Construction process and method for pore-forming cast-in-place pile of rotary drilling rig

A technology of rotary drilling rig and construction technology, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc. It can solve the problems of affecting the stability of piles, reducing the stability of casing, and the failure of casing positioning, etc., so as to achieve convenient fixing, The effect of improving stability and increasing the force bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Embodiment one

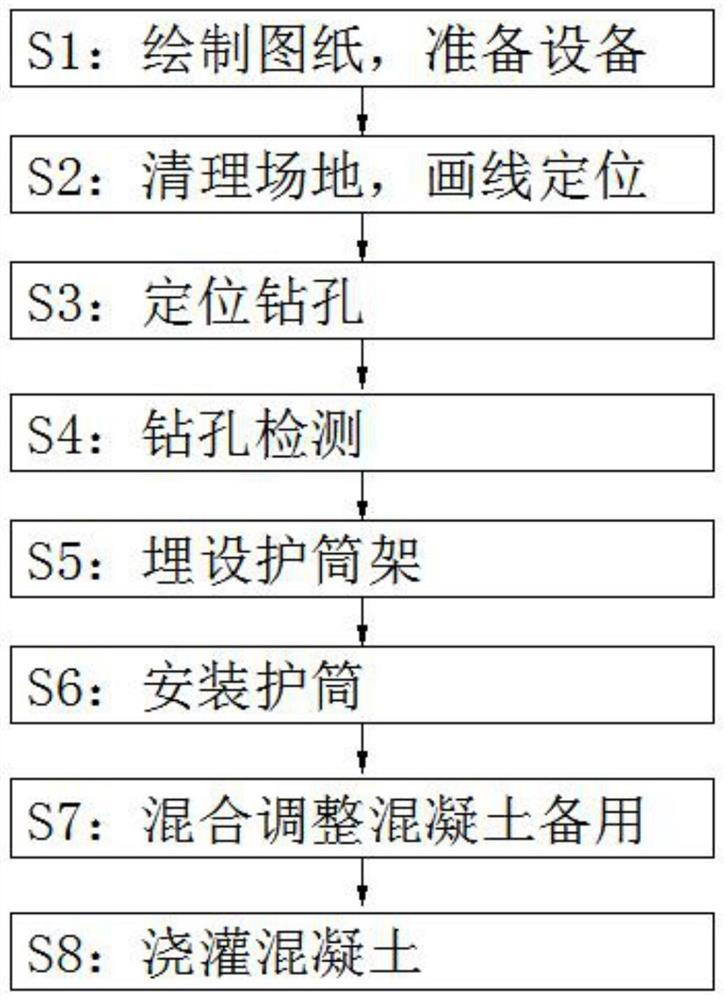

[0029] refer to figure 1 , a construction method of a rotary drilling rig to form a bored pile, comprising the following process steps:

[0030] S1: Draw drawings and prepare equipment;

[0031] S2: Clean up the site, draw a line for positioning;

[0032] S3: positioning drilling;

[0033] S4: drilling detection;

[0034] S5: Bury the casing frame;

[0035] S6: install the casing;

[0036] S7: mix and adjust the concrete for standby;

[0037] S8: Pouring concrete.

[0038] In this embodiment, scale drawings are installed in S1, and drilling equipment is prepared and checked.

[0039] In this embodiment, in S2, the site is cleaned and cleared according to the drawings, and the site is drawn and positioned.

[0040] In this embodiment, a rotary drilling rig is used to dig holes in S3. Firstly, holes for placing the casing are dug out, and then spread outwards to dig out holes for placing the casing frame.

[0041] In this embodiment, in S4, a press

Example Embodiment

[0047] Embodiment two

[0048] refer to figure 1 , a construction method of a rotary drilling rig to form a bored pile, comprising the following process steps:

[0049] S1: Draw drawings and prepare equipment;

[0050] S2: Clean up the site, draw a line for positioning;

[0051] S3: positioning drilling;

[0052] S4: drilling detection;

[0053] S5: Bury the casing frame;

[0054] S6: install the casing;

[0055] S7: mix and adjust the concrete for standby;

[0056] S8: Pouring concrete.

[0057] In this embodiment, scale drawings are installed in S1, and drilling equipment is prepared and checked.

[0058] In this embodiment, in S2, the site is cleaned and cleared according to the drawings, and the site is drawn and positioned.

[0059] In this embodiment, a rotary drilling rig is used to dig holes in S3. Firstly, holes for placing the casing are dug out, and then spread outwards to dig out holes for placing the casing frame.

[0060] In this embodiment, in S4, a press

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap