Flange heater

A heater and flange technology, applied in the field of heaters, can solve the problems of insufficient uniform heating, unsatisfactory heating, single heating method, etc., and achieve the effect of good heating effect and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

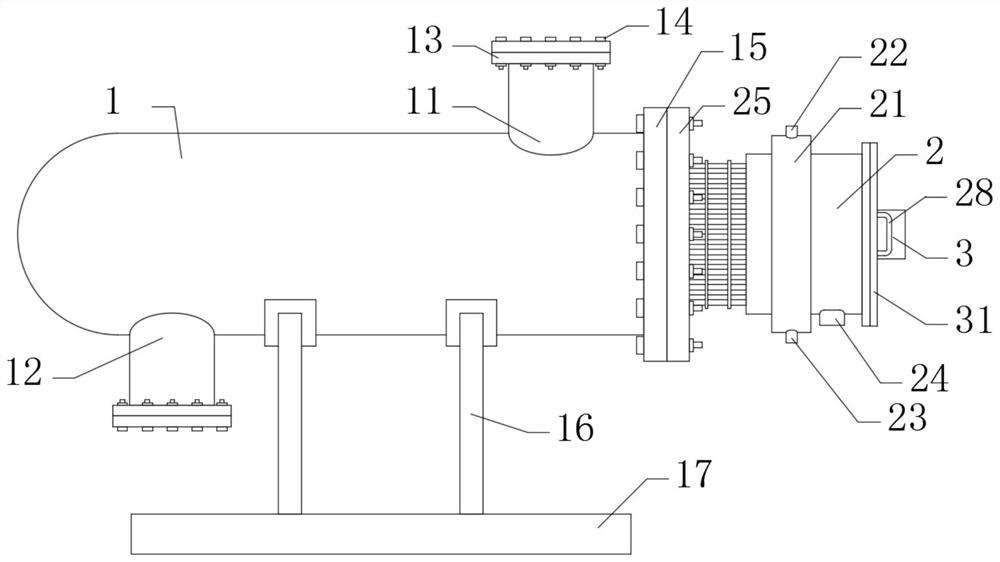

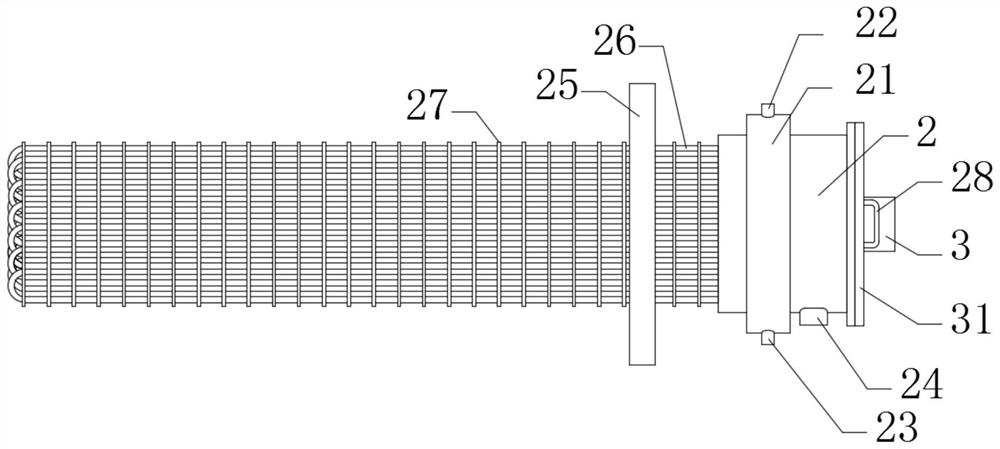

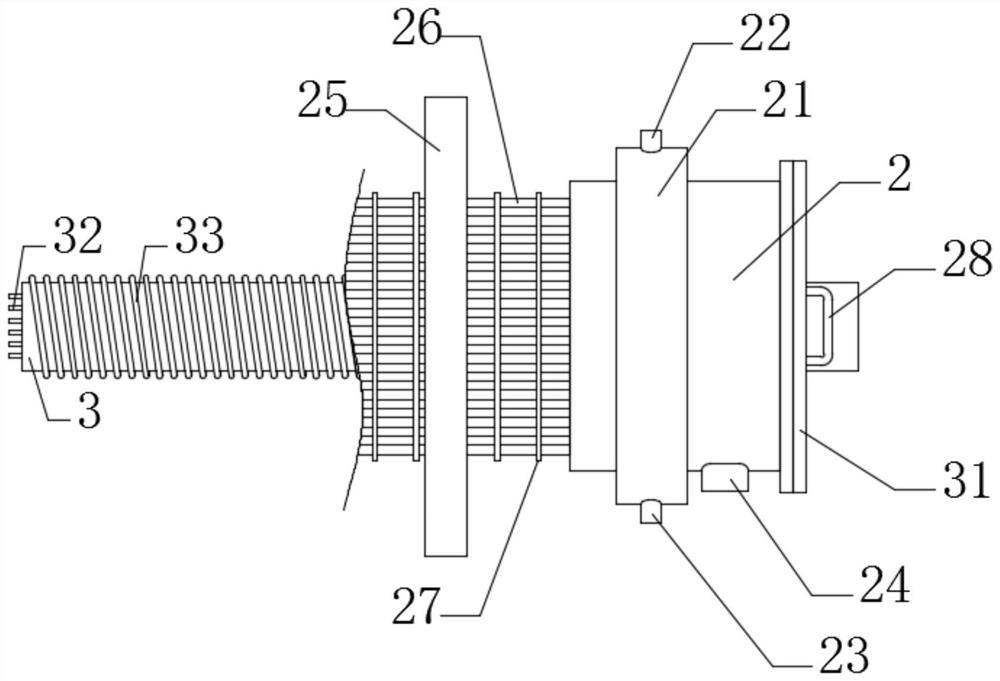

[0025] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 It is a schematic structural diagram of the overall front view of the present invention; figure 2 It is a schematic diagram of the main viewing mechanism of the control box of the present invention; image 3 It is a schematic diagram of the front half-section structure of the control box of the present invention; Figure 4 It is a schematic diagram of the side view structure of the outer air intake pipe of the present invention; specifically, a flange heater includes: a main body 1, an air inlet 11 is inlaid on the upper side of the main body 1, and a lower part of the main body 1 The side is inlaid with an exhaust port 12, and the air inlet 11 and the exhaust port 12 are welded with an air inlet flange 13, and bolts 14 are installed on the air inlet flange 13, and the main body 1 One end is welded with sealing flange 15.

[0026] In the control box 2, a fixed flange 25 is installed on one

Embodiment 2

[0031] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 It is a schematic structural diagram of the overall front view of the present invention; figure 2 It is a schematic diagram of the main viewing mechanism of the control box of the present invention; image 3 It is a schematic diagram of the front half-section structure of the control box of the present invention; Figure 4 It is a schematic diagram of the side view structure of the outer air intake pipe of the present invention; specifically, a flange heater includes: a main body 1, an air inlet 11 is inlaid on the upper side of the main body 1, and a lower part of the main body 1 The side is inlaid with an exhaust port 12, and the air inlet 11 and the exhaust port 12 are welded with an air inlet flange 13, and bolts 14 are installed on the air inlet flange 13, and the main body 1 One end is welded with sealing flange 15.

[0032] In the control box 2, a fixed flange 25 is installed on one

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap