Outer-layer plastic bag sealing equipment for soap packaging

A sealing equipment and packaging technology, applied in the field of outer plastic bag sealing equipment for soap packaging, can solve the problems of soap shaking, bag swelling, easy misalignment, etc., and achieve the effect of preventing liquid deformation and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example

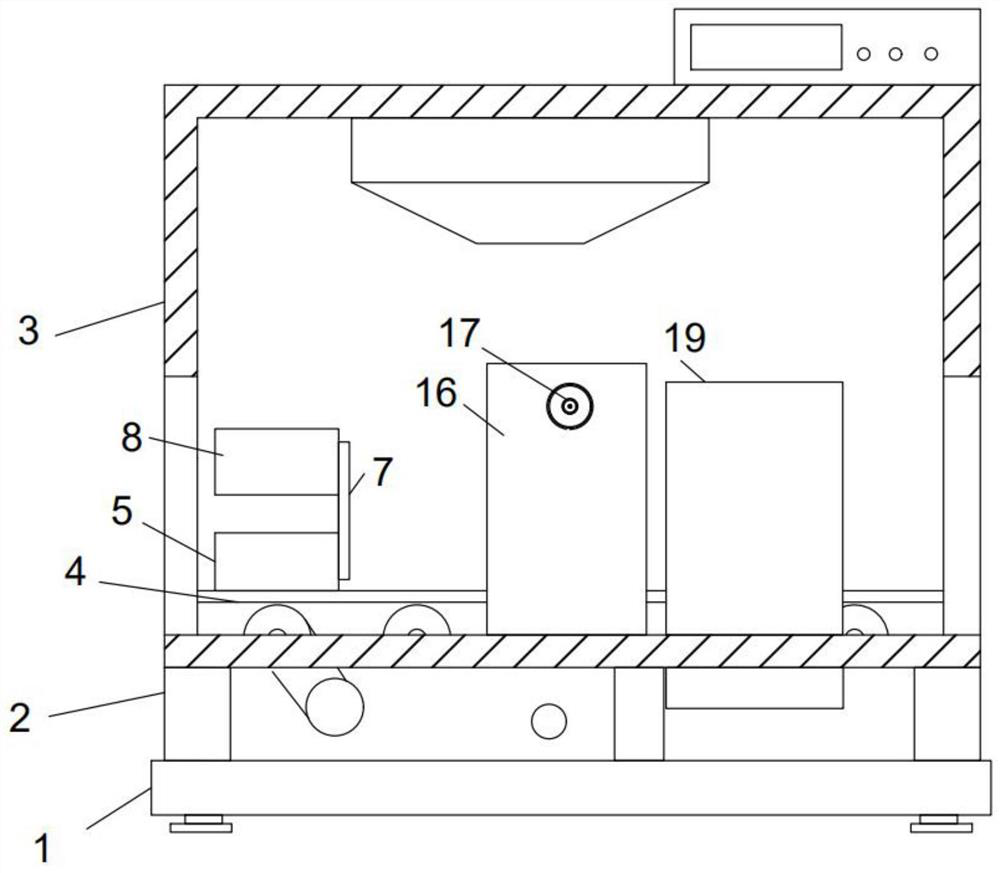

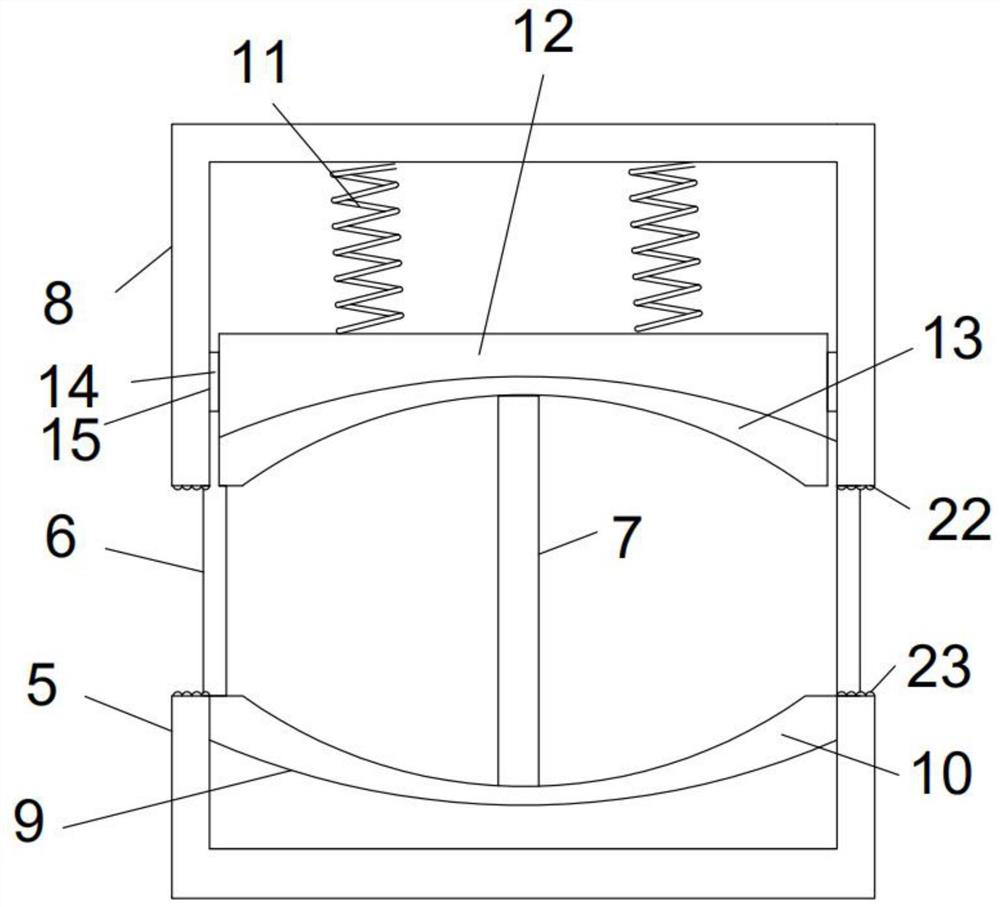

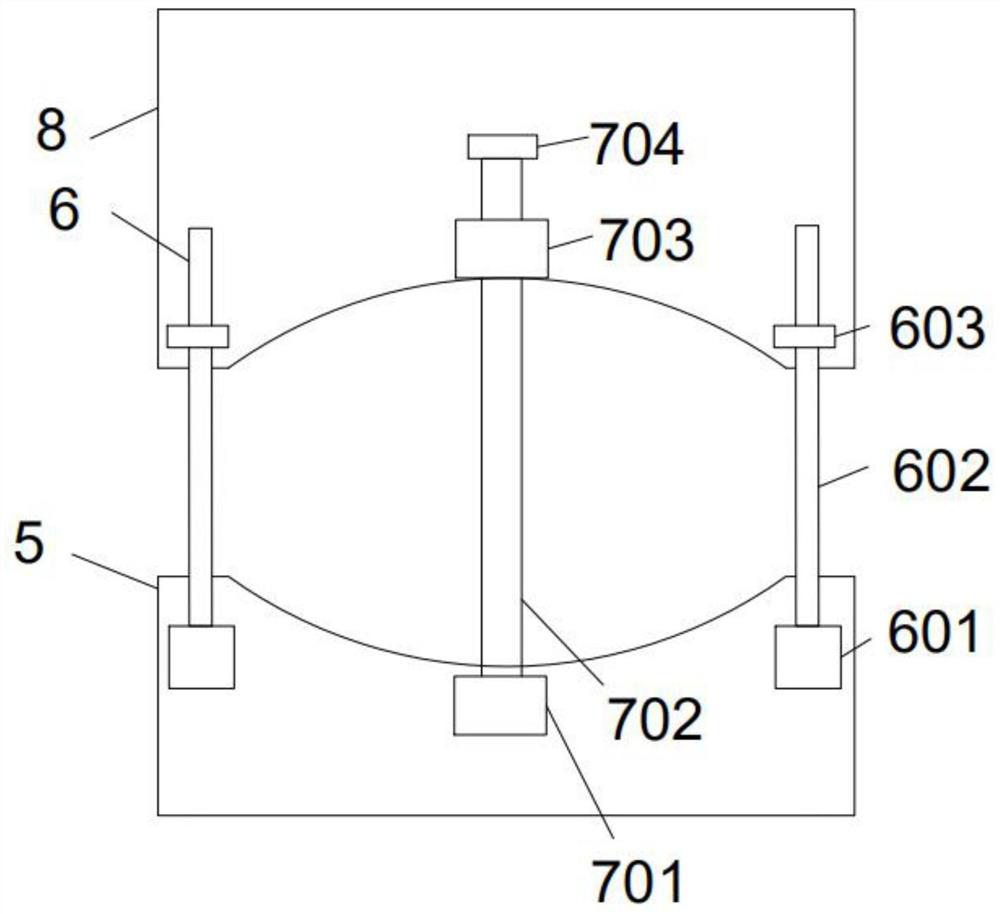

[0032] see Figure 1-Figure 3 , an outer plastic bag sealing device for soap packaging, comprising a base 1, the top of the base 1 is fixedly connected with a frame 2, the top of the frame 2 is fixedly connected with a cabinet 3, and the inside of the cabinet 3 is fixed Conveyor belt 4 is installed, and the top left side of described conveyer belt 4 is fixedly installed with fixed chassis 5, and the right front end and rear end of described fixed chassis 5 are all fixedly installed with transmission mechanism 6, and described fixed chassis 5 A guide mechanism 7 is fixedly installed in the middle part of the right side of the guide mechanism 7, and a fixed top frame 8 is fixedly installed on the left upper end of the guide mechanism 7. The top of the fixed bottom frame 5 is provided with a positioning groove 9, and the fixed bottom frame 5 is located in the positioning The position of the slot 9 is fixedly connected with a first cushion 10, the bottom of the fixe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap