Manufacturing method of blast furnace cooling wall

A manufacturing method and technology of cooling wall, applied in the field of metallurgical equipment, can solve the problems of high manufacturing cost and overall bulky cooling wall, and achieve the effect of reducing volume and weight and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0041]In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are merely intended to illustrate the invention and are not intended to limit the invention.

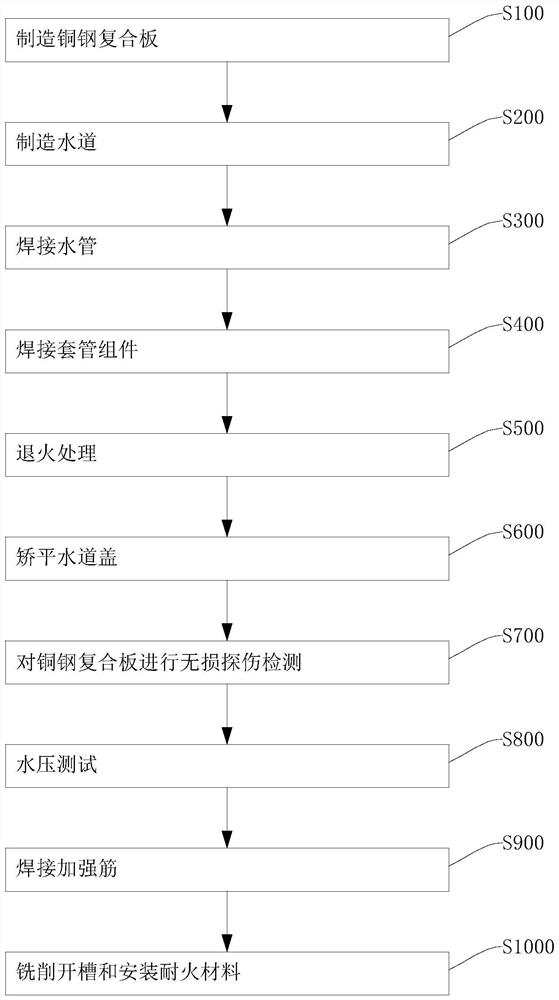

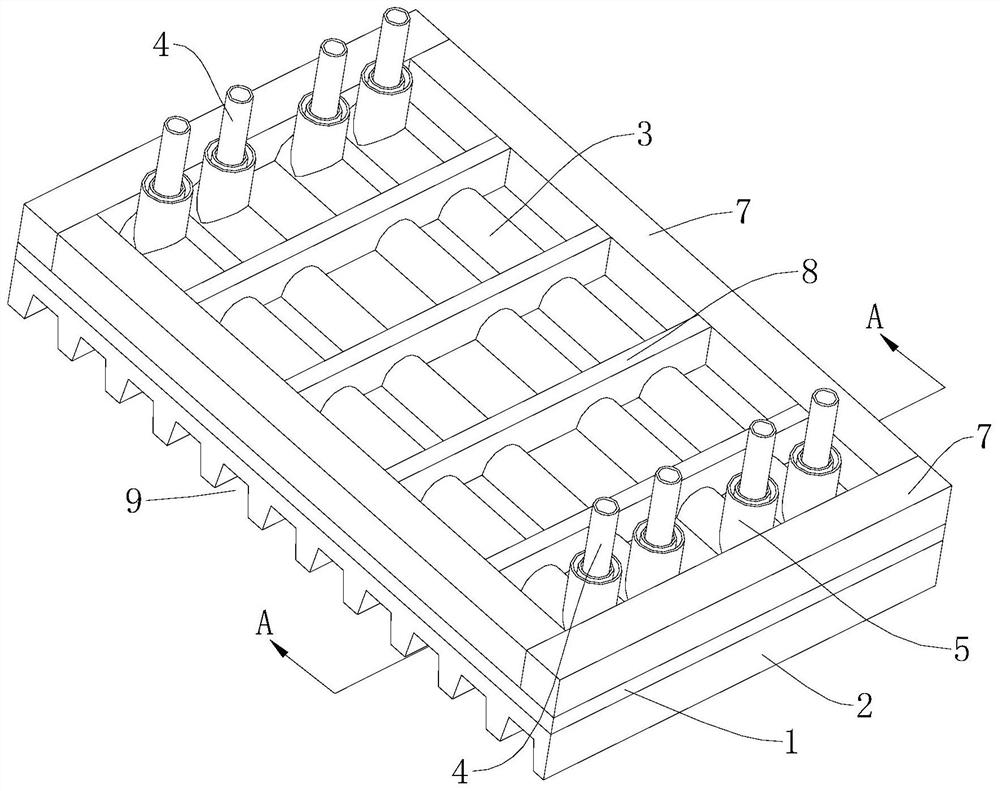

[0042]SeeFigure 1 to 4 The method of manufacturing a blast furnace cooling wall provided by the present invention will now be described.figure 1 A implementation process of a manufacturing method of a blast furnace cooling wall provided in accordance with an embodiment of the present invention is shown, and the process is detailed as follows:

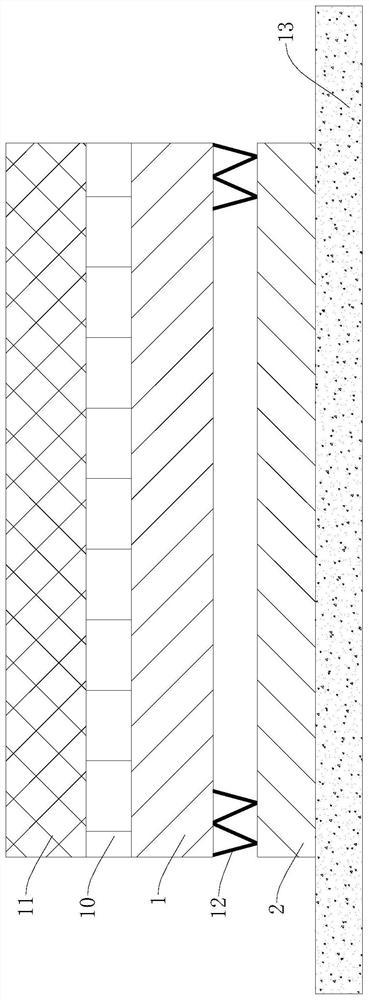

[0043]In step S100, the manufacturing copper steel composite panel is performed, mainly including obtaining the steel sheet 1 and the copper plate 2, by connecting the steel sheet 1 to the copper plate 2 to obtain a copper steel composite pan

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap