Facility electric vegetable transplanter

A transplanter, electric technology, applied in the field of agricultural machinery, can solve the problems of affecting crops and personnel health, large field transplanter models, a lot of harmful smoke, etc., to achieve less auxiliary labor, ease the frequency of seedling picking, land Flexible turning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] In this example, the vegetables are planted in the way of plug seedling cultivation. Plug seedling cultivation is the mainstream production mode of modern agricultural production, which can quickly and mass-produce vegetables and flowers. The following advantages: saving the amount of seeds, reducing production costs; neat emergence, maintaining the consistency of plant seedling growth; no damage to the root system during transplanting, rapid seedling growth, high survival rate, etc.

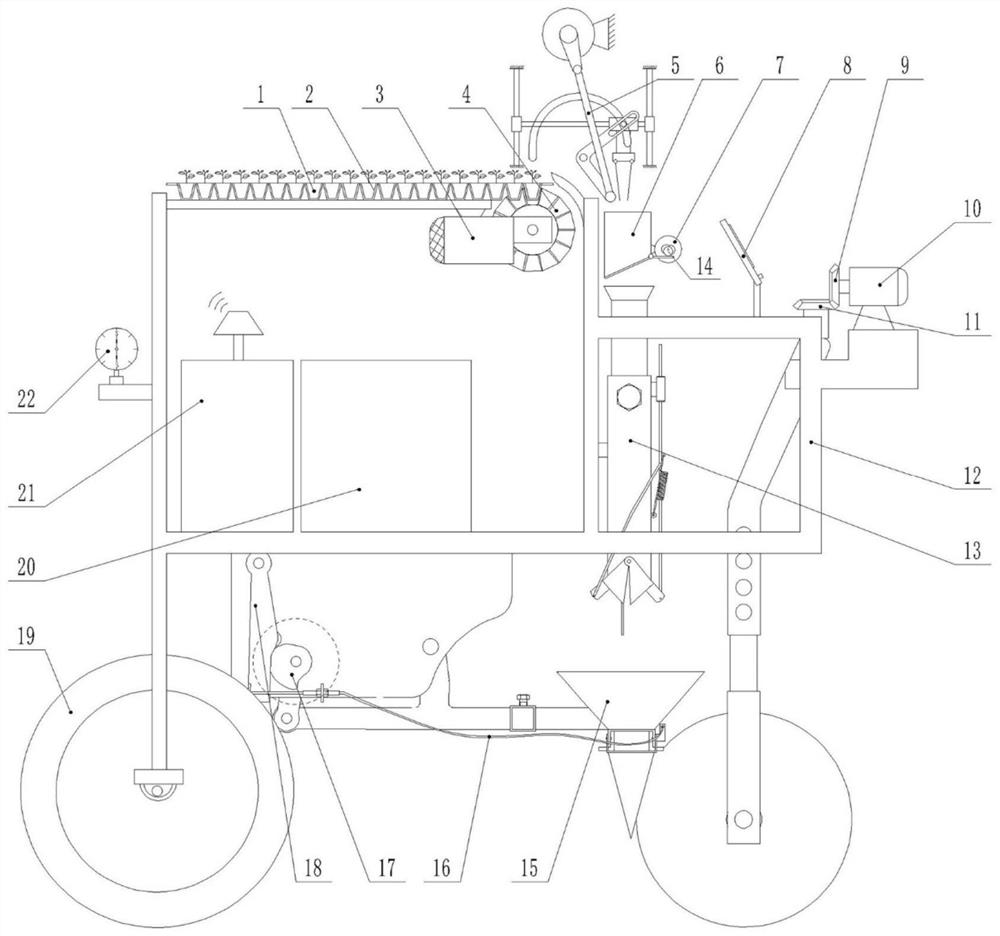

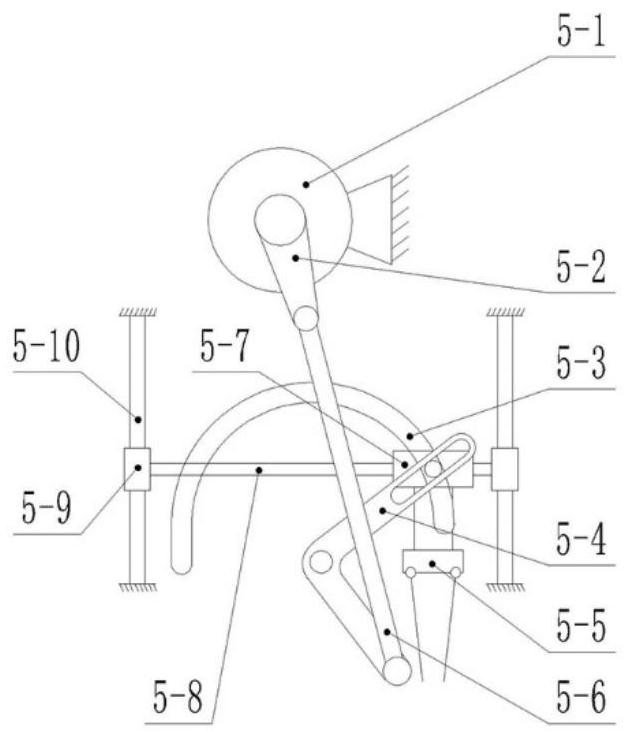

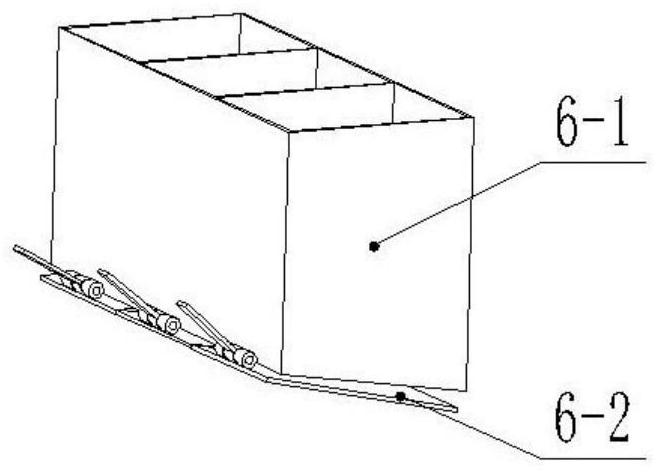

[0023] The facility electric vegetable transplanting machine of present embodiment, as Figure 1-6 Shown, comprise sending seedling mechanism 3, get seedling mechanism 5, throw seedling mechanism 6 and planting mechanism 15.

[0024] Such as figure 1 As shown, the seedling delivery mechanism 3 includes a seedling delivery wheel 4 installed on the frame 12 and a seedling delivery motor 3 that drives the rotation of the seedling delivery wheel 4. The periphery of the seedling delivery wheel 4

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap