Vortex light generating device and manufacturing method thereof

A technology for generating devices and manufacturing methods, applied in optics, optical components, instruments, etc., can solve the problems of low conversion efficiency of vortex light, phase distortion, poor purity, etc., to improve conversion efficiency, eliminate phase distortion, and improve conversion purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

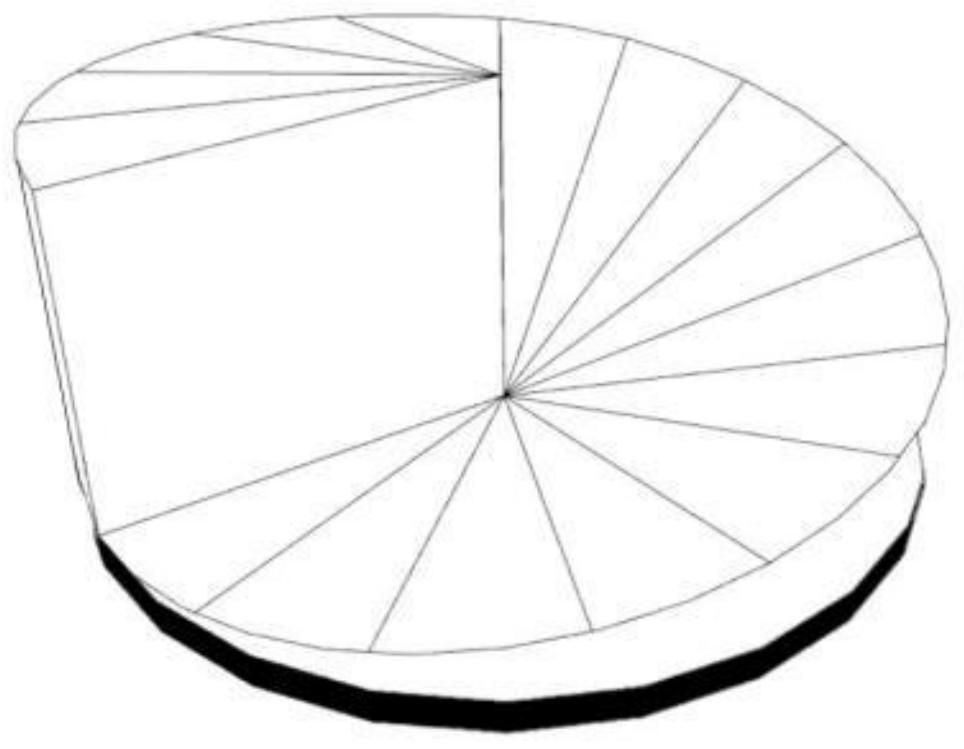

[0032] Manufacturing a vortex light generating device, comprising the steps of:

[0033] (1) Grinding and polishing the silica material glass substrate into a cylinder;

[0034] (2) Gold film is selected as the material of the reflective spiral phase plate, the wavelength λ of the incident laser is selected as 800nm; the topological charge l is selected as 1;

[0035] (3) The ambient material of the reflective spiral phase plate is air, and the refractive index of air is known to be 1.00028;

[0036] (4) It is known that the refractive index of the gold film is 1.183, and the difference between the refractive index of the air and that of the air results in Δn of 0.342;

[0037] (5) Bring Δn, λ and l into the formula H=lλ / Δn, and H can be obtained as 4.378um;

[0038] (6) Plating reflective films of different heights on the substrate from low to high in the counterclockwise direction to form stepped steps, that is, to complete the manufacture of a vortex light generating devic

Embodiment 2-4

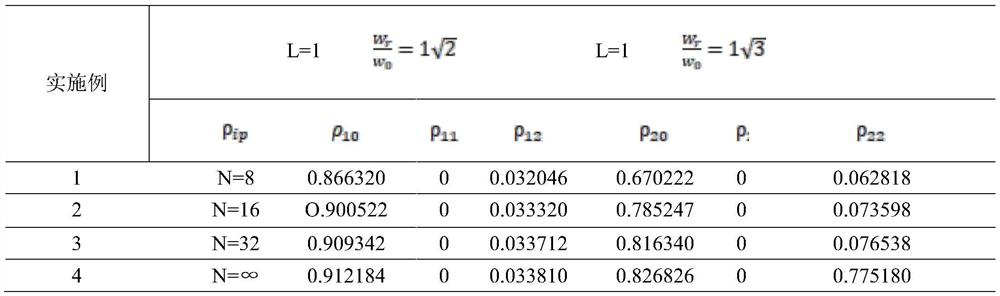

[0043] The raw materials and manufacturing methods used in the vortex light generating device manufactured in Examples 2-4 are the same as in Example 1, except that different step numbers, radial numbers and topological charges of the helical phase plate are selected, these The manufacturing parameters of the vortex light generating device in the embodiment and the performance parameters after the experiment are shown in Table 1.

[0044] Table 1 Conversion purity table of the spiral phase plate with p=0

[0045]

[0046] As shown in Table 1, it can be seen from the table that as the number of steps of the spiral phase plate increases, the conversion efficiency and conversion purity of the vortex laser gradually increase. When the topological charge of the spiral phase plate is 1 and the radial direction is 0, the spiral phase plate The number of steps is from 16 to infinity, and the conversion efficiency of the spiral phase plate is only increased by 1%. However, the manufact

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap