Gas engine power plant and method of operating a gas engine power plant

A gas engine and power device technology, applied in the direction of engine components, combustion engines, engine control, etc., can solve the problem that energy cannot be used effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

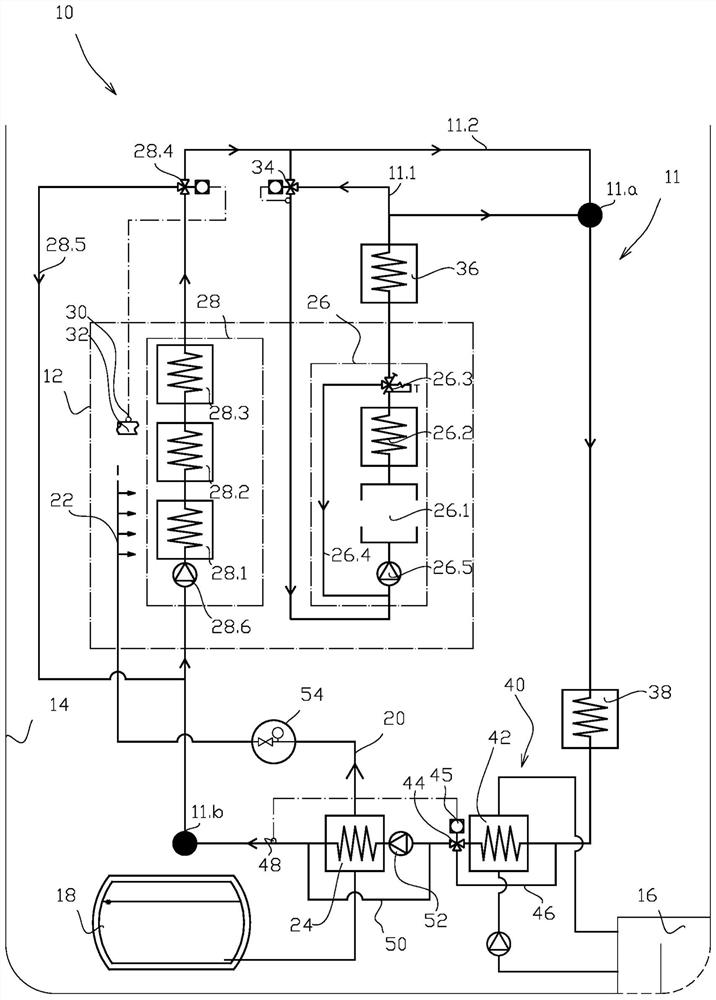

[0025] figure 1 A gas engine power plant 10 is schematically depicted comprising at least one dual fuel internal combustion engine 12 , hereinafter referred to as the engine. A dual fuel engine is a piston engine that can run on both gaseous and liquid fuels. When running in gas mode, the engine works according to the Otto process, in which a lean air-fuel mixture is used for combustion. When running in diesel mode, the engine works according to the Diesel process. The engine is optimized to run on gaseous fuel, and diesel fuel is used for backup fuel operation. During operation, switching between fuels occurs seamlessly without loss of power or speed. exist figure 1 Among them, the power plant 10 is in a sea vessel 14 for generating propulsion and / or electric power for the sea vessel 14 . The sea vessel is provided with sea suction tanks 16 which provide sea water in the sea vessel 14 for cooling purposes. Power-plant 10 includes cryogenic fuel storage, or cryogenic tank

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap