Flip-lid mirror cosmetic-product packaging and method of manufacture thereof

A technology for cosmetics and packaging, which is applied in the field of manufacturing the above-mentioned clamshell cosmetic packaging and flip mirror cosmetic packaging, which can solve the problems of sound generation, locking mechanism is not independent, hardening, etc., and achieve the effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054]The following detailed description shows the embodiments of the present disclosure and how thereof can be implemented. Although some of the modes of the present disclosure have been disclosed, those skilled in the art will recognize that other embodiments for performing or practicing the present disclosure are also possible.

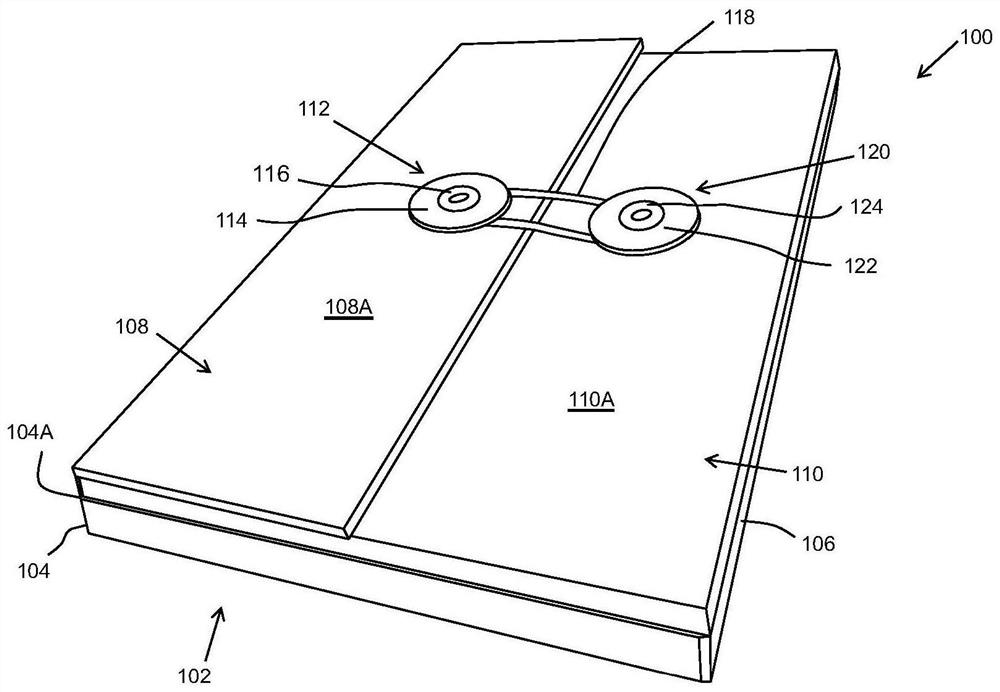

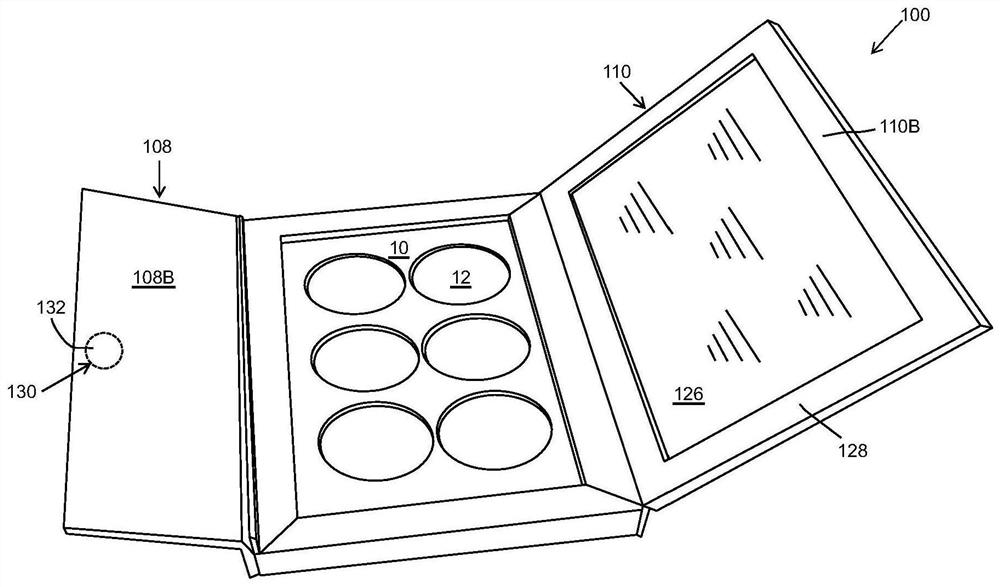

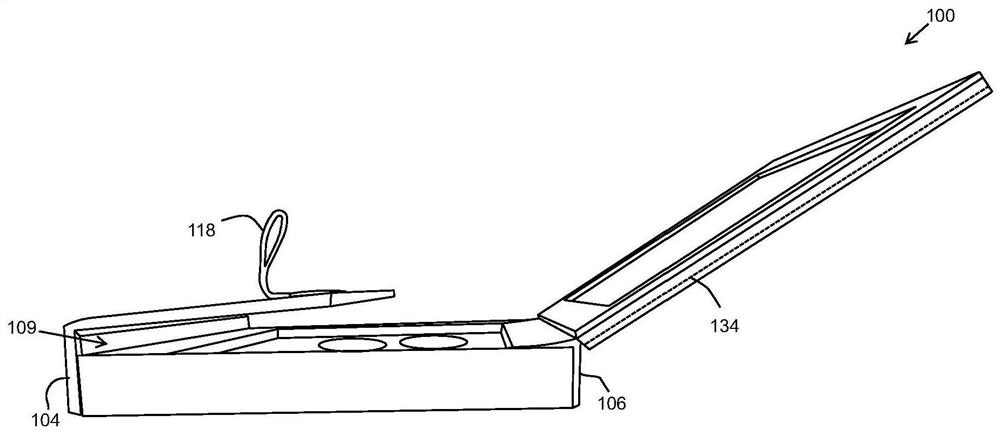

[0055]In one aspect, a flip mirror cosmetic packaging, wherein the flip mirror cosmetic packaging includes:

[0056](i) The base unit includes a tray having a plurality of types of cosmetics set on the tray in the space in the array, and the base unit has a first fine side and second in the opposite side of the susceptor unit. Elongate side;

[0057](ii) Half-cover, pivotally attached to the first fine side, has a housing gap;

[0058](iii) The lens cover is pivotally attached to the upper edge of the second elongated side, wherein the edge of the lens cover is adjacent to the second fine side to hold the lens in a tilt pivot when the lens cover is in an open state. An

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Horizontal width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap