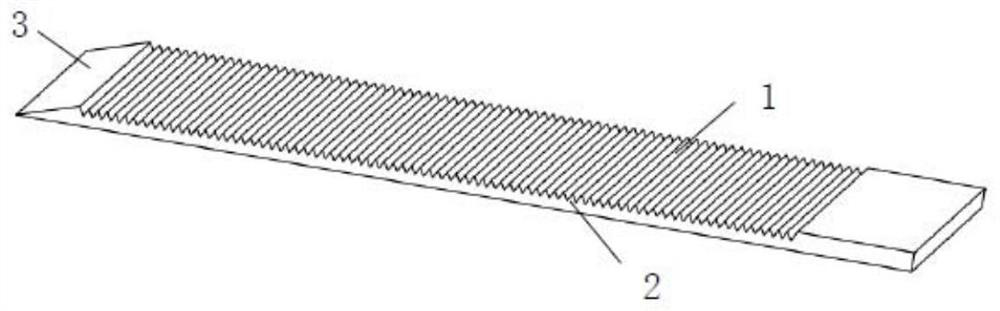

[0023] Such as figure 1 As shown, a microbial reduction structure for a high-altitude high-speed environment provided in accordance with the present invention includes a groove 1 that etchesing the outer surface of the aircraft by laser micronide manufacturing technique, further comprising integrally forming an outer surface of the aircraft. The wind flashes 2, and the air winding surface 2 is located on the wind side of the trench 1. The flight height of the aircraft is high

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap