Double-head pay-off machine

A technology of pay-off machine and pay-off motor, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., and can solve the problem of waste of labor for I-shaped wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

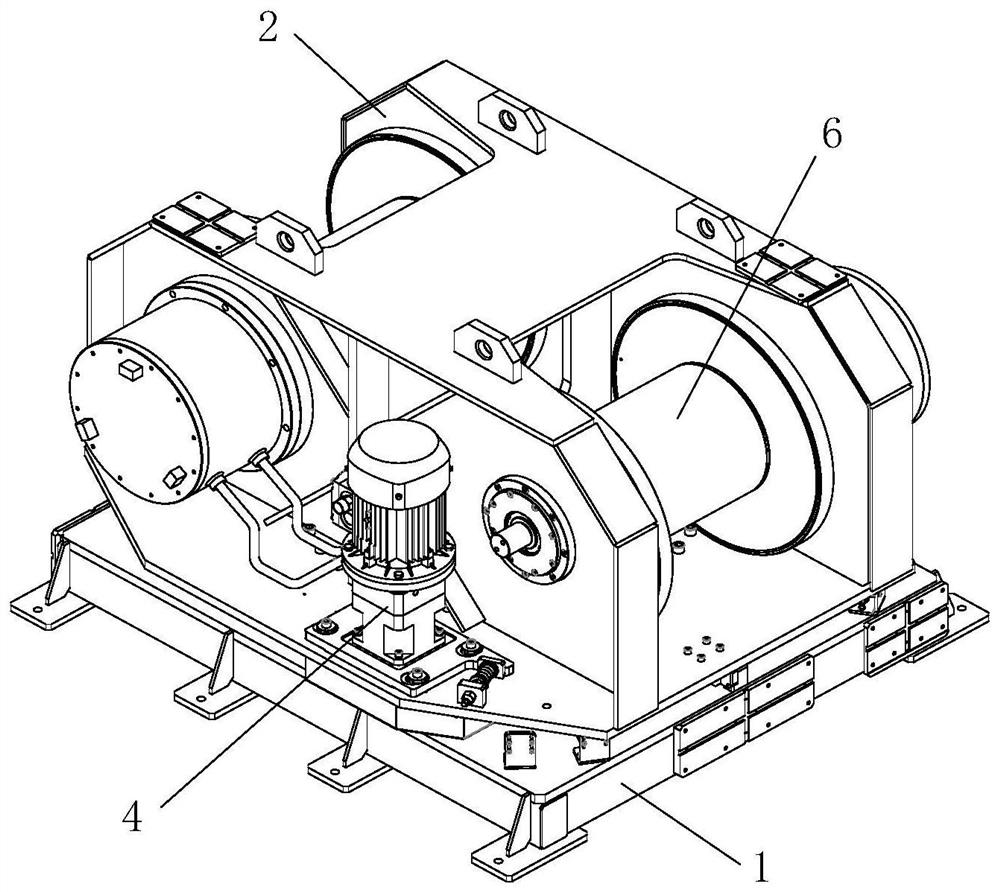

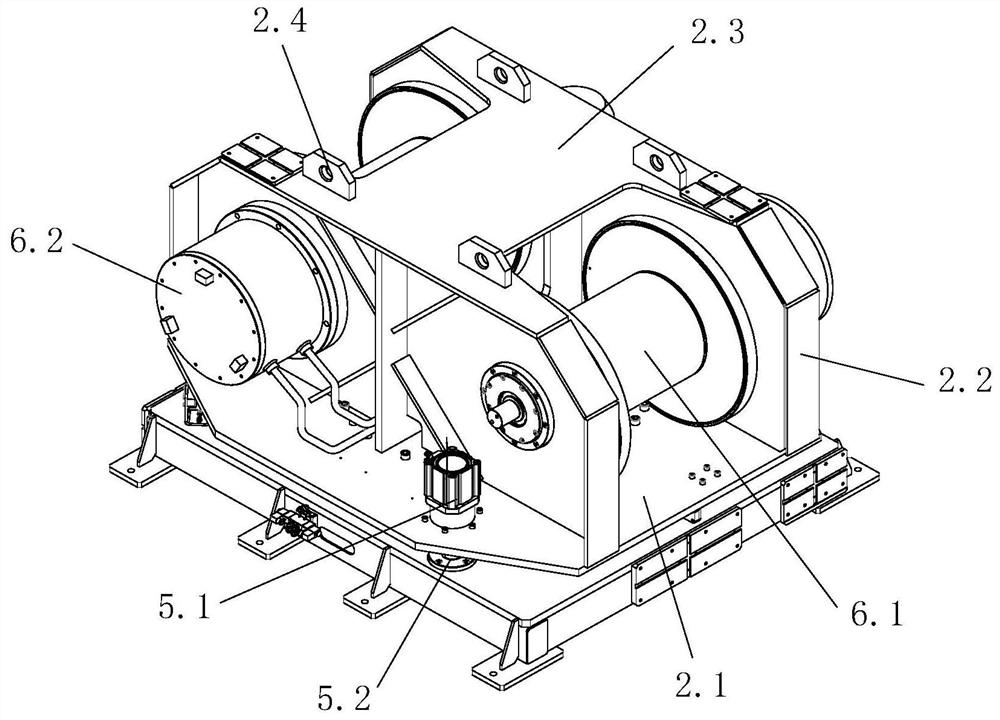

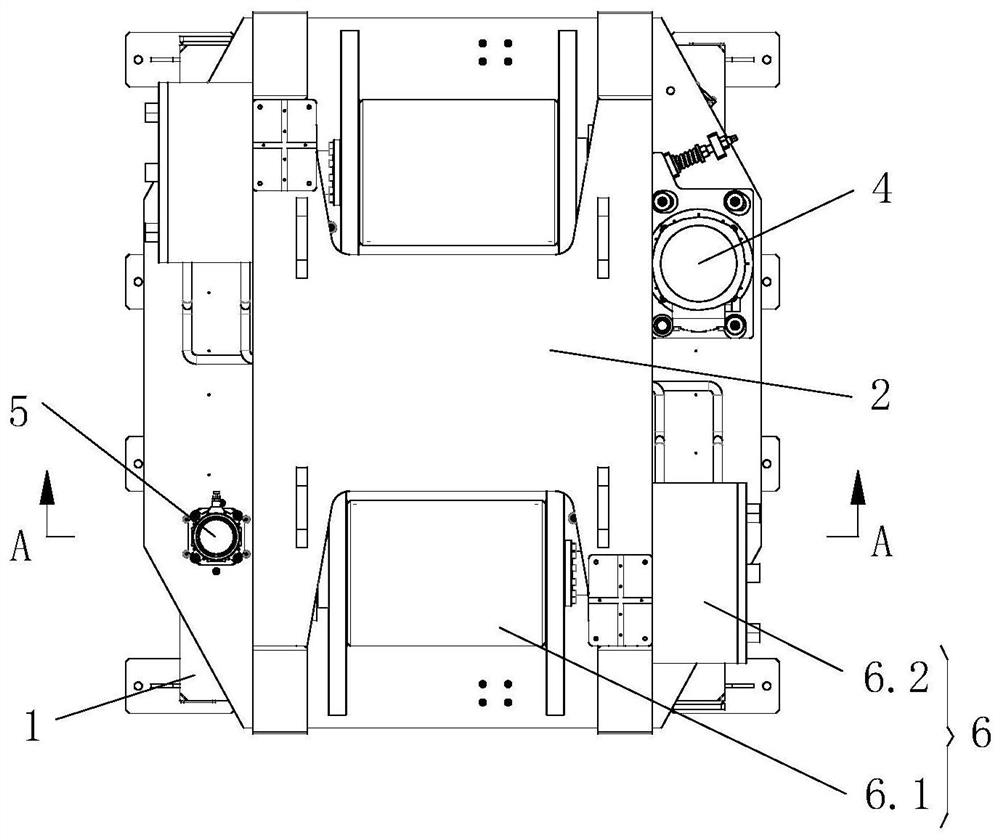

[0021] See Figure 1 to Figure 4 , the present embodiment provides a double-head pay-off machine, including a pay-off machine chassis 1, an I-wheel fixed frame 2, a slewing bearing 3, a rotating motor 4, a positioning device 5 and two pay-off devices 6; specific structure as follows:

[0022] The I-shaped wheel fixed frame 2 is installed on the pay-off machine chassis 1 through the slewing bearing 3. The I-shaped wheel fixed frame includes a frame bottom plate 2.1, a frame bracket 2.2 and a frame top plate 2.3, and the frame bracket is parallel and symmetrical. Set two between the rack bottom plate and the rack top plate. The slewing bearing 3 has an inner ring and an outer ring, the inner ring of the slewing bearing is connected and fixed with the pay-off

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap