Construction method using self-suspending water fracturing propping agent

A technology for water fracturing and construction methods, applied in chemical instruments and methods, mining fluids, earthwork drilling, etc., can solve the problems of long cycle, inconvenient construction, high cost, etc., to reduce damage, save costs, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

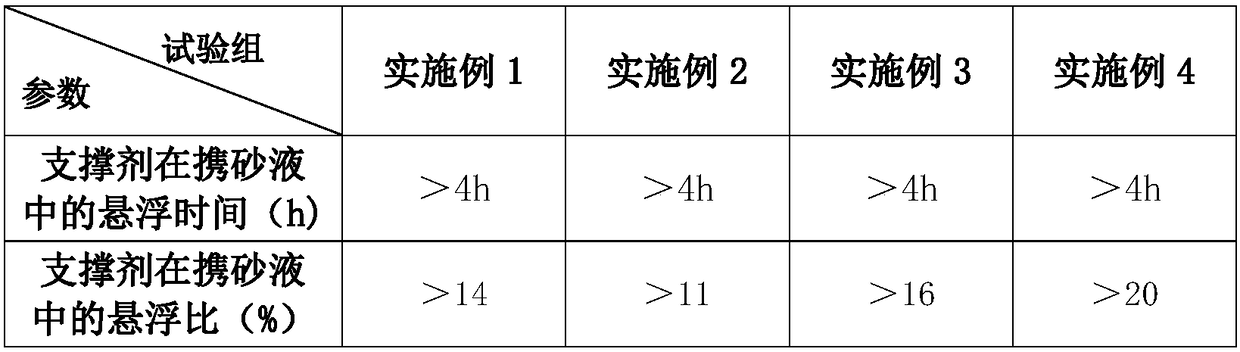

[0048] Example 1

[0049] The construction method using self-suspending clean water fracturing proppant includes the following steps:

[0050] (1) Use a high-pressure pump truck to pump natural water into the downhole reservoir at a displacement of 2 cubic meters per minute for fracturing to form initial fractures;

[0051] (2) Continuously add clean water as the sand-carrying fluid in the sand mixer, and at the same time add the self-suspending clean water fracturing proppant at a displacement of 2.2 cubic per minute to make a sand-carrying fracturing fluid, and the sand mixing time is 10s; The volume ratio of the clean water fracturing proppant to the sand-water volume of the sand-carrying liquid is 40%, and the relationship between the sand mixing speed Y and the sand-water volume ratio X is controlled at Y = 118.35X 0.1918 ;

[0052] (3) After the initial fractures are formed, a high-pressure pump truck is used to continuously pump the sand-carrying fracturing fluid into the initial

Example Embodiment

[0061] Example 2

[0062] The construction method using self-suspending clean water fracturing proppant includes the following steps:

[0063] (1) Use a high-pressure pump truck to pump natural water into the downhole reservoir at a displacement of 2.5 cubic meters per minute for fracturing to form initial fractures;

[0064] (2) Continuously add clean water as the sand-carrying fluid in the sand mixer, and at the same time add self-suspending clean-water fracturing proppant at a displacement of 2.6 cubic per minute to make a sand-carrying fracturing fluid with a mixing time of 12s; self-suspension The volume ratio of the clean water fracturing proppant to the sand-water volume of the sand-carrying fluid is 45%, and the relationship between the sand mixing speed Y and the sand-water volume ratio X is controlled at Y = 118.35X 0.1918 ;

[0065] (3) After the initial fractures are formed, a high-pressure pump truck is used to continuously pump the sand-carrying fracturing fluid into the in

Example Embodiment

[0074] Example 3

[0075] The construction method using self-suspending clean water fracturing proppant includes the following steps:

[0076] (1) Use a high-pressure pump truck to pump natural water into the downhole reservoir with a displacement of 1.5 cubic meters per minute for fracturing to form initial fractures;

[0077] (2) Continuously add river water as a sand-carrying fluid in the sand mixer, and at the same time add a self-suspending clean water fracturing proppant at a displacement of 3 cubic meters per minute to make a sand-carrying fracturing fluid with a sand mixing time of 15s; self-suspension The volume ratio of the clean water fracturing proppant to the sand-water volume of the sand-carrying fluid is 50%, and the relationship between the sand mixing speed Y and the sand-water volume ratio X is controlled at Y = 118.35X 0.1918 ;

[0078] (3) After the initial fractures are formed, a high-pressure pump truck is used to continuously pump the sand-carrying fracturing fluid

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap