Power-on reset circuit with low power consumption, small area and high precision

A small-area, high-precision technology, applied in the direction of electrical components, electronic switches, pulse technology, etc., can solve the problems of insufficient impedance, large temperature and process deviation at the flipping threshold point, and large power consumption, etc., to reduce the area , improve robustness, and ensure correct results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0043] Example

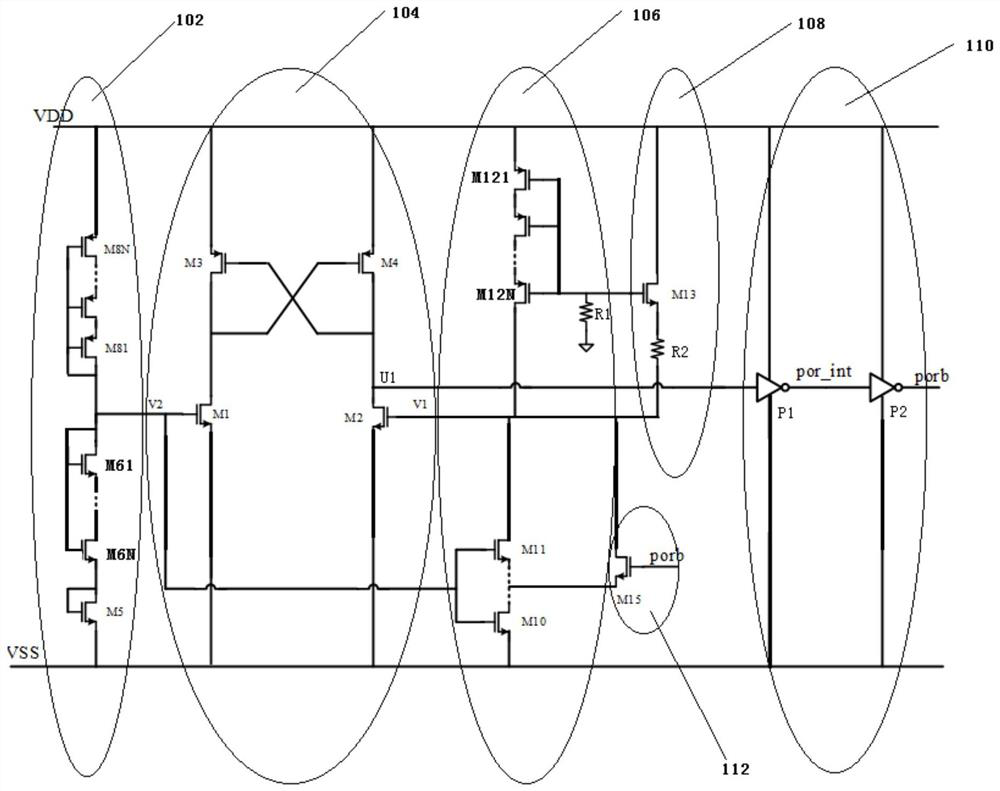

[0044] figure 2 A connection diagram of a power-on reset circuit with low power consumption, small area and high precision according to the present invention is shown.

[0045] like figure 2As shown, the power-on reset circuit with low power consumption, small area and high precision includes a power supply, a first voltage divider module 102, a second voltage divider module 106, a comparison module 104, a pull-up module 108, a hysteresis module 112 and a reverse module 110; the first voltage division module 102 is connected to the power supply, the comparison module 104 and the second voltage division module 106 respectively, and provides the first input voltage for the comparison module 104; the second voltage division module 106 is respectively connected to the power supply, the first voltage division module 102 , the comparison module 104, the pull-up module 108 and the hysteresis module 112 are connected, the second voltage divider module provides the se

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap